Method for designing mounted muffle for vertical bright annealing furnace

A design method and annealing furnace technology, applied in vertical furnaces, muffle furnaces, furnaces, etc., can solve problems such as section deformation, unreasonable length and thickness design, and reduced service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with implementation examples and accompanying drawings, but the present invention is not limited.

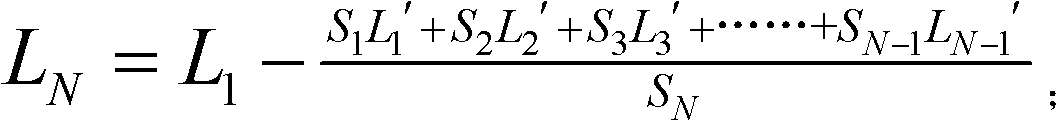

[0024] as attached figure 1 As shown, the thickness T of the single-section muffle material required for ten single sections 1 ,T 2 ,T 3 ,T 4 ,T 5 ,T 6 ,T 7 ,T 8 ,T 9 ,T 10 The order from thin to thick is 5mm, 6mm, 7mm, 8mm, 10mm, 12mm, 14mm, 17mm, 20mm, 22mm. The material specification of each single section muffle is that the maximum outer diameter after being curled into a full circle is 1710mm, and the maximum inner diameter is 1690mm. .

[0025] In this embodiment, the allowable stress σ=0.9N / mm is taken for each single-section muffle material 2 , preferably σ=0.8~1.2N / mm 2 .

[0026] Thickness is T 1 The single section formed by welding of the single section muffle material is at the bottom of the suspended whole section muffle; the theoretical length of the single section is L 1 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com