PWM (Pulse-Width Modulation) controller

A controller and comparator technology, applied in the power supply field, can solve the problems of increasing system complexity, limiting the application environment, current mode peak current limit drift, etc., to ensure the current limit, improve efficiency, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

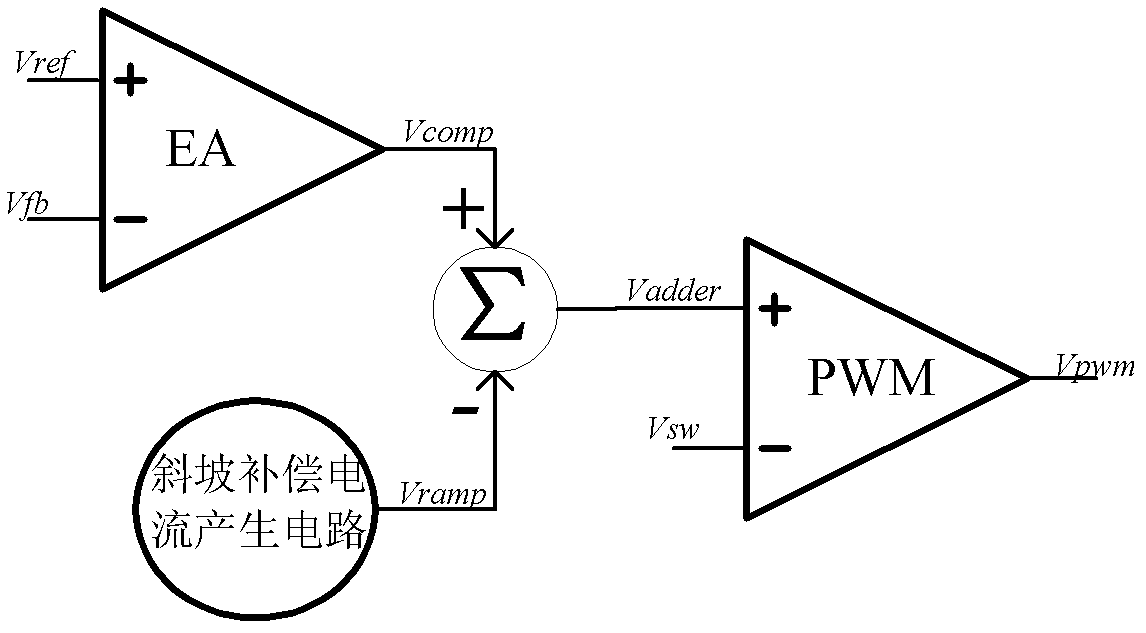

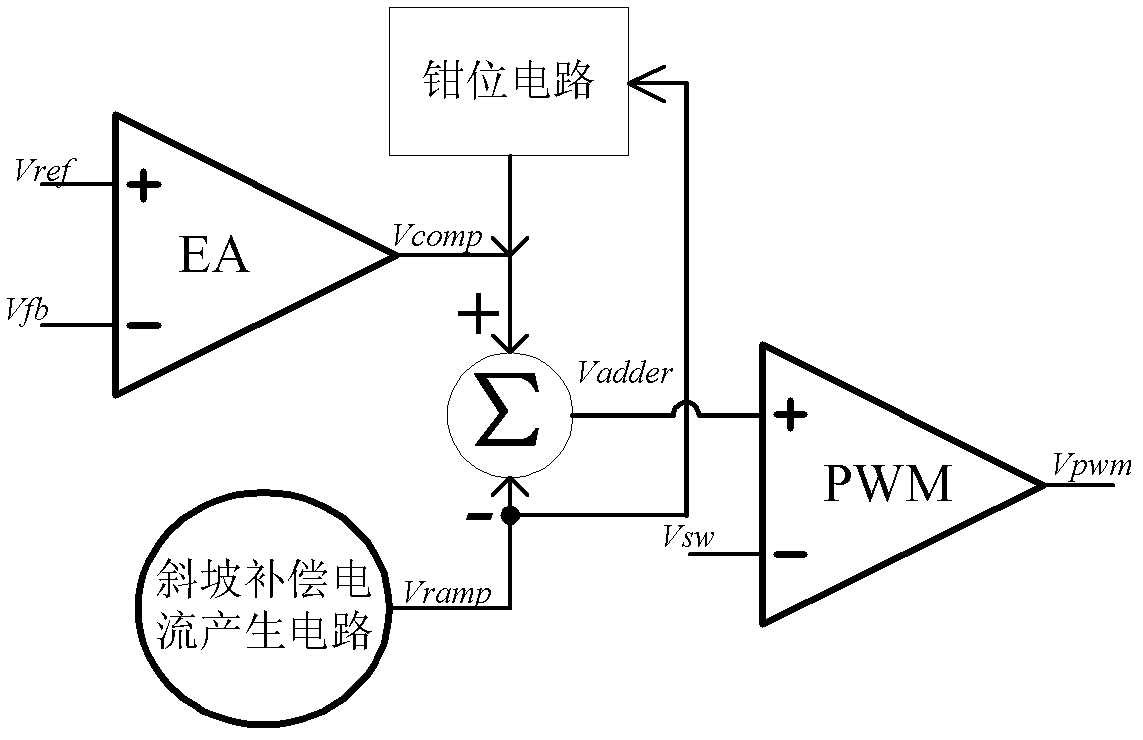

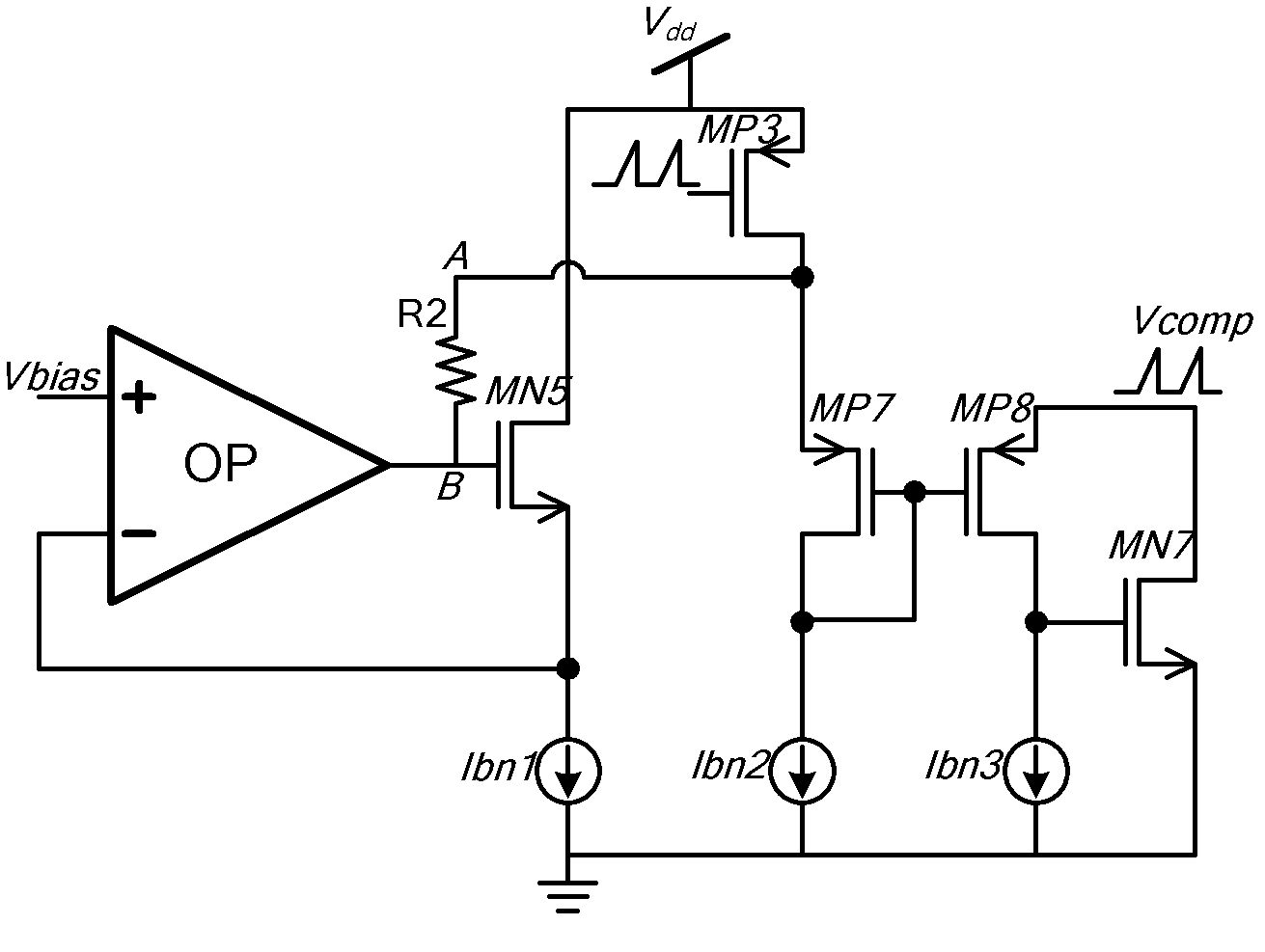

[0024] The structure schematic diagram of PWM controller of the present invention is as figure 2 As shown, it includes an error amplifier EA, a PWM comparator, a slope compensation current generation circuit, a clamp circuit and a slope compensation superposition circuit, wherein the slope compensation current generation circuit is used to convert the slope compensation voltage into a slope compensation current, The positive input terminal of the error amplifier EA is used to input and output the feedback voltage V fb , the negative input terminal is used to input the external reference voltage source V ref ; The clamping circuit is used to make the signal output by the error amplifier follow the slope compensation voltage to change with the same slope, and its input terminal is connected to the output terminal of the slope compensation curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com