Method for manufacturing range hood and range hood

A technology for range hoods and manufacturing methods, which is applied in the direction of oil fume removal, heating methods, household heating, etc., and can solve the problems of easy accumulation of oil stains, time-consuming and laborious, easy accumulation of oil stains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific embodiments of the present invention are now described with reference to the accompanying drawings, in which the same reference numerals represent parts that are identical or similar in structure but identical in function. The bottom mentioned in this article refers to the end of the range hood that is close to the heat source after it is installed on a fixed object, and the top refers to the end away from the heat source.

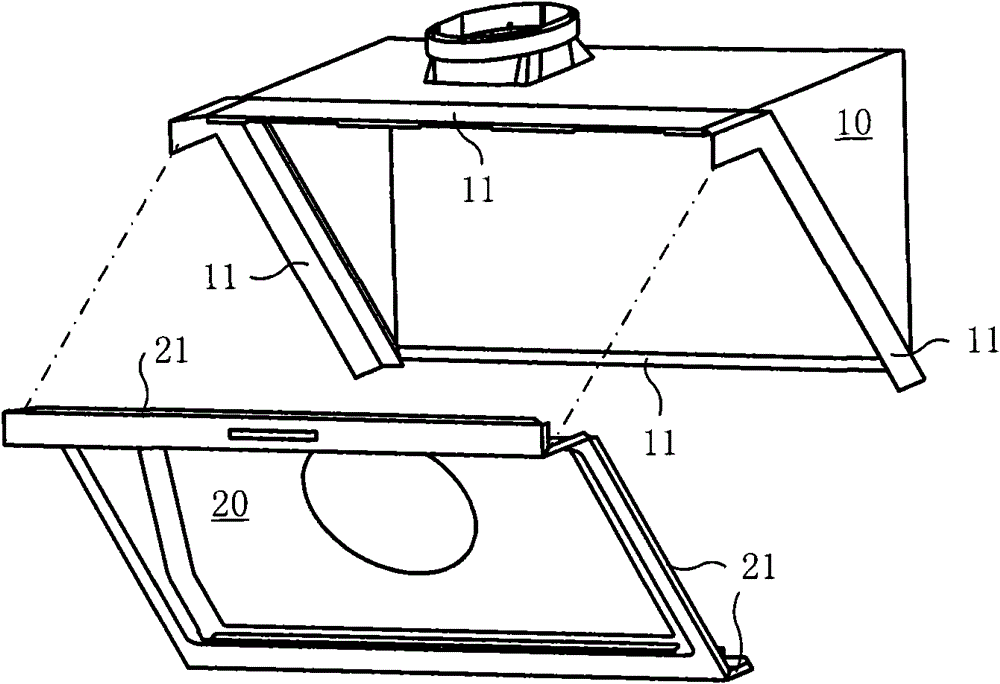

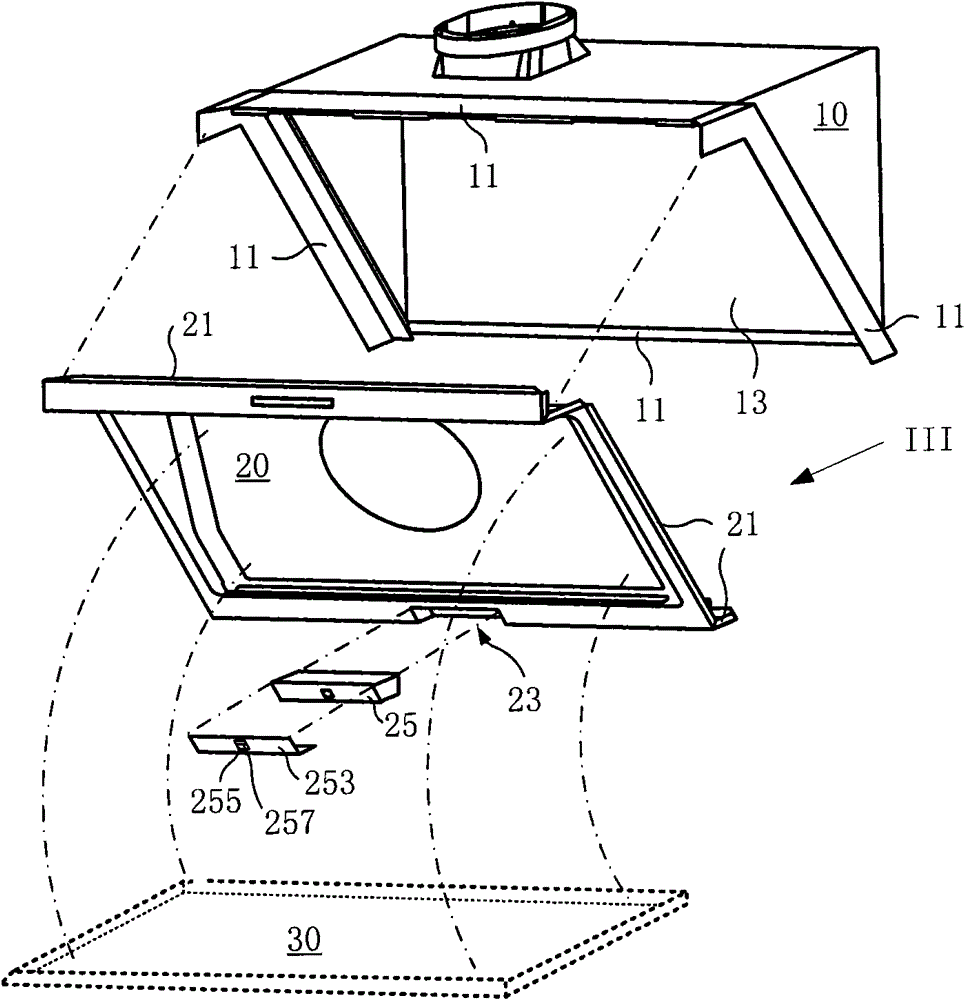

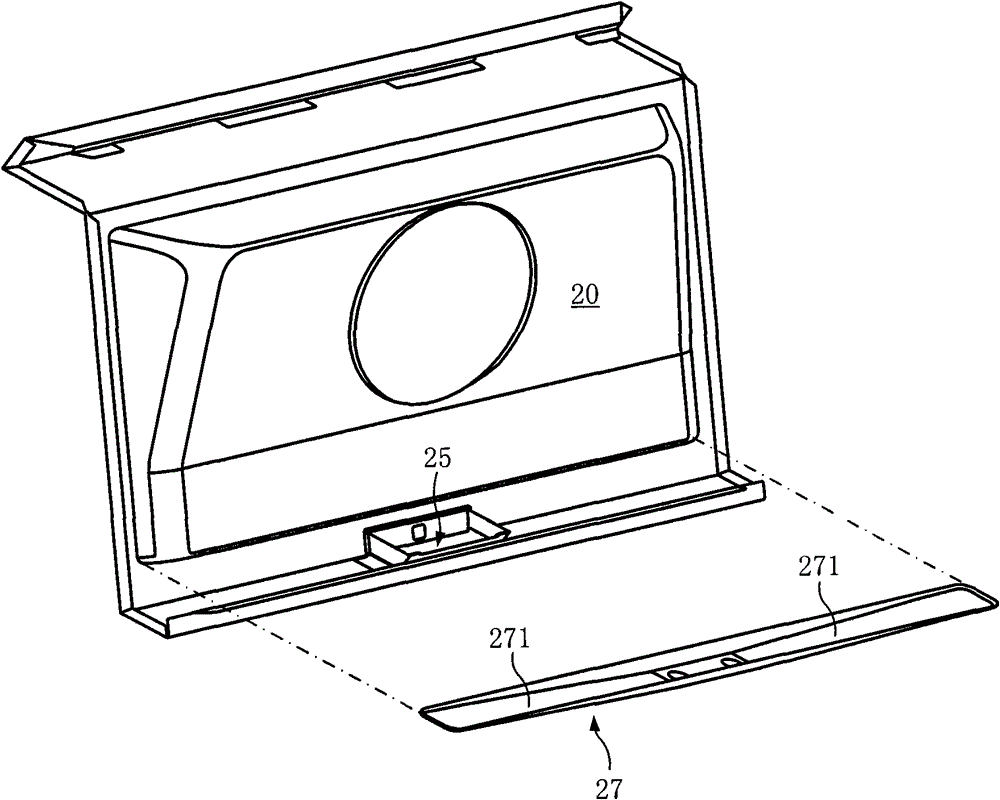

[0031] figure 1 It is a structural schematic diagram of a side-suction range hood, which includes a fume collecting hood 20 and a casing 10 . The fume collecting hood 20 is integrally formed by a plate, and there is a fume collecting hood frame 21 around it. There is a casing frame 11 around the casing 10 . During manufacture, the frame 21 of the smoke collecting hood and the frame 11 of the shell are first welded together so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com