Processing assistant for polyolefin granulation process, and preparation method and application thereof

A processing aid and polyolefin technology, which is applied in the field of processing aids and its preparation in the polyolefin granulation process, to achieve good viscosity reduction effect, enhanced internal lubrication, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

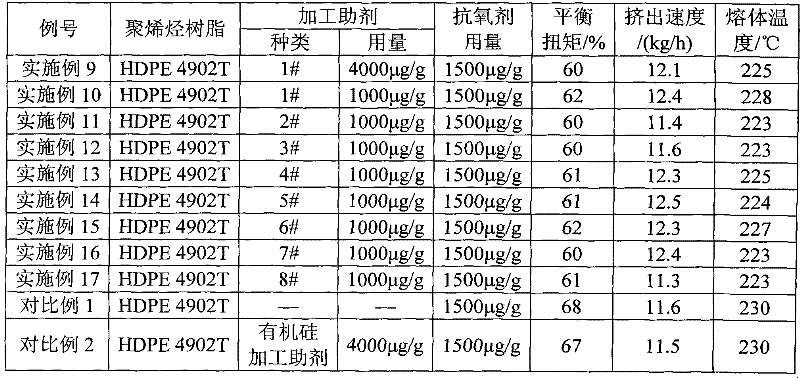

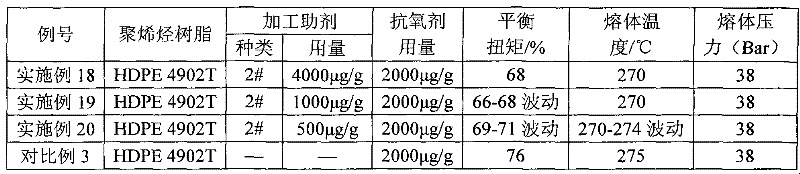

Examples

Embodiment 1

[0035] Heat 1000 g of polyethylene glycol 6000 to 80 °C. After the polyethylene glycol is melted, put 96 grams of phosphoric acid, 4 grams of antioxidant 1010, and 2 grams of auxiliary antioxidant 168. After stirring for 120 minutes, the product was taken out, cooled and ground to obtain a powdered processing aid. That is, processing aid 1#, the molar ratio of polyethylene glycol:phosphoric acid is 1:5.

Embodiment 2

[0037] Replace 96 grams of phosphoric acid with 2.6 grams of boric acid, and all the other conditions are the same as in Example 1. That is, processing aid 2#, the molar ratio of polyethylene glycol: boric acid is 1:0.25.

Embodiment 3

[0039]Heat 1000 g of polyethylene glycol 6000 to 80 °C. After polyethylene glycol is melted, put in 2.6 grams of boric acid, 500 grams of fumed silica, 4 grams of antioxidant 1010, and 2 grams of auxiliary antioxidant 168. After stirring for 120 minutes, the product is taken out, cooled and ground to obtain a powder processing aids. That is, processing aid 3#, the molar ratio of polyethylene glycol: boric acid is 1:0.25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size distribution | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com