Synchronous after flow ventilating compressor

A technology of air compressor and air flow channel, which is applied in the field of synchronous backflow ventilation compressor, and can solve the problems of unfavorable environmental protection, inability to save energy, low mechanical efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

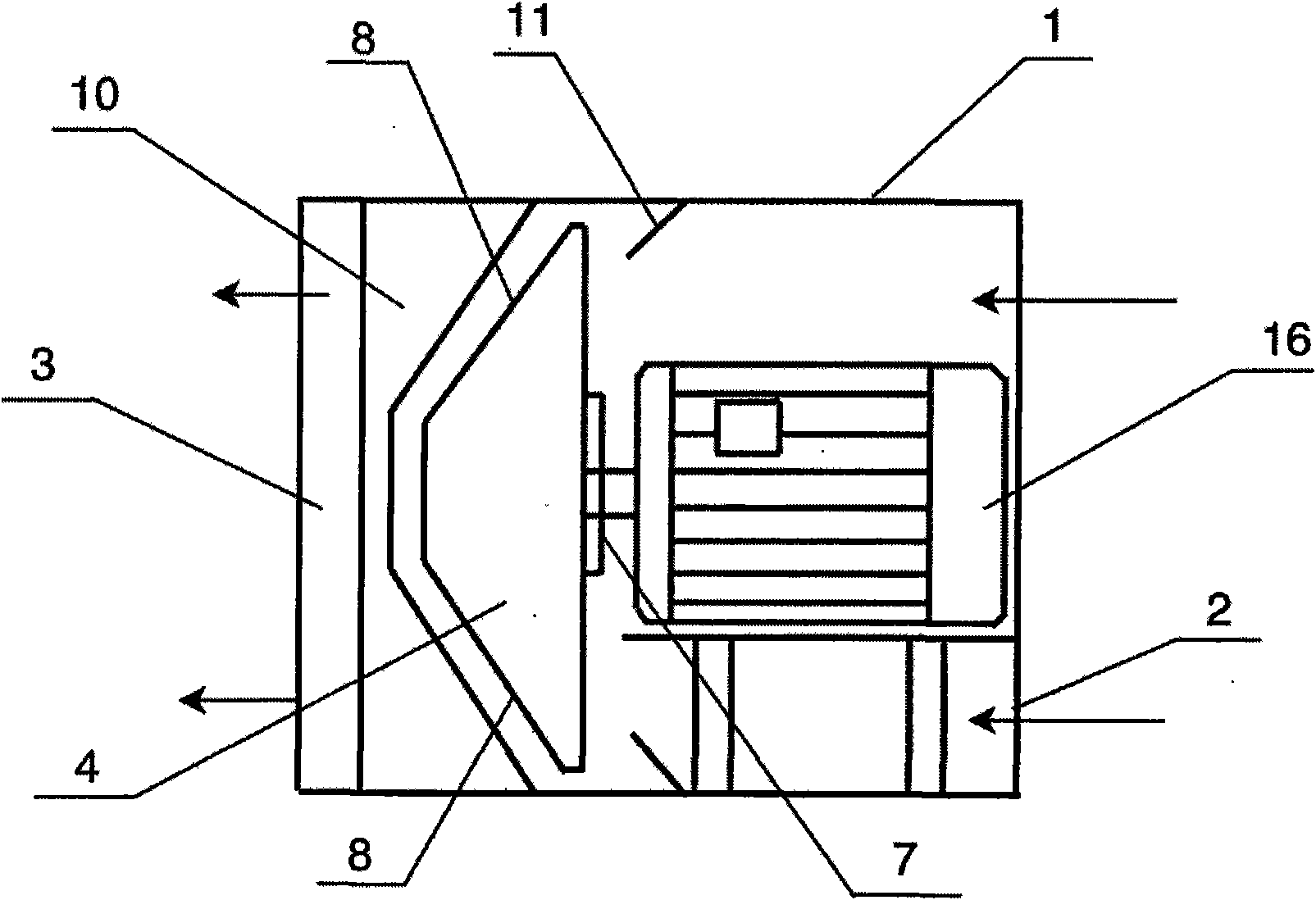

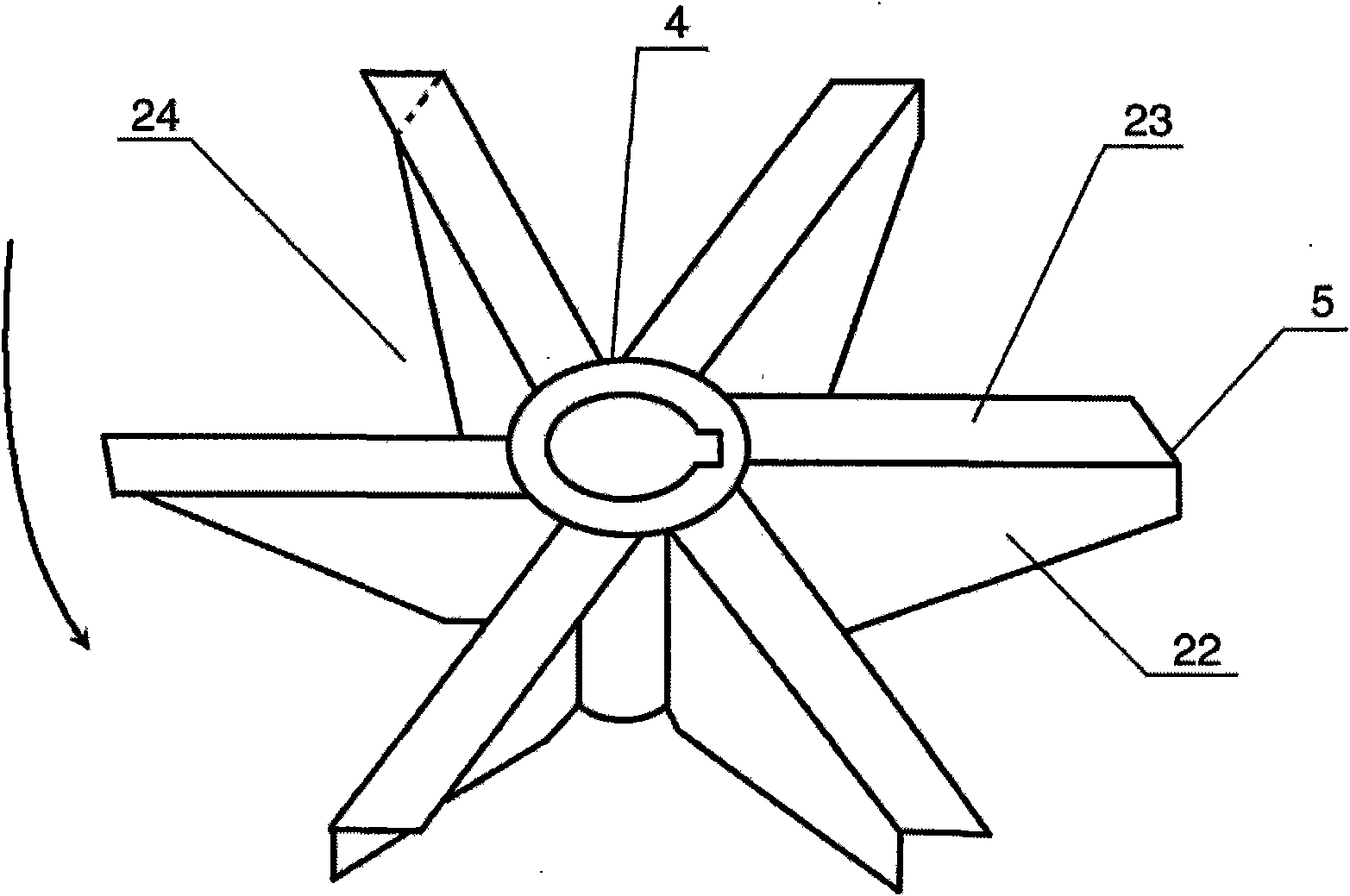

Embodiment 1

[0067] Embodiment 1 (with reference to figure 1 , figure 2 , image 3 ), a synchronous post-flow ventilation compressor, including a cylindrical shell structure 1, a casing air inlet 2, a casing air outlet 3, an impeller 4 made of double-walled impeller blades, and a double-walled impeller blade 5 (including a negative pressure Partition wall 23, thrust wall 22), impeller blade disc 7, the impeller blade 5 is not provided with a negative pressure partition wall on the axial rear side, and the axial front side is provided with a negative pressure partition wall 23, and the entire blade is radially from front to back along the impeller, From the rear of the shaft to the front of the shaft, it gradually inclines and shrinks and narrows. The rear axial side of the impeller becomes a high middle and low structure shape around the periphery. Air outlet 8. The casing axial outlet deflector 10 connected to the casing side wall is arranged outside the rear axial direction of the im...

Embodiment 2

[0071] Embodiment 2 (with reference to Figure 4 , figure 2 , image 3 ), a synchronous backflow ventilation compressor, this example is basically the same as Example 1, the difference is that this example is a unified rotor formed by connecting four impellers of the same structure in series with