Telescopic compound fertilizer rotary drum granulator

A technology of rotary drum granulator and compound fertilizer, which is applied in fertilizer form, fertilization device, fertilizer mixture, etc., can solve the problems of low product yield, easy agglomeration, low output, etc. The effect of small land area and high granulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

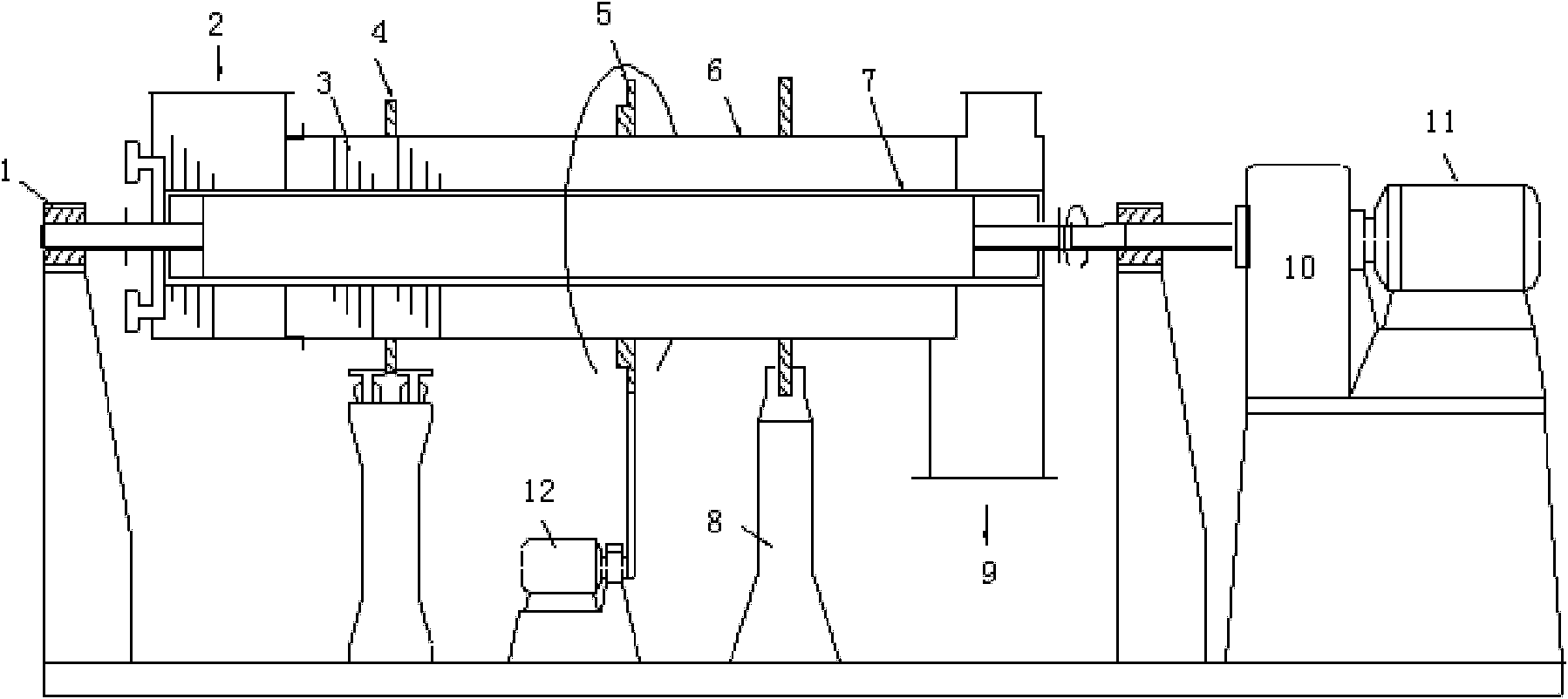

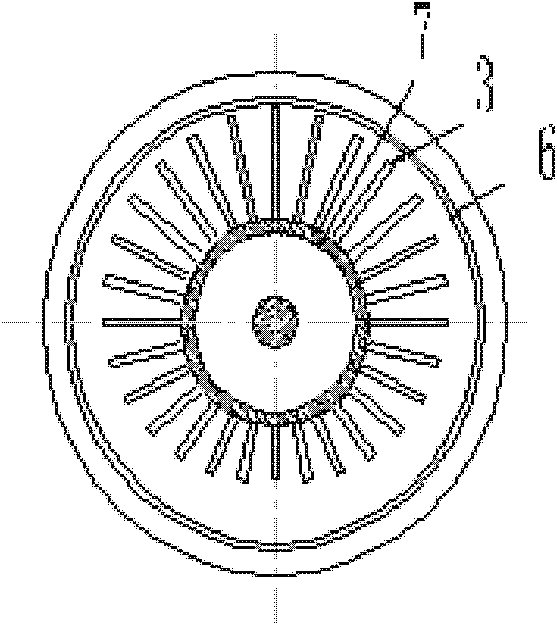

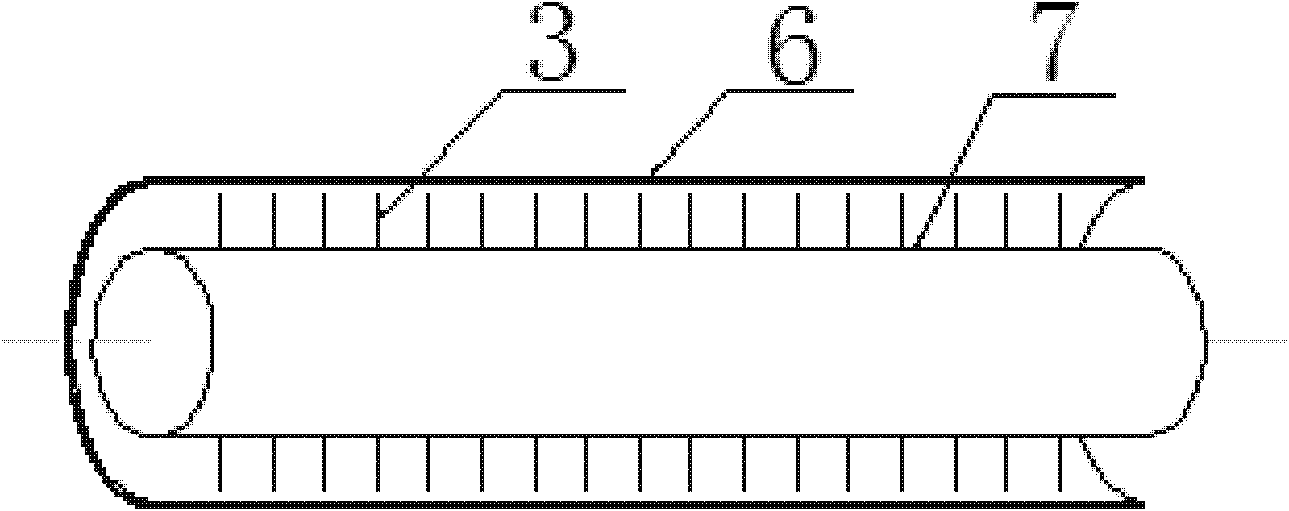

[0023] like Figures 1 to 4 As shown, a sleeve-type compound fertilizer rotary drum granulator includes a bracket 1, a feeding port 2, a granulating rod 3, a supporting wheel 4, a gear 5, an outer cylinder 6, an inner cylinder 7, a frame 8, The discharge port 9, the deceleration mechanism 10, the first motor 11, the second motor 12, the bracket 1 is provided with two, respectively located at both ends of the inner cylinder 7, and the inner cylinder 7 is rotatably arranged on the bracket through the rotating shaft 1, and connect the deceleration motor 10 and the first motor 11 through the rotating shaft, the inner cylinder 7 is provided with an outer cylinder 6 with the same rotation speed and different rotation speed, and the outer cylinder 6 is arranged on the frame 8 through the outer wall supporting wheel 4 The outer wall of the outer cylinder 6 is also provided with a gear 5, and the outer cylinder 6 is connected to the motor through the gear 5. One end of the outer cylind...

Embodiment 2

[0028] The rotating speed of the inner cylinder is 50 rpm, and the rotating speed of the outer cylinder is 5 rpm. The rest are the same as in Example 1.

Embodiment 3

[0030] The rotational speed of the inner cylinder is 100 rpm, and the rotational speed of the outer cylinder is 10 rpm. The rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com