Packaged cell

A battery and single cell technology, applied in the manufacture of secondary batteries, battery pack components, circuits, etc., can solve the problems of detrimental appearance, cost, labor and time, etc., so as to suppress the generation of pores and the appearance of bad appearance. , the effect of shortening cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0048] (Appearance structure of packaged battery 1)

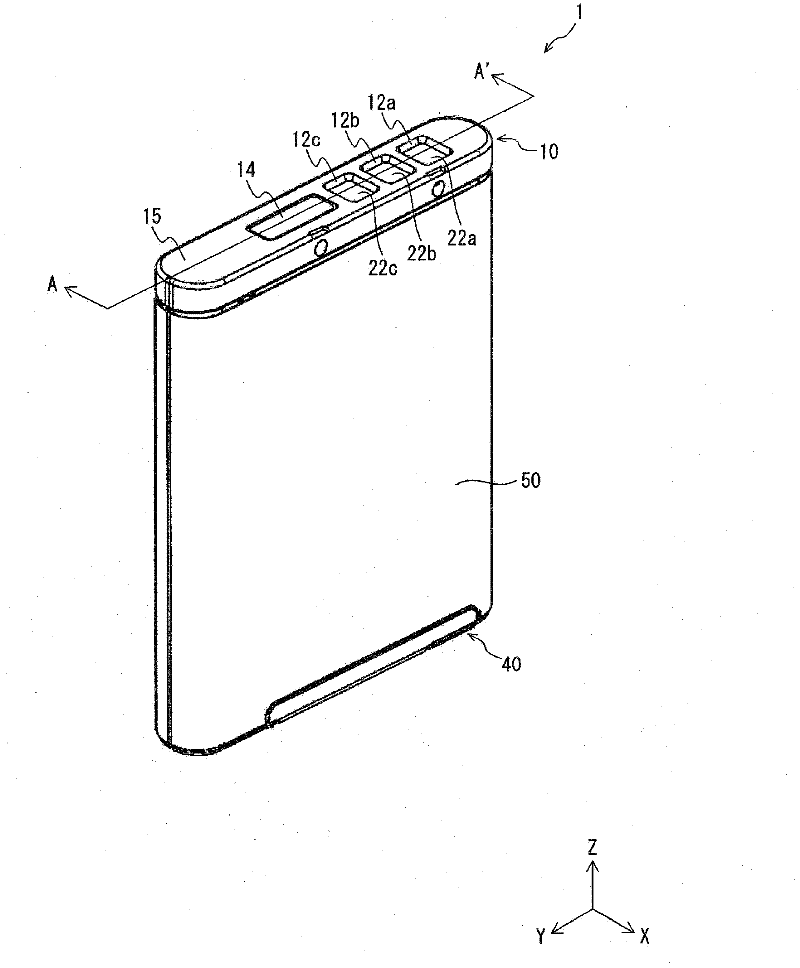

[0049] use figure 1 The appearance structure of the packaged battery 1 according to the embodiment will be described. figure 1 It is an external view of the packaged battery 1 .

[0050] like figure 1 As shown, the packaged battery 1 has a flat rectangular parallelepiped shape in which the X direction is the thickness direction, the Y direction is the width direction, and the Z direction is the height direction. The packaged battery 1 has a resin injection molding 10 made of low-temperature molding resin, an outer packaging label 50 covering the periphery and the bottom of the single cell 30 , and a bottom cover 40 covering the bottom of the single cell 30 .

[0051] External connection terminals 22 a , 22 b , and 22 c are exposed through terminal windows 12 a , 12 b , and 12 c arranged side by side on the surface of resin injection molding 10 on the upper portion of package battery 1 .

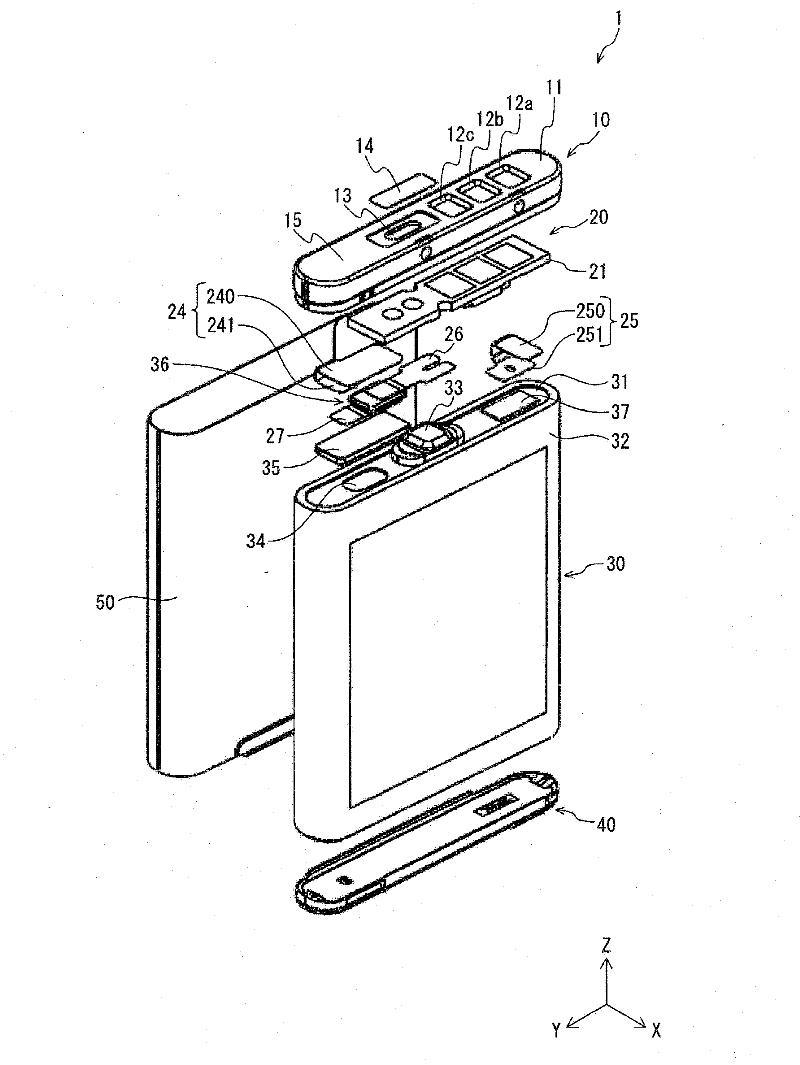

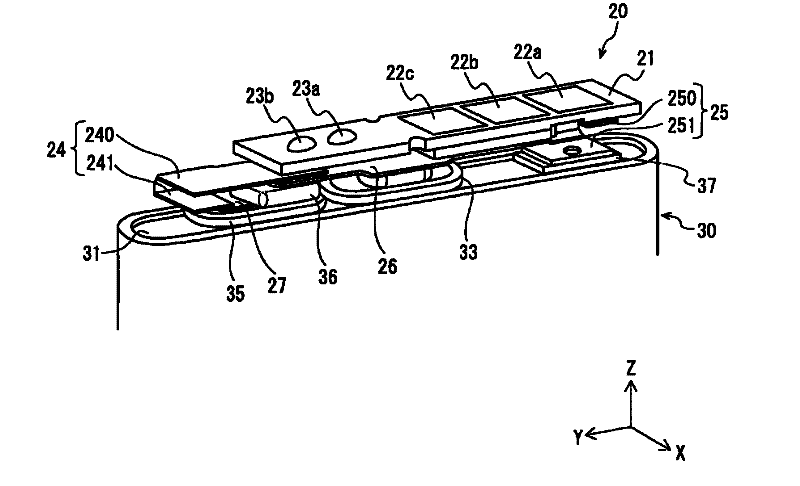

[0052] (Internal structure of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com