Spheroidized annealing technology for GCr15 bearing steel

An annealing process and bearing steel technology, applied in the field of spheroidizing annealing process, can solve the problems of long annealing time and unstable spheroidization quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

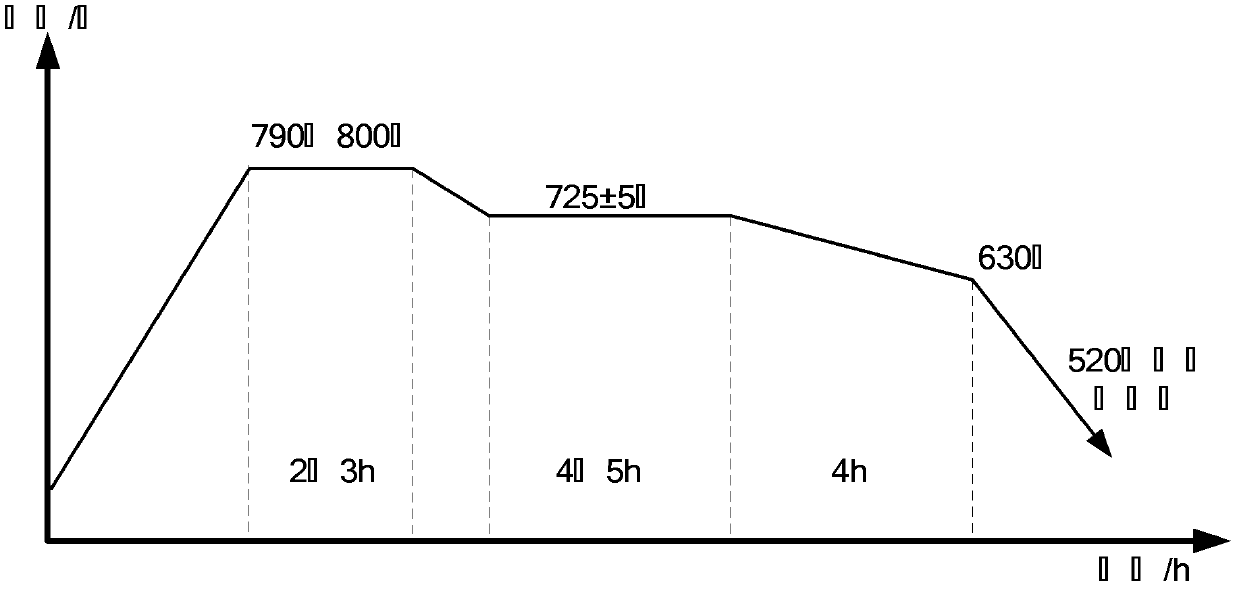

[0018] Such as figure 1 As shown, according to a GCr15 bearing steel spheroidizing annealing process implemented in the present invention, the temperature is raised to 790°C with the furnace, kept for 3 hours, then cooled to 720°C, and then slowly cooled to 630°C after kept for 4 hours, and then cooled to below 520°C and released from the furnace air cooled. After heat treatment with the spheroidizing annealing process provided by the present invention, the GCr15 bearing steel can obtain a fine and uniform spheroidized structure, the spheroidized structure is level 2, and the microstructure of the GCr15 bearing steel is fine tempered martensite + dispersed granular carbonization The hardness of the GCr15 bearing steel hot-rolled bar is 183HB, and the hardness dispersion of the same batch of steel is 12HB.

Embodiment 2

[0020] Such as figure 1 As shown, according to another GCr15 bearing steel spheroidizing annealing process implemented in the present invention, the temperature is raised to 800°C with the furnace, kept for 2 hours, then lowered to 720°C, and then slowly cooled to 630°C after held for 5 hours, and then cooled to below 520°C Remove from the oven and air cool. After heat treatment with the spheroidizing annealing process provided by the present invention, the GCr15 bearing steel can obtain a fine and uniform spheroidized structure, the spheroidized structure is grade 3, and the microstructure of the GCr15 bearing steel is fine tempered martensite + dispersed granular carbonization The hardness of the GCr15 bearing steel hot-rolled bar is 197HB, and the hardness dispersion of the same batch of steel is 14HB.

Embodiment 3

[0022] Such as figure 1 As shown, according to another GCr15 bearing steel spheroidizing annealing process implemented in the present invention, the temperature is raised to 790°C with the furnace, kept for 3 hours, then lowered to 730°C, and then cooled slowly to 630°C after holding for 4 hours, and then cooled to below 520°C Remove from the oven and air cool. After heat treatment with the spheroidizing annealing process provided by the present invention, the GCr15 bearing steel can obtain a fine and uniform spheroidized structure, the spheroidized structure is grade 3, and the microstructure of the GCr15 bearing steel is fine tempered martensite + dispersed granular carbonization The hardness of the GCr15 bearing steel hot-rolled bar is 199HB, and the hardness dispersion of the same batch of steel is 14HB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com