Bracket for grating plate of sieve basket at filter section of settling filtering centrifuging machine

The technology of a centrifuge and a filter section is applied in the field of a screen basket grid plate bracket of a filter section of a sedimentation filter centrifuge, which can solve the problems of restricting the solid-liquid separation effect, small opening area of the bracket, and reduced work efficiency, etc. Solid-liquid separation effect, large opening area, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

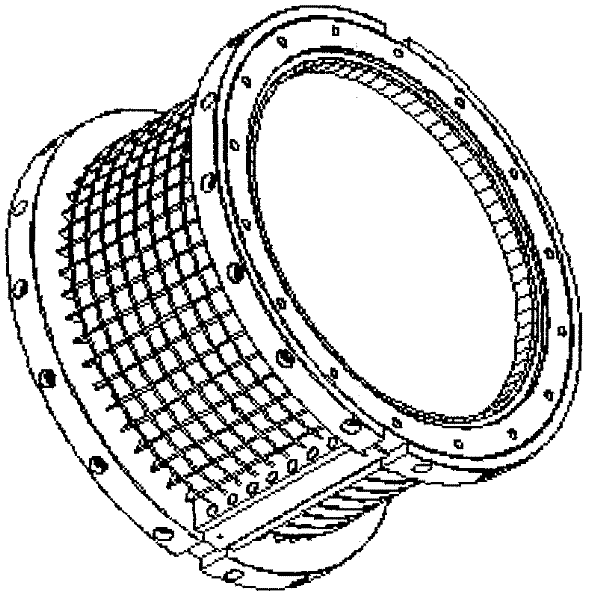

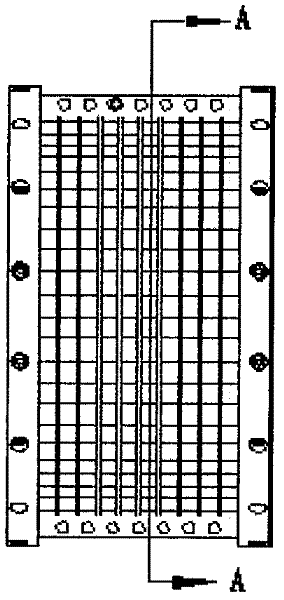

[0010] A settling filter centrifuge filter section sieve basket grid plate bracket, which includes a left half screen 2, a right half screen 3, a left half sieve basket 1, a right half sieve basket 4 and a sieve basket bracket 5, the The sieve basket bracket 5 is an integral sieve basket bracket formed by connecting two flanges through two sieve basket pillars. The left half sieve basket 1 is provided with the left half screen 2, and the right half sieve basket 4 is provided with In the right half screen 3, the screen basket bracket 5 connects the left half screen basket 1 and the right half screen basket 4 through bolts to form a cylindrical screen basket. The half screen 2 and the right half screen 3 are evenly provided with strip-shaped water-permeable holes, and water flows out through the strip-shaped water-permeable holes on the screen.

[0011] Due to the increased opening ratio, when the sediment passes through the filter section, under the action of centrifugal force,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com