Running mechanism for guitar coating

A technology for operating mechanism and guitar, which is applied to devices and coatings that apply liquid to the surface, which can solve the problems of increased post-process operations, poor oil accumulation on the guitar, and long injection and leveling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

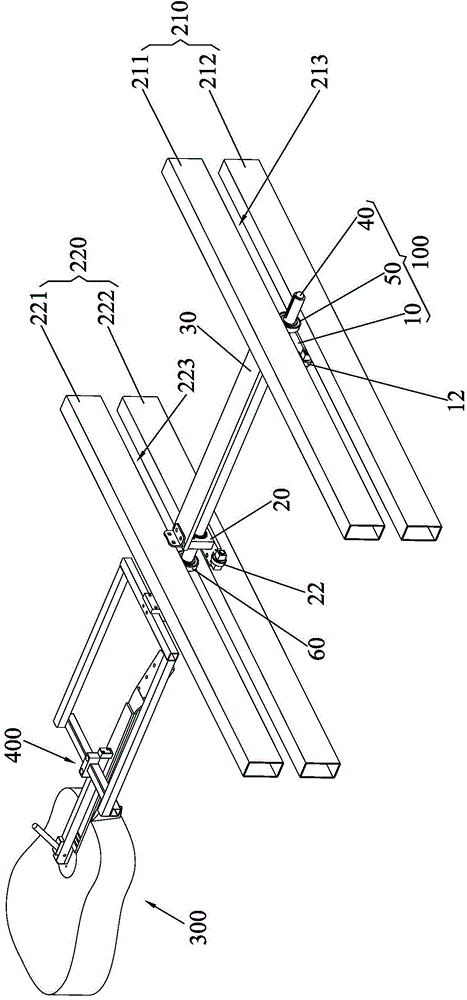

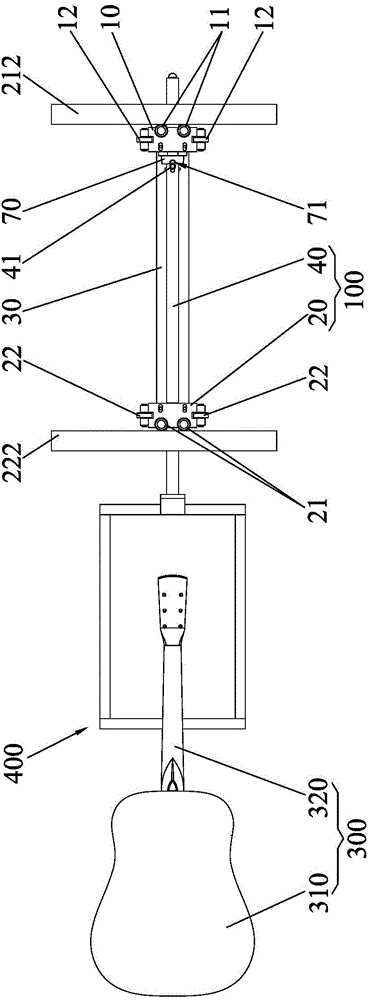

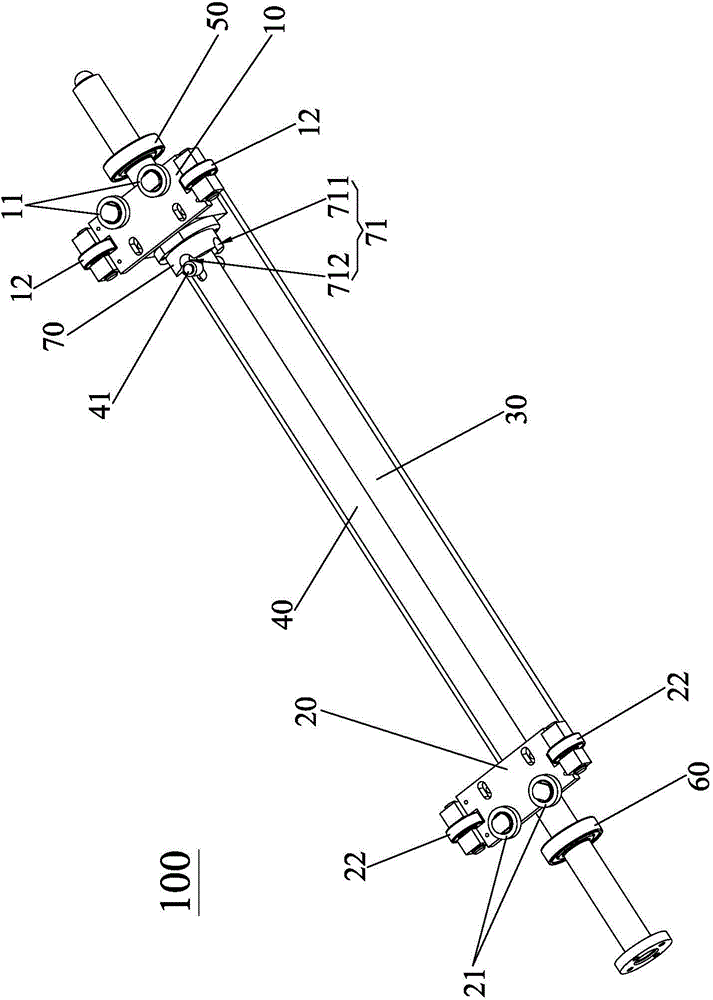

[0027] see Figure 1 to Figure 3 , the running mechanism 100 for guitar painting of the present invention is suitable for sliding the clamp 400 clamped with the guitar frame 300 in horizontal translation under the guidance of the guide rail. Such as figure 1 and figure 2As shown, the guide rails include a first guide rail 210 and a second guide rail 220 that are parallel to each other and spaced apart along the horizontal direction. The guide rail 210 and the second guide rail 220 are guided along the front-rear direction of the horizontal plane to provide guidance for the movement of the fixture 400 along the front-rear direction of the horizontal plane, and the first guide rail 210 and the second guide rail 220 both include upper guide rails that are paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com