the same drive shaft, and the rotor is assembled in a cylindrical tube In the casing, the casing axial inlet deflector 29 is installed at the air inlet of the casing, the casing axial outlet deflector 10 is installed at the casing outlet, and the entire rotor is driven by the motor through the coupling 18 and the transmission shaft. 28 drive rotation; the second difference is that the front side of the impeller blade shaft of the four impellers in this example is inclined to the front of the impeller shaft, and the front shaft of the impeller is high around the middle depression on the side; the impeller blades are from front to back along the radial direction of the impeller Gradu...

Embodiment 3

[0075] Embodiment 3 (with reference to Figure 5 , Figure 6 , Figure 7 ), a synchronous backflow ventilation compressor, this example is basically the same as Example 1, the difference is that the casing of this example is a combination of cylindrical and spiral casings, that is, the front half is cylindrical, and two impellers are installed inside it , the second half is a spiral casing, and an impeller is installed inside it. The air outlet 3 of the casing is arranged on the radial edge of the spiral casing, and the outlet direction is radial; The outer side of the outlet end of the air inlet 2 of the shell is provided with a horn-shaped diffuser 20 that expands from front to back, and the outer side of the diffuser 20 is provided with a connecting deflector 21, and the diffuser 20 connects the deflector 21 with the air inlet 2 of the casing Inner wall connection. The second difference is that the impeller of this example is a synchronous backflow fan impeller, the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com