100W aluminum nitride ceramic substrate loading chip with wide solder pad and 50 Ohms impedance

A technology of aluminum nitride ceramics and aluminum nitride substrates, applied in electrical components, circuits, waveguide-type devices, etc., can solve the problems affecting product return loss, convenience of welding, unfavorable welding firmness, burnout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

