welding device

A welding device and welding current technology, applied in welding equipment, welding power source, resistance welding equipment and other directions, can solve the problem of large inductance, and achieve the effect of reducing inductance, size miniaturization, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]

[0051] Hereinafter, a welding torch 100 according to a first embodiment of the present invention will be described with reference to the drawings.

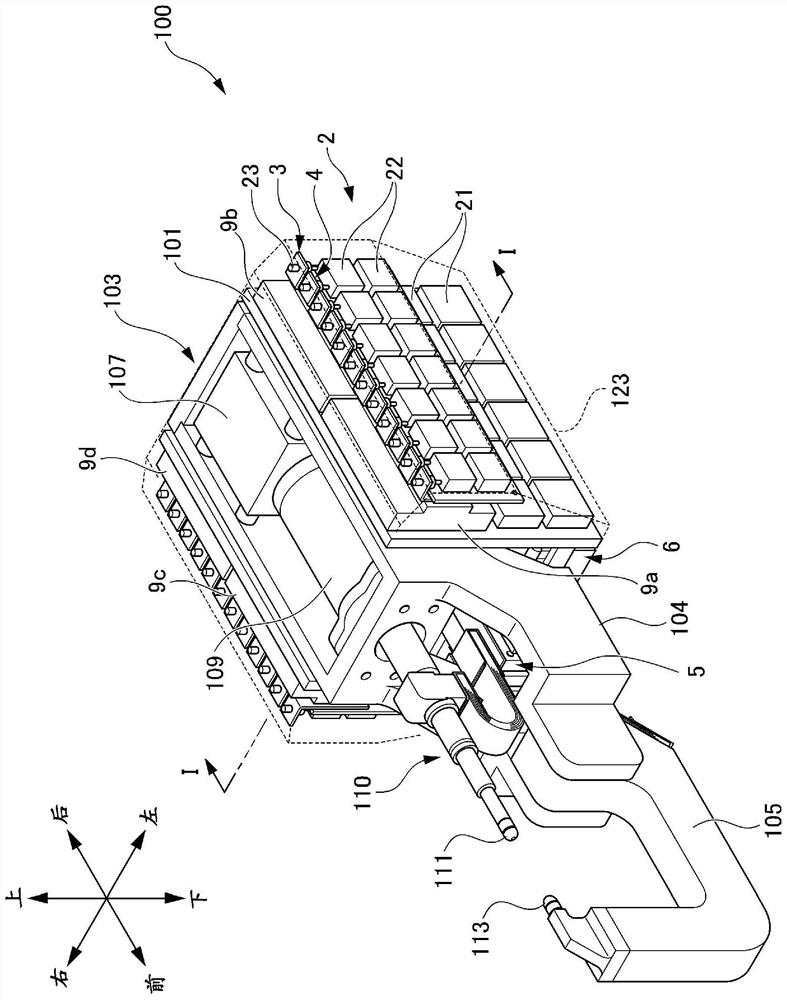

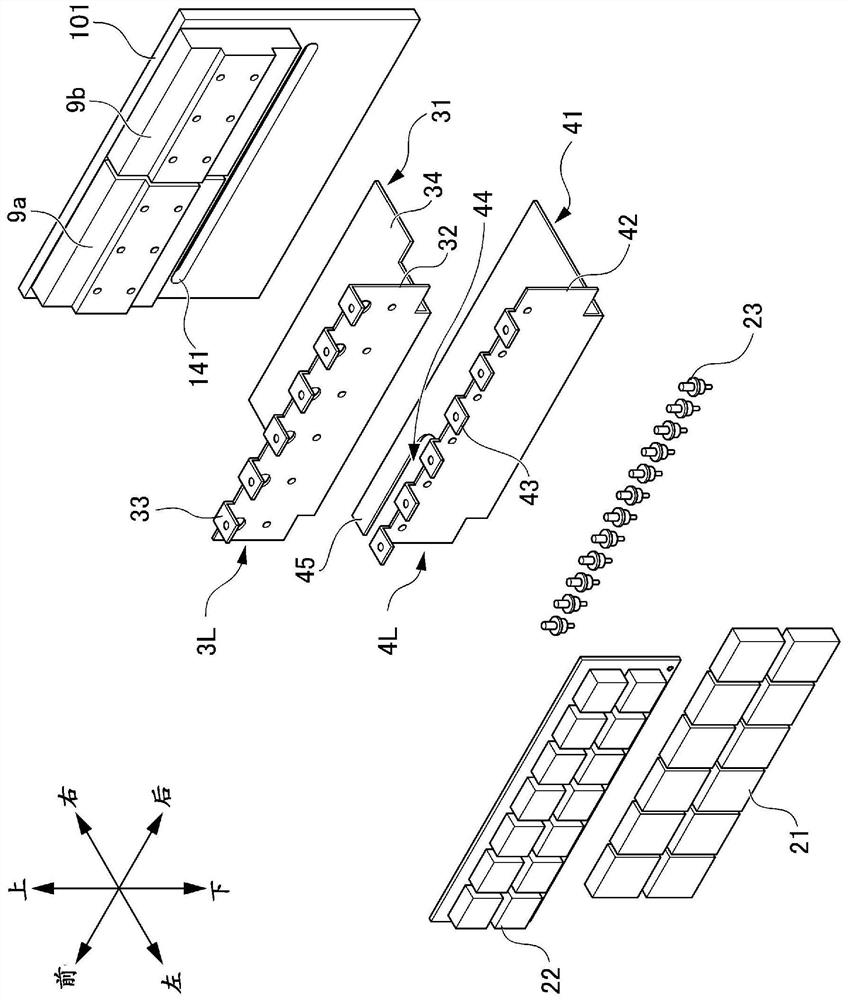

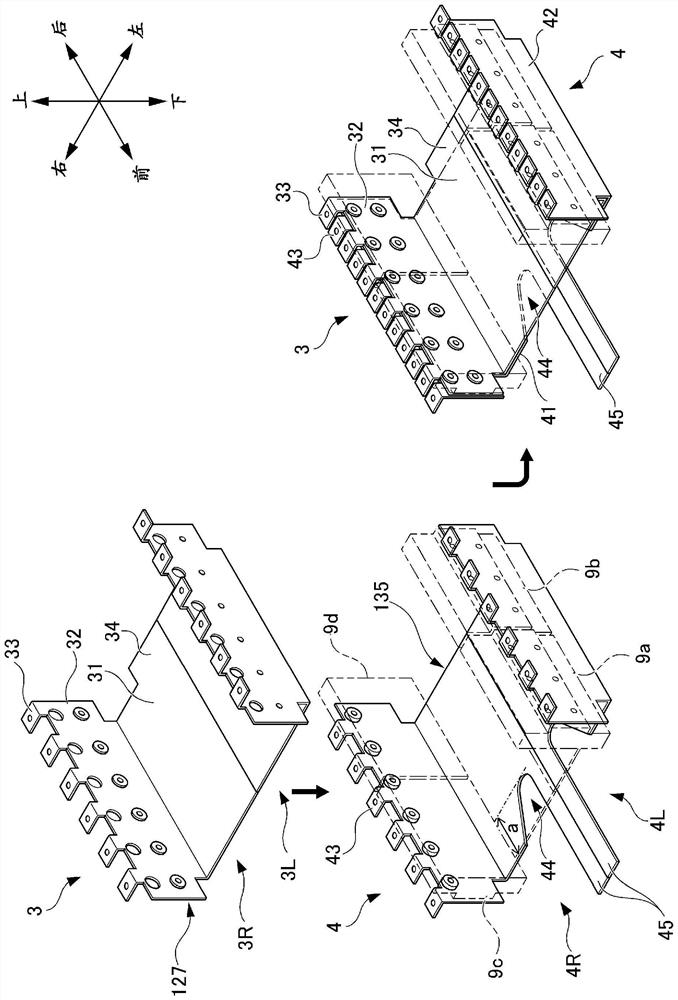

[0052] figure 1 It is a perspective view showing the whole welding torch 100 of this embodiment. Below, will figure 1 In the shown orthogonal coordinates, "front" is set to "front", "rear" is set to "rear", "upper" is set to "upper", "lower" is set to "below", and " Right" is set to "right direction", and "left" is set to "left direction". The main body 103 of the welding torch 100 has a frame 101 made of, for example, a metal material. An electronic substrate 107 and a cylinder 109 are housed in the main body 103 .

[0053] The structure of the welding torch 100 is bilaterally symmetrical with respect to the center line of the short side of the main body part 103 . An energy storage unit 6 , which will be described later as an electrical storage device, is stored in a lower portion of the main body 103 . Adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com