Laboratory hydraulic system

A hydraulic system, laboratory technology, applied in the direction of laboratory stools/laboratory benches, educational appliances, instruments, etc., can solve the problem of no teaching needs students' course experiments, etc., to achieve the effect of complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

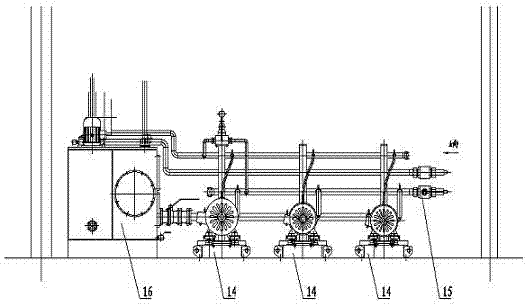

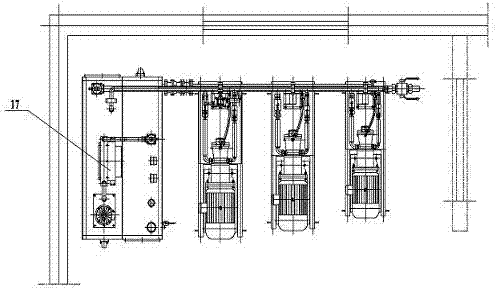

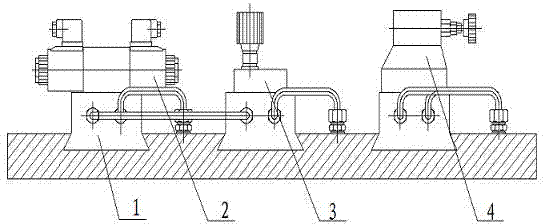

[0013] Such as Figure 1-Figure 5 As shown, the laboratory hydraulic system consists of two parts: a test bench and a power source. The test bench includes a plate valve test bench, a superimposed valve test bench and a cartridge valve test bench. The plate valve test bench mainly consists of a socket bottom plate 1, an electromagnetic The reversing valve 2, the plate type throttle valve 3 and the plate type overflow valve 4 are composed. The electromagnetic reversing valve 2, the plate type throttle valve 3 and the plate type overflow valve 4 are respectively set on the socket type bottom plate 1. The superposition valve test bench mainly It is composed of a socket type passage body 5, a superposition type overflow valve 6, a superposition type throttle valve 7 and an electromagnetic directional valve 8. The superposition type overflow valve 7 is arranged on the socket type passage body 5, and the superposition type throttle valve 7 is set on the superimposed relief valve 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com