Data acquisition and information management system and acquisition method for production line

An information management system, production line data technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of labor consumption and high error rate, and achieve the effect of simple structure, improved adaptability, and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

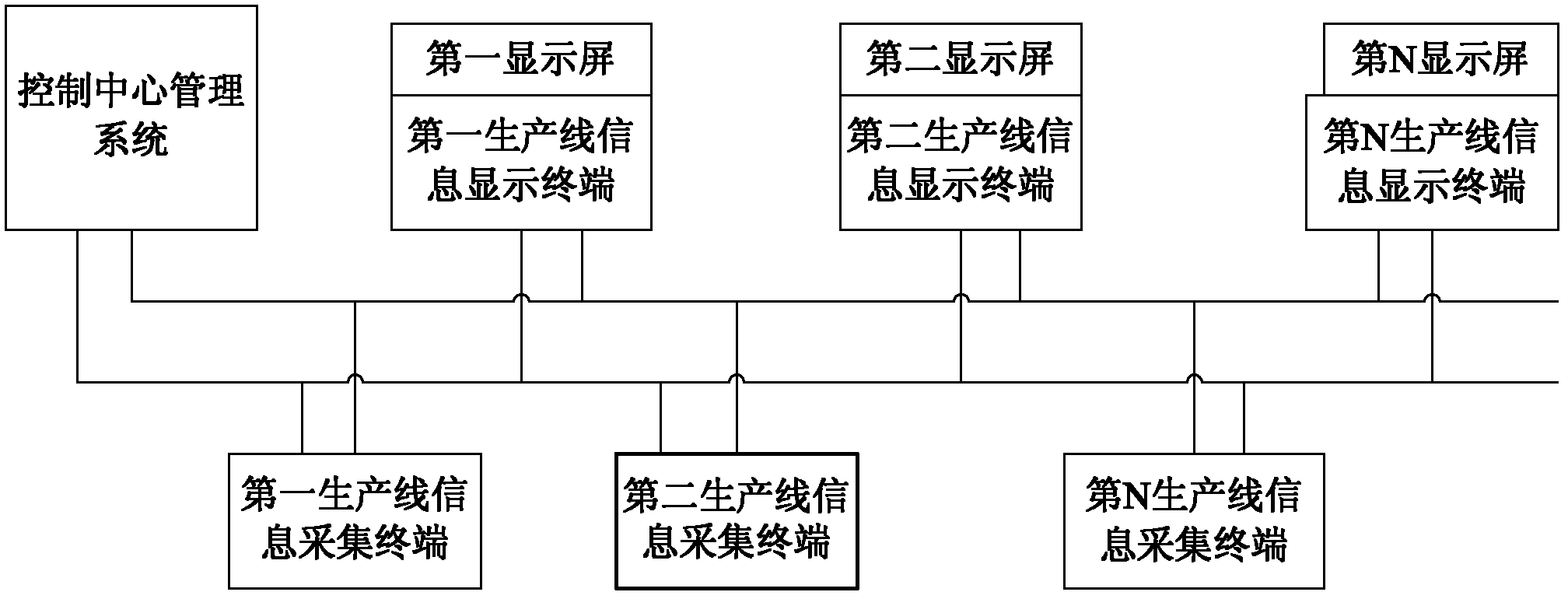

[0033] Such as figure 1 Shown, production line data collection and information management system of the present invention is the production line data collection and information management system based on single-chip microcomputer and computer technology, and it comprises:

