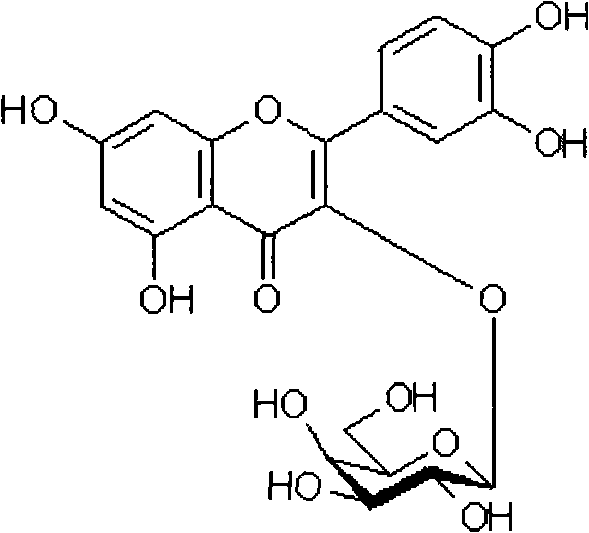

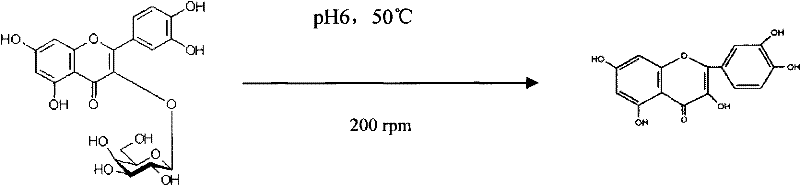

Method for transforming hyperin into quercetin by enzyme reaction

A technology of hyperin and quercetin, which is applied in directions such as fermentation, can solve problems such as low quercetin content and low yield, and achieves expansion of processability and practical application range, improvement of conversion rate, and improvement of pharmacological activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

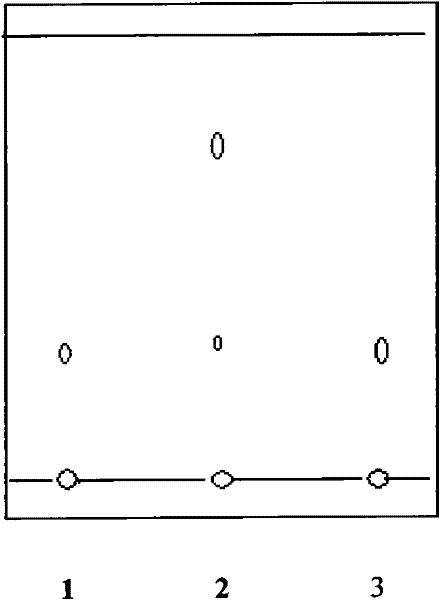

[0023] Example 1: In 1000mL Erlenmeyer flask, add 10mg hyperin standard substance and 400ml30% ethanol aqueous solution, adjust pH value to 6.0 with 1M NaOH solution, system reaches certain temperature 50 ℃, then add 0.5g naringinase (standard activity 475AGUPg), and finally, at 50° C. and 200 rpm, the reaction was stirred for 30 hours. Under the same conditions, no enzyme was added as the control group. After the reaction is finished, extract with the same volume of ethyl acetate to remove carbohydrates and enzyme protein impurities, and the extract is developed on a G silica gel plate (100mm × 25mm), with ethyl acetate: formic acid=25: 1 as the mobile phase. Observe under 365nm ultraviolet lamp and carry out qualitative analysis with TLC method, the result is as follows figure 1 Shown (1.R f金丝桃苷标准品 =0.36 2.R f反应产物 =0.90 3.R f对照组 =0.36), the reaction product R f The value 0.90 is much larger than the standard R f A value of 0.36 shows that quercetin with a polarity les...

example 2

[0026] Example 2: In the 1000ml Erlenmeyer flask, add 10mg hyperin standard substance and 400ml40% ethanol aqueous solution, adjust pH value to 5.0 with 1M NaOH solution, system reaches certain temperature 40 ℃, then add 0.5g naringinase (standard activity 475AGUPg), and finally, at 40° C. and 200 rpm, the reaction was stirred for 30 hours. Under the same conditions, no enzyme was added as the control group. After the reaction, extract with the same volume of ethyl acetate to remove carbohydrates and enzyme protein impurities. The extract is a G silica gel plate (100mm×25mm), ethyl acetate: formic acid: water=30:2:3 as mobile phase Expand, observe under 365nm ultraviolet light and carry out qualitative analysis with TLC method, the result is as shown in Figure 2 (1.R f金丝桃苷标准品 =0.44 2. R f反应产物 =0.923.R f对照组 = 0.44). Reaction product R f The value 0.92 is much larger than the standard R f A value of 0.44 indicates that quercetin, which is less polar than hyperin, has been ...

example 3

[0027] Example 3: In the 1000ml conical flask, add 10mg hyperin standard substance and 400ml 50% ethanol aqueous solution, adjust pH value to 6.0 with 1M NaOH solution, system reaches certain temperature 60 ℃, adds 0.5g naringinase (standard Activity 475AGUPg), finally, at 60°C and 200rpm, the reaction was stirred for 30 hours. Under the same conditions, no enzyme was added as the control group. After the reaction finishes, remove carbohydrates and enzyme protein impurities with ethyl acetate extraction of the same volume, the extract is developed with ethyl acetate: formic acid=25: 1 as the mobile phase, observe under a 365nm ultraviolet lamp and carry out qualitative analysis with TLC analysis, the result is as figure 1 Shown (1.R f金丝桃苷标准品 =0.36 2. R f反应产物 =0.90 3.R f对照组 =0.36), the reaction product R f The value 0.90 is much larger than the standard R f A value of 0.36 indicates that quercetin, which is less polar than hyperin, has been produced by the enzymatic reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com