Selective plating method for aluminum material

A local electroplating and aluminum technology, which is applied in the direction of anodizing, coating liquid on the surface, pretreatment of the surface, etc., can solve the problems of high cost, excessive consumption of electroplating sources, and imprecise shielding or protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

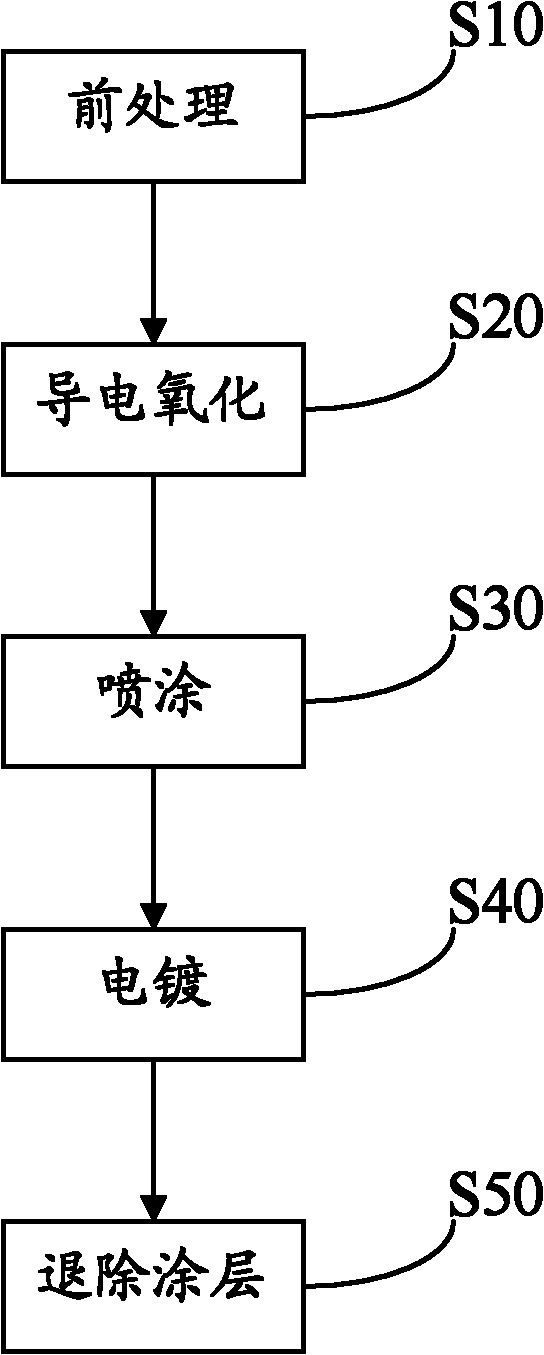

Method used

Image

Examples

Embodiment 1

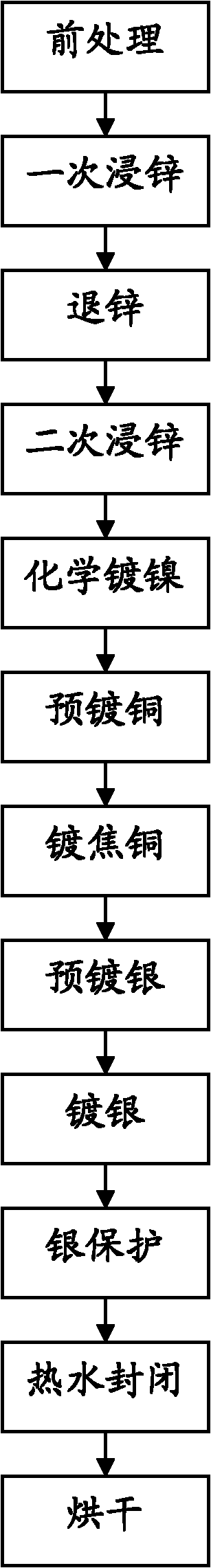

[0043]The surface of the aluminum material in this embodiment 1 is the surface of the radio frequency passive module made of aluminum alloy, and the local electroplating method on the surface of the radio frequency passive module includes the following specific procedures:

[0044] (1) The surface of the RF passive module is firstly processed by polishing and other machining, and then degreasing, cleaning and drying;

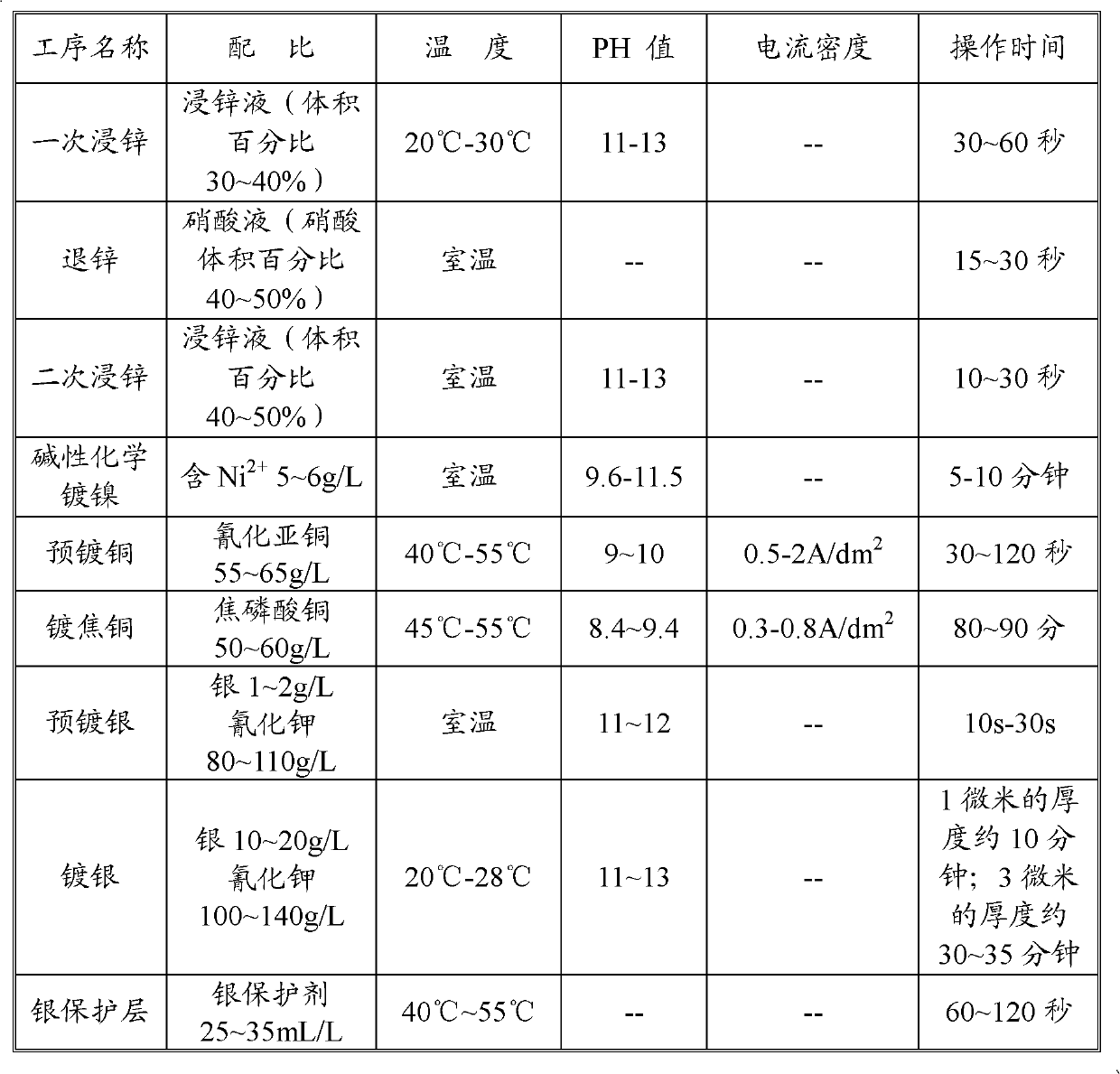

[0045] (2) get the trivalent chromate solution that mass concentration is 10%, wherein, the content of trivalent chromium in the trivalent chromate solution is represented by Cr 2 o 3 The measured content is about 2g / L, and then, at room temperature, treat the surface of the RF passive module with a trivalent chromate solution for about 3 minutes to form a conductive oxide layer in the non-plating area;

[0046] (3) At room temperature, spray it on the non-plating area according to the above coating formula to form a coating of about 40 microns, and let it dry ...

Embodiment 2

[0058] The surface of the aluminum material in this embodiment 2 is the surface of the radio frequency passive module made of aluminum alloy, and the local electroplating method on the surface of the radio frequency passive module includes the following specific procedures:

[0059] (1) with embodiment 1;

[0060] (2) get the trivalent chromate solution that mass concentration is 12%, wherein, the content of trivalent chromium in the trivalent chromate solution is represented by Cr 2 o 3 The measured content is about 2.2g / L, and then, at room temperature, treat the surface of the RF passive module with a trivalent chromate solution for about 2.5 minutes to form a conductive oxide layer in the non-plating area;

[0061] (3) At room temperature, spray it on the non-plating area according to the above coating formula to form a coating of about 50 microns, and let it dry naturally at room temperature for 8 minutes;

[0062] (4) At a temperature of 25°C, take a zinc dipping solut...

Embodiment 3

[0073] The surface of the aluminum material in this embodiment 3 is the surface of the radio frequency passive module made of aluminum alloy, and the local electroplating method on the surface of the radio frequency passive module includes the following specific procedures:

[0074] (1) with embodiment 1;

[0075] (2) get the trivalent chromate solution that mass concentration is 13%, wherein, the content of trivalent chromium in the trivalent chromate solution is represented by Cr 2 o 3 The measured content is about 2.5g / L, and then, at room temperature, treat the surface of the RF passive module with a trivalent chromate solution for about 2 minutes to form a conductive oxide layer in the non-plating area;

[0076] (3) At room temperature, spray it on the non-plating area according to the above coating formula to form a coating of about 60 microns, and let it dry naturally at room temperature for 10 minutes;

[0077] (4) At a temperature of 25°C, take a zinc dipping soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com