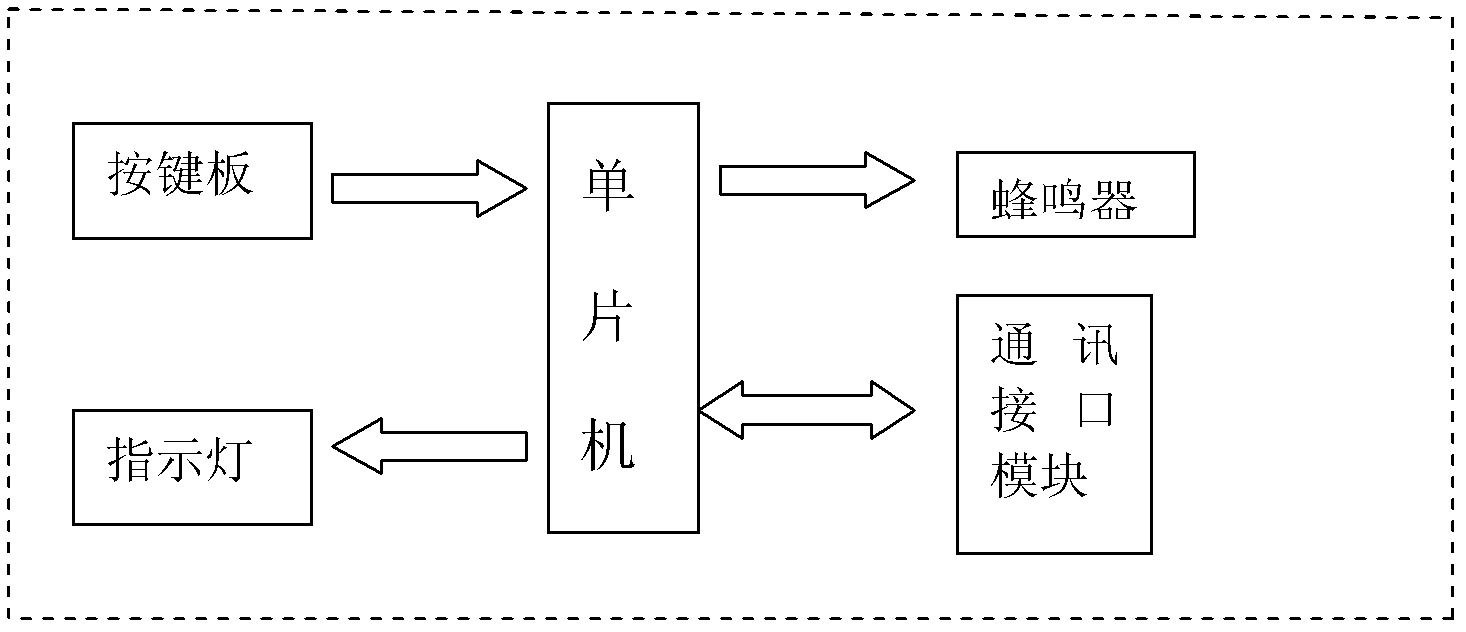

[0034] Multiple production line information collection terminals are used to collect the product type, production quantity, defective product type and defective quantity of the production line in real time, receive instructions from the control center management system and upload the collected data to the control center management system;

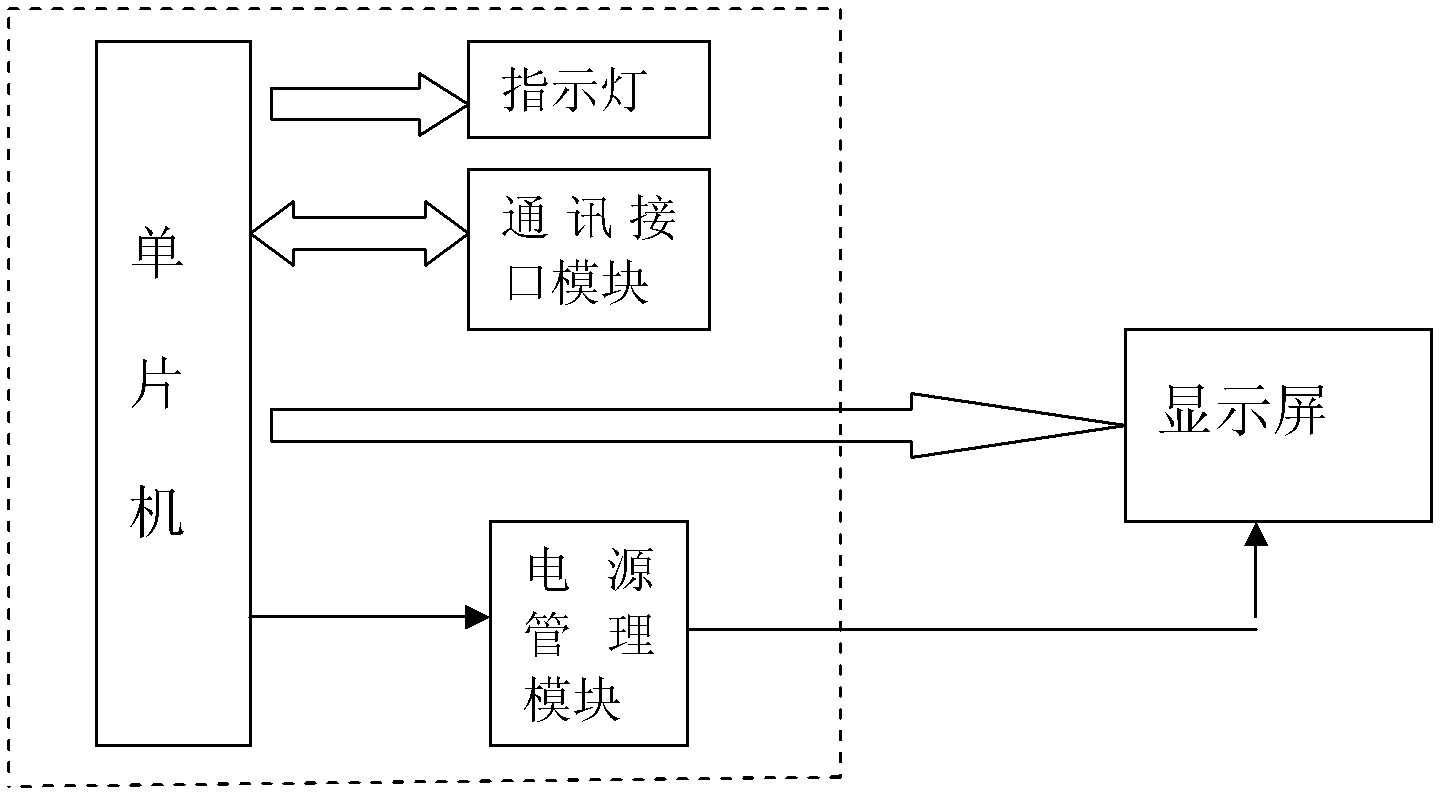

[0035] Multiple production line information display terminals are used to receive instructions issued by the control center management system and control the displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com