Quick polishing grinder

A polishing and fast technology, applied in grinding machines, belt grinders, grinding/polishing equipment, etc., can solve the problems of low work efficiency and difficult to control operating pressure, and achieve high production efficiency, easy control, and large production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

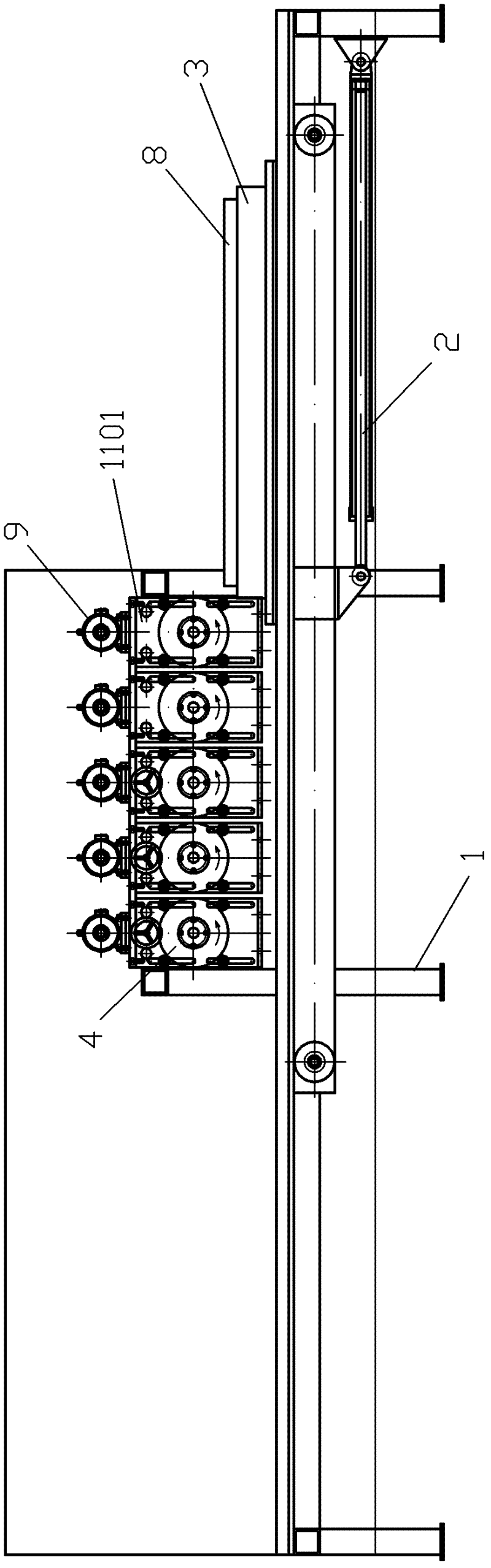

[0024] refer to Figure 1-Figure 4 , The rapid polishing grinder of the present invention includes a frame 1, a magnetic work surface 3, a clamping mechanism 11, an integral lifting mechanism 5 and a traveling mechanism 2. The magnetic working surface 3 is placed on the traveling mechanism 2 and can move back and forth horizontally with the traveling mechanism 20; the traveling mechanism 2 is a hydraulic structure.

[0025] The clamping mechanism 11 is arranged on the overall lifting mechanism 5 and is located above the magnetic worktable 3. The clamping mechanism 11 includes five clamps 1101, and each clamp 1101 contains All are provided with a grinding roller 4. In this embodiment, the meshes of the abrasive belts of the five grinding rollers 4 are 60 mesh, 80 mesh, 120 mesh, 240 mesh and 320 mesh respectively. The grinding rollers 4 are driven by a motor 7, and one motor drives all the grinding rollers 4, or each grinding roller 4 is driven by a motor. In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com