Compatible mechanism for pumping liquid and exhausting air

A technology of motor teeth and motor gears, which is applied in the field of mechanisms compatible with liquid pumping and air pumping, can solve the problems of no self-priming, small adaptation range, and small output flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

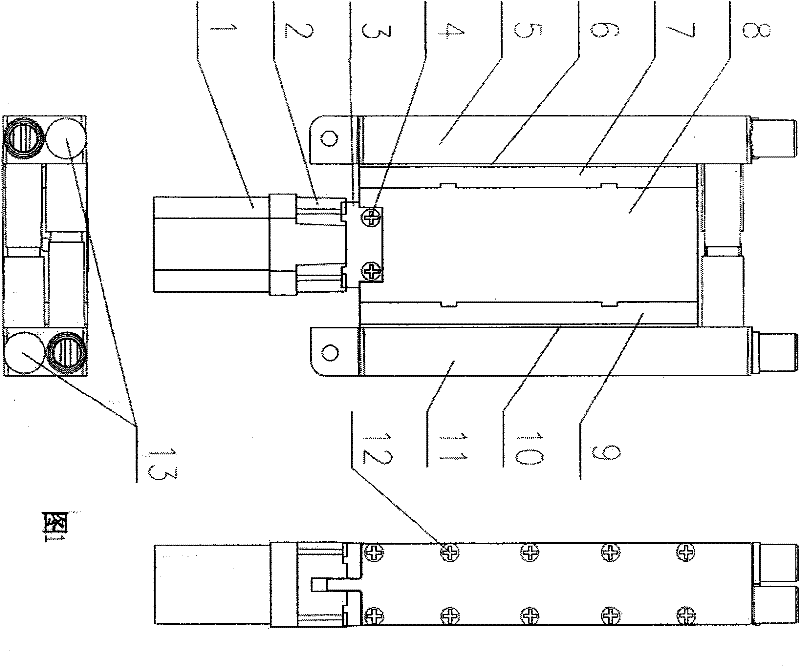

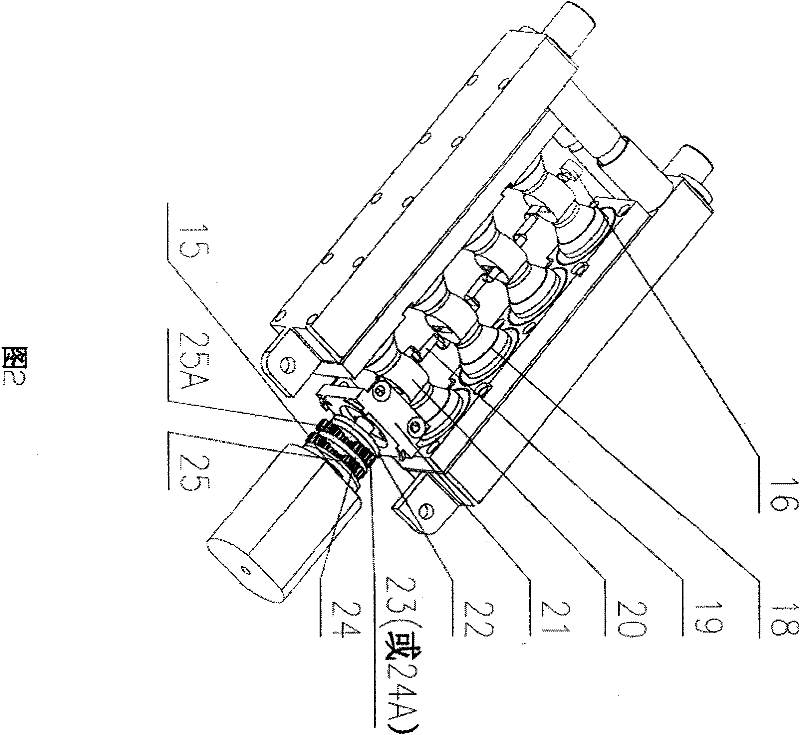

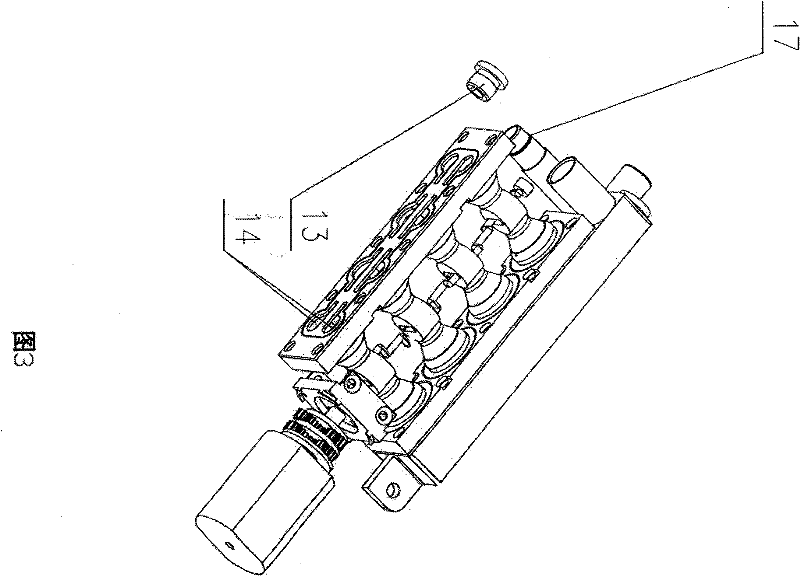

[0024] First example: see figure 1 , figure 2 , image 3 , Figure 4 ,

[0025] The present invention is made up of following parts:

[0026] Assembly and Connection Relationships:

[0027] The output shaft of the motor 1 is in interference connection with the motor gear 15, the motor gear 15 is in external mesh with the planetary gear 25, the planetary gear 25 is internally meshed with the outer ring gear 2, and there is a gap between the center hole of the planetary gear 25 and the planetary carrier 24. Cooperate, the central gear on the planetary carrier 24 and the next-stage planetary gear 25A are externally meshed, the next-stage planetary gear 25A is internally meshed with the outer ring gear 2, and the center hole of the next-stage planetary gear 25A is in contact with the next-stage planetary carrier 24A The clearance fit of the shafts above, and so on, can increase or decrease the number of stages of the planetary reducer under the same motor 1 to output differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com