Double-pole dry air or nitrogen insulated metal closed switch cabinet for high-speed railway

A technology of drying air and insulating metal, applied in the direction of switchgear, switchgear setting, electrical components, etc., can solve the problems of uneven electric field, inconvenient installation, affecting the working temperature in the cabinet, etc., to achieve uniform internal and external electric fields, Ease of fabrication and installation, and reduced risk of air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

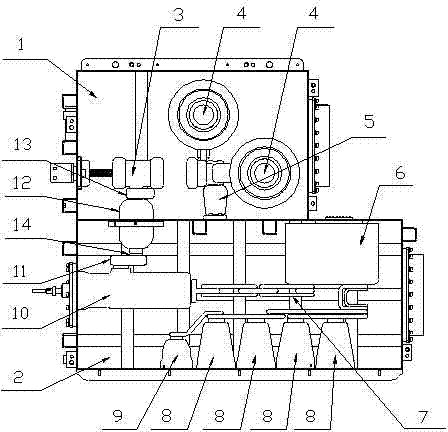

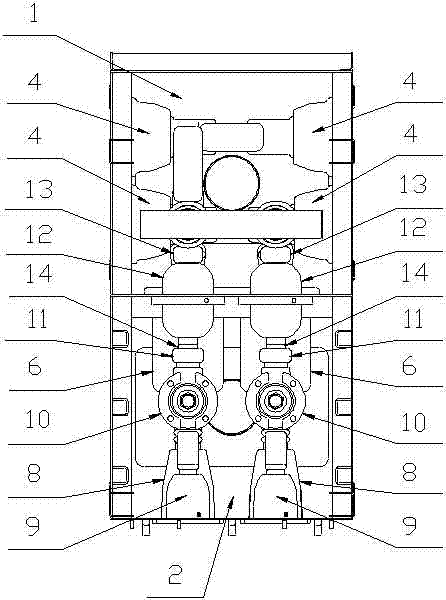

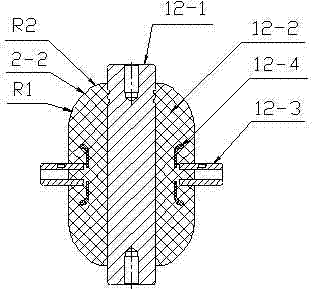

[0030] Such as figure 1 and figure 2 As shown, the present invention comprises a cabinet shell and a cabinet support, an upper air box 1 and a lower air box 2 are installed in the cabinet shell, and a three-position switch 3, a main bus bushing 4 and a three-position switch 3 are installed in the upper air box 1. Support insulator 5, built-in current transformer 6 and horizontal circuit breaker 10 are installed in lower gas box 2, plug-in type S3 is installed in lower gas box 2 and on the lower side of built-in current transformer 6 and horizontal circuit breaker 10 Cable bushing 8 and plug-in S2 bushing 9, between the built-in current transformer 6 and horizontal circuit breaker 10 and between built-in current transformer 6 and plug-in S3 cable bushing 8 and plug-in S2 The electrical connection between the bushings 9 is realized through the connecting row 7, the upper clip 13 is installed at the bottom of the intermediate conductor of the three-position switch 3 in the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com