Production of microbiological feed additive and enzyme preparation by solid fermentation of Uygur medicine (ethno-medicine) residue

A technology of microbial feed and solid-state fermentation, which is applied in animal feed, animal feed, application, etc., can solve problems such as large amount of use affecting the effect of compound feed, failure to play a role, environmental pollution, etc., to improve palatability and utilization rate, Effects of improving productivity and reducing bacterial contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

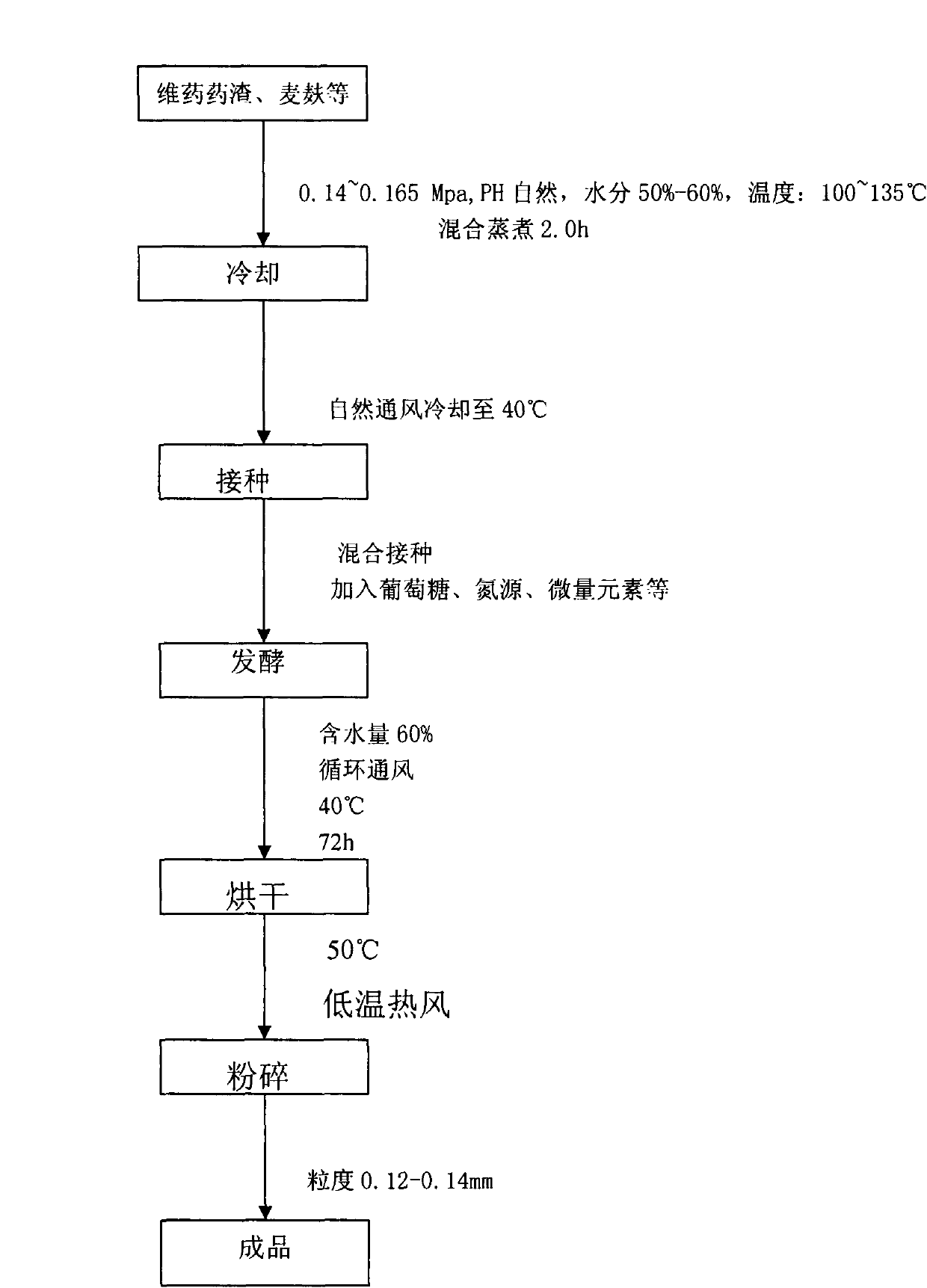

Method used

Image

Examples

Embodiment 1

[0017] Solid-state fermentation of Uighur medicine (ethnic medicine) "Zukamu" dregs to produce compound microbial additives

[0018] The ratio of "Zukamu" medicinal residue and wheat bran is 3:7, add 1% glucose, mix and adjust the water content to 50%-60%, steam pressure: 0.14-0.165Mpa, temperature: 100-135°C, cooking time is For two hours, cool to 40°C, insert the strains (two parts of Aspergillus oryzae, one part of Bacillus subtilis) and mix them into the fermentation tank, spread 20-40cm thick on the fermentation bed, the temperature is 40-42°C, the initial pH value, keep The water content is 50%-60%, fermented with circulating ventilation, and the fermentation period is 72 hours. It is obtained by drying at low temperature (40-60°C) and pulverized. Quality requirements: the content of prebiotics is not less than 1.5×10 9 / g, the acid protease activity is not less than 5000U / g, the total alkaloid content is not less than 0.03%, and the addition amount in the feed is 0.2%. ...

Embodiment 2

[0020] Uighur medicine (ethnic medicine) "Hanchuan Zupa" solid-state fermentation to produce compound microbial additives

[0021] "Hanchuan Zupa" medicine dregs, soybean meal, wheat bran, rice husk powder in a ratio of 3:1:3:3, add 1% corn starch, mix and adjust the water content to 50%-60%, steam pressure: 0.14-0.165 Mpa, temperature: 100~135°C, cooking time is two hours, cooled to 40°C, insert strains (2 parts of Bacillus subtilis, 1 part of plant Lactobacillus, 1 part of Saccharomyces cerevisiae, 1 part of lactic acid tablet Bacteria,) mixed and moved to the fermentation tank, spread 30-60cm thick, water content 60%-65%, anaerobic fermentation, fermentation cycle is 7 days, after low-temperature drying (40-60 ℃) pulverization vestige, quality requirements: The content of probiotics is not less than 2.0×10 9 / g, the organic acid content shall not be less than 0.3%, and the addition amount in the feed is 0.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com