Method for measuring membrane temperature in metal organic chemical vapor deposition (MOCVD) equipment in real time and measuring device

A technology of chemical vapor deposition and metal-organic substances, which is applied in measuring devices, optical radiation measurement, radiation pyrometry, etc., can solve the problem that the change error of the stereoscopic acceptance angle of the receiving detector cannot be eliminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

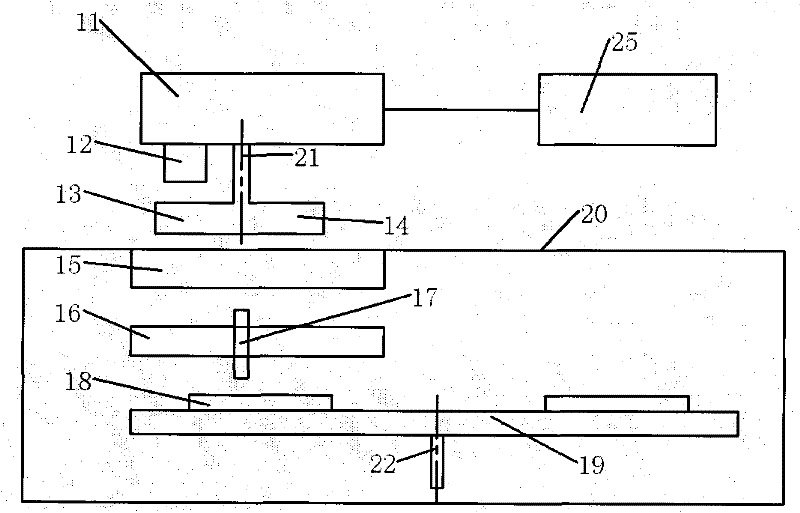

Embodiment 1

[0020] The basic principle of the non-contact optical temperature measurement method is Planck's distribution law, which reveals the distribution law of the wavelength of black body radiation energy at different black body temperatures, and its mathematical expression is as follows:

[0021] E ( λ , T ) = C 1 λ - 5 ϵ ( λ ) e C 2 / ( λT ) - 1 - - - ...

Embodiment 2

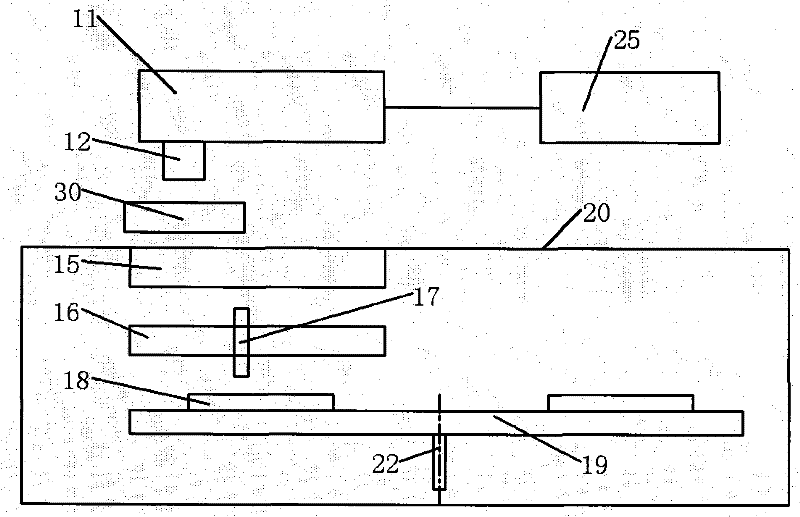

[0051] Embodiment 2 is the same as Embodiment 1, except that the device in this embodiment is composed of a data acquisition system 11 , an optical detector 12 , a grating 30 , and a data analysis and display system 25 . The epitaxial thin film 18 emits a spectrum, first passes through the spray hole 17, then passes through the test window 15 on the cavity 20 and enters the optical detector 12 by the spectroscopic grating 30. At this time, the wavelength split by the spectroscopic grating 30 is set to lambda 1 , through the data acquisition system 11 to detect and record the epitaxial film 18 at λ 1 Radiant power P at wavelength 1 , and then split another wavelength through the splitting grating 30 and set it as λ 2 , the data acquisition system 11 detects and records the epitaxial film 18 at λ 2 The radiation power under P 2 , and finally perform data processing and analysis in the data analysis and display system 25 to obtain the surface temperature. see figure 2 , th...

Embodiment 3

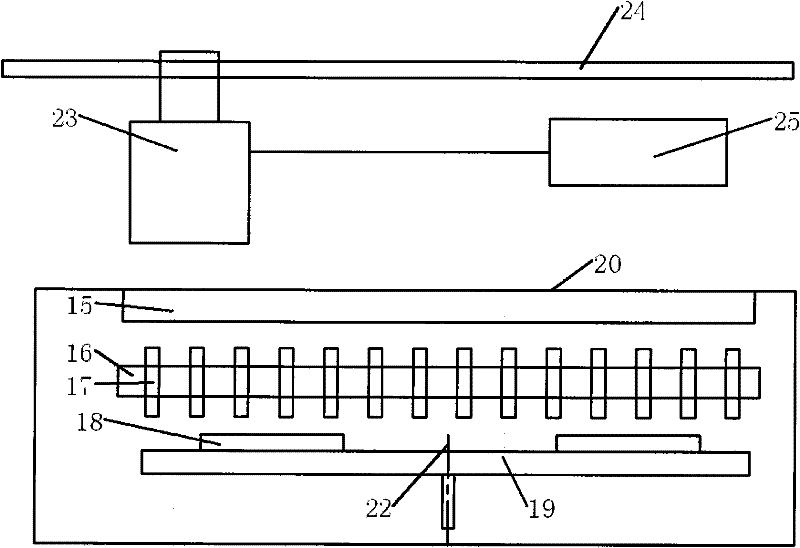

[0060] Embodiment 3 is the same as Embodiment 1, except that in this embodiment, a subsystem temperature measuring device composed of the data acquisition system 11, optical detector 12, filters 13, 14 and rotating spindle 21 in Embodiment 1 twenty three. see image 3 . The temperature measuring device 23 can slide freely on the guide rail 24, and can measure the radial surface temperature of the film disc by sliding over different spray holes.

[0061] The process of real-time temperature measurement with the above device is:

[0062] 1) MOCVD equipment starts to perform epitaxial growth. The device of the present invention is in the working state of temperature measurement.

[0063] 2) The temperature measuring device 23 is located at a temperature measuring point, and the temperature at this measuring point is obtained by performing the steps of Embodiment 1 or Embodiment 2 to measure.

[0064] 3) The temperature measuring device 23 goes to other temperature measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com