Longitudinal flow capacity detecting method of plastic drainage board

A plastic drainage board and water flow technology, which is applied in the direction of detecting fluid flow by measuring pressure difference, measuring device, volume measurement, etc., can solve the problems of inability to measure the water flow of the drainage board, inaccurate test results, and affecting test results. Achieve the effects of reducing head loss, good sealing, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

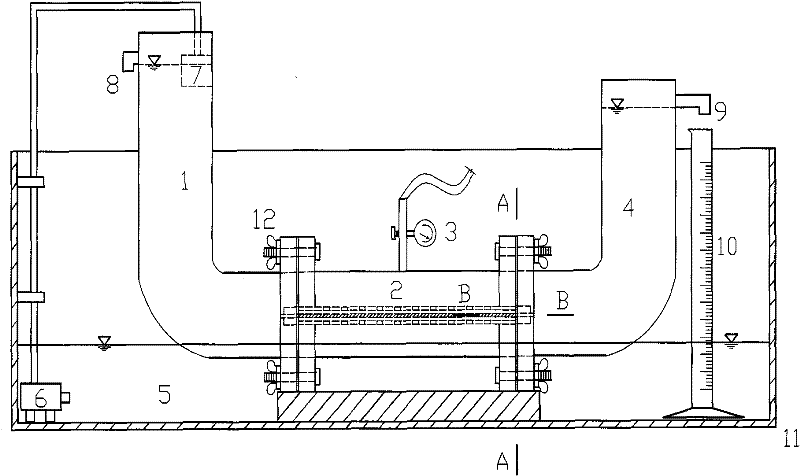

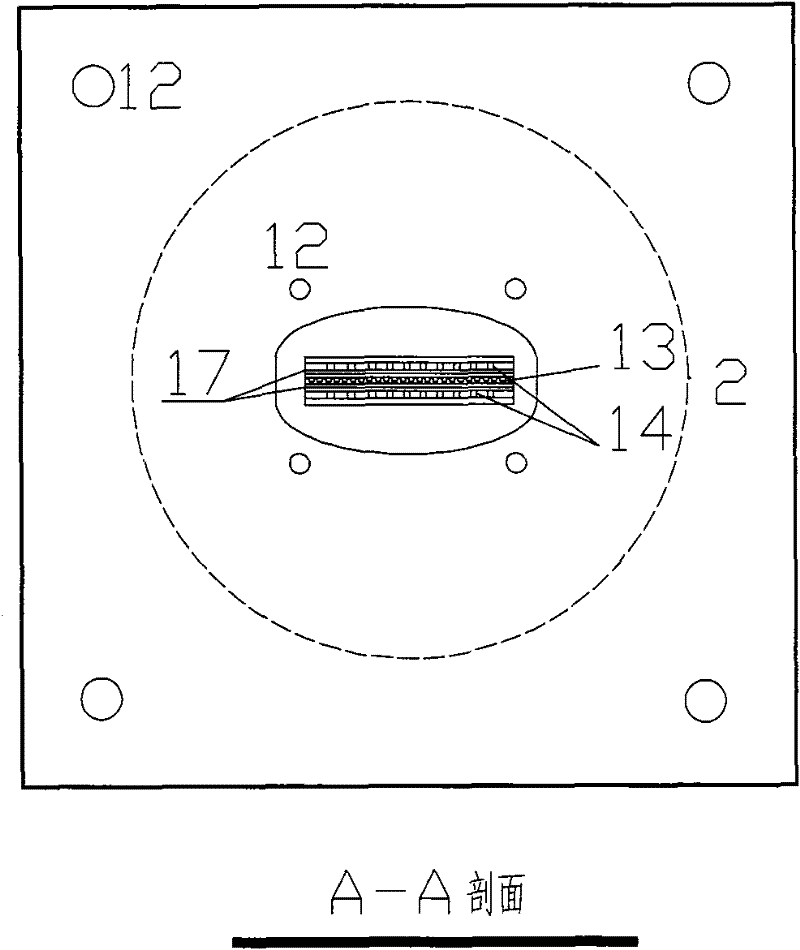

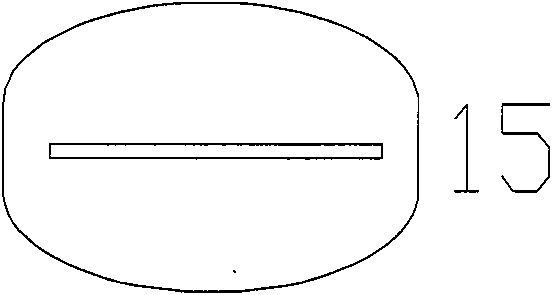

[0011] The present invention (see figure 1 ) using the upstream water level container 1, pressurized water container 2, pressure gauge 3, downstream water level container 4, circulating water pump 6 and box body 11, the pipe diameters of the upstream water level container, the downstream water level container and the pipe diameter of the pressurized water container Similarly, there is an elbow at the lower end of the upstream water level container and the downstream water level container, and the elbow ends of the upstream water level container and the downstream water level container have connecting plates connected with the connecting plates at the two ends of the pressurized water container respectively with bolts 12; After the 3 containers are connected into a "U" shape, they are placed upright in the box. The above-mentioned box is rectangular, and test water 5 is put into it, and a submersible pump is placed at the bottom of the box as a circulating water pump; the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com