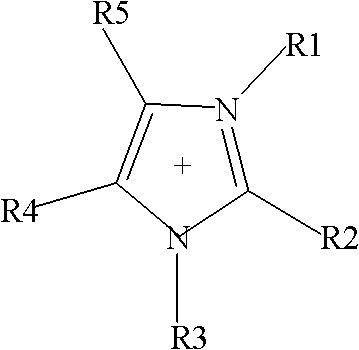

Method for preparing PIR (polyisocyanurate) material with ionic liquid catalyst

A technology of ionic liquid and catalytic preparation, applied in the field of PIR material preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

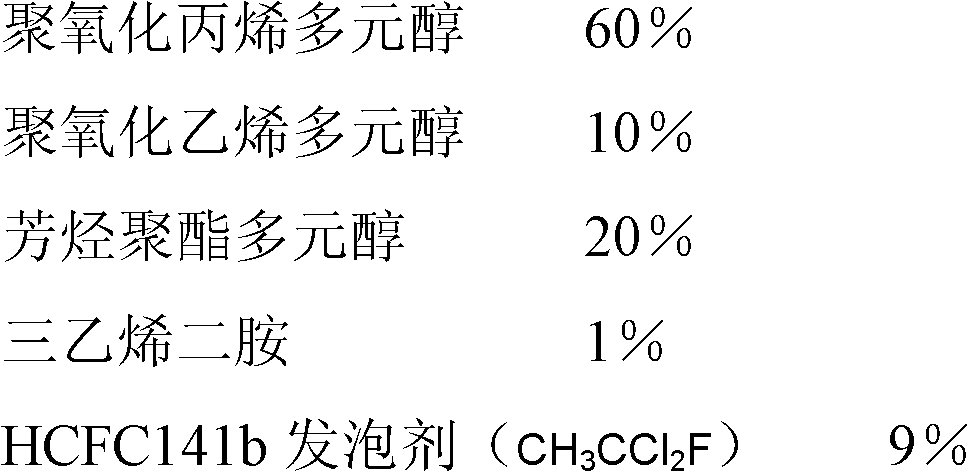

[0029] 3920g combined polyether, the hydroxyl value is about 200mgKOH / g, of which:

[0030]

[0031] Fully mix with 80g of ionic liquid AMIMCl at 40°C, and react with 6000g pMDI through a high-pressure machine into a mold, the material temperature is 25°C, the high-pressure machine pressure is 15MPa, and the mold temperature is 40°C. After 30 minutes demoulding, the obtained density is 70kg / m 3 of PIR material.

Embodiment 2

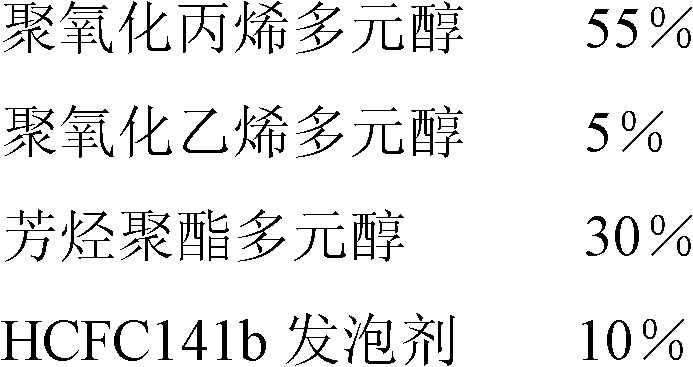

[0033] 7870g combined polyether, the hydroxyl value is about 180mgKOH / g, of which:

[0034]

[0035] Fully mixed with 130g ionic liquid BMIMBF4 at 20°C, and reacted with 16000g pMDI through a high-pressure machine and injected into a mold. The material temperature was 25°C, the high-pressure machine pressure was 35MPa, and the mold temperature was 50°C. After 60 minutes demoulding, the obtained density is 50kg / m 3 of PIR material.

Embodiment 3

[0037] 39200g combined polyether, the hydroxyl value is about 300mgKOH / g, of which:

[0038] Polyoxypropylene polyol 85%

[0039] Polyoxyethylene polyol 2%

[0041] (hydroxyl value is about 240mgKOH / g) and 800g ionic liquid BMIMCH 3 COOH was fully mixed at 20°C, and reacted with 80,000g pMDI through a high-pressure machine and injected into the mold. The material temperature was 25°C, the pressure of the high-pressure machine was 45MPa, and the mold temperature was 60°C. After 600 minutes demoulding, the obtained density is 500kg / m 3 of PIR material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com