Array base plate, liquid crystal display and manufacturing method for array base plate

An array substrate and manufacturing method technology, applied in the field of liquid crystal display, can solve problems such as damage to TFT channels, achieve the effects of improving performance, improving production efficiency, and reducing the number of photolithography times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

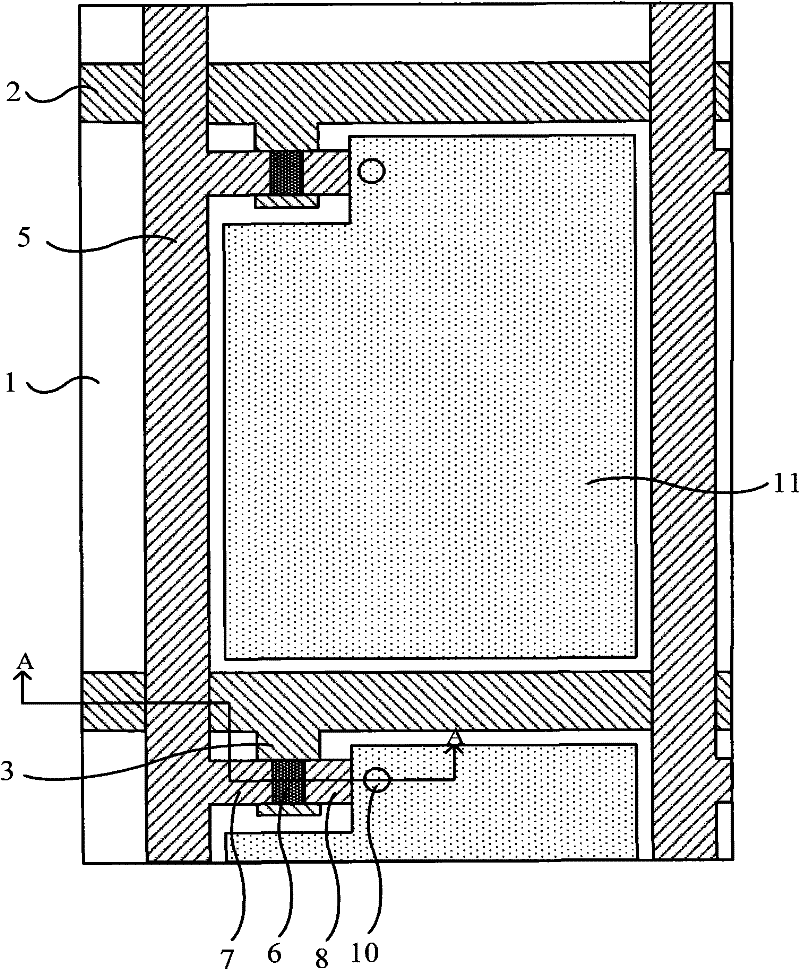

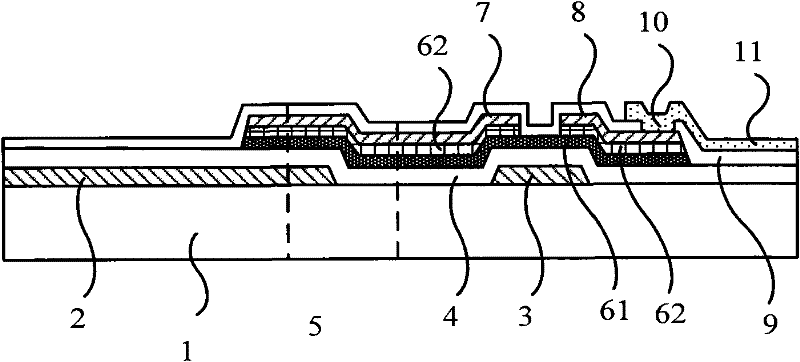

[0060] Figure 2A A partial top view structural schematic diagram of the array substrate provided by Embodiment 1 of the present invention; Figure 2B for Figure 2A Schematic diagram of the cut-away structure in side view along line A-A. Such as Figure 2A and Figure 2B As shown, the array substrate of this embodiment includes: a base substrate 1 on which gate lines 2, data lines 5, thin film transistors (TFT), pixel electrodes 11, active layer 6, and passivation layer 9 are formed. and gate insulating layer 4. Wherein, the TFT includes a gate electrode 3 , a source electrode 7 and a drain electrode 8 ; the gate electrode 3 is connected to the gate line 2 , the source electrode 7 is connected to the data line 5 , and the drain electrode 8 is connected to the pixel electrode 11 . Wherein, the gate insulating layer 4 is formed above the gate electrode 3; the active layer 6 is formed above the gate insulating layer 4; the passivation layer 9 is formed above the active laye...

Embodiment 2

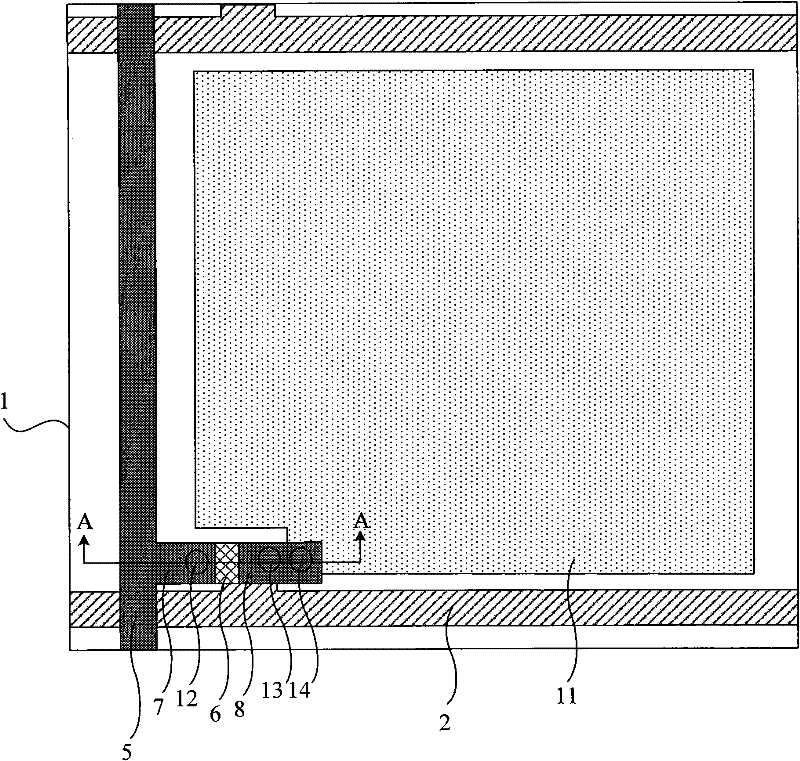

[0085] Figure 6A It is a flow chart of the manufacturing method of the array substrate provided by Embodiment 2 of the present invention. Such as Figure 6A As shown, the method of the present embodiment includes:

[0086] Step 61, depositing a transparent conductive film and a gate metal film on the base substrate, and forming a pattern including a pixel electrode, a gate electrode and a gate line through a patterning process;

[0087] Step 62, depositing a gate insulating layer film, an active layer film and a passivation layer film on the base substrate forming the above pattern, and forming a pattern including a passivation layer, an active layer and a gate insulating layer through a patterning process; wherein, the passivation layer The gate insulating layer includes a source electrode via hole and a drain electrode via hole; the gate insulating layer includes a contact via hole, and the contact via hole is located above the pixel electrode;

[0088] Step 63. Deposit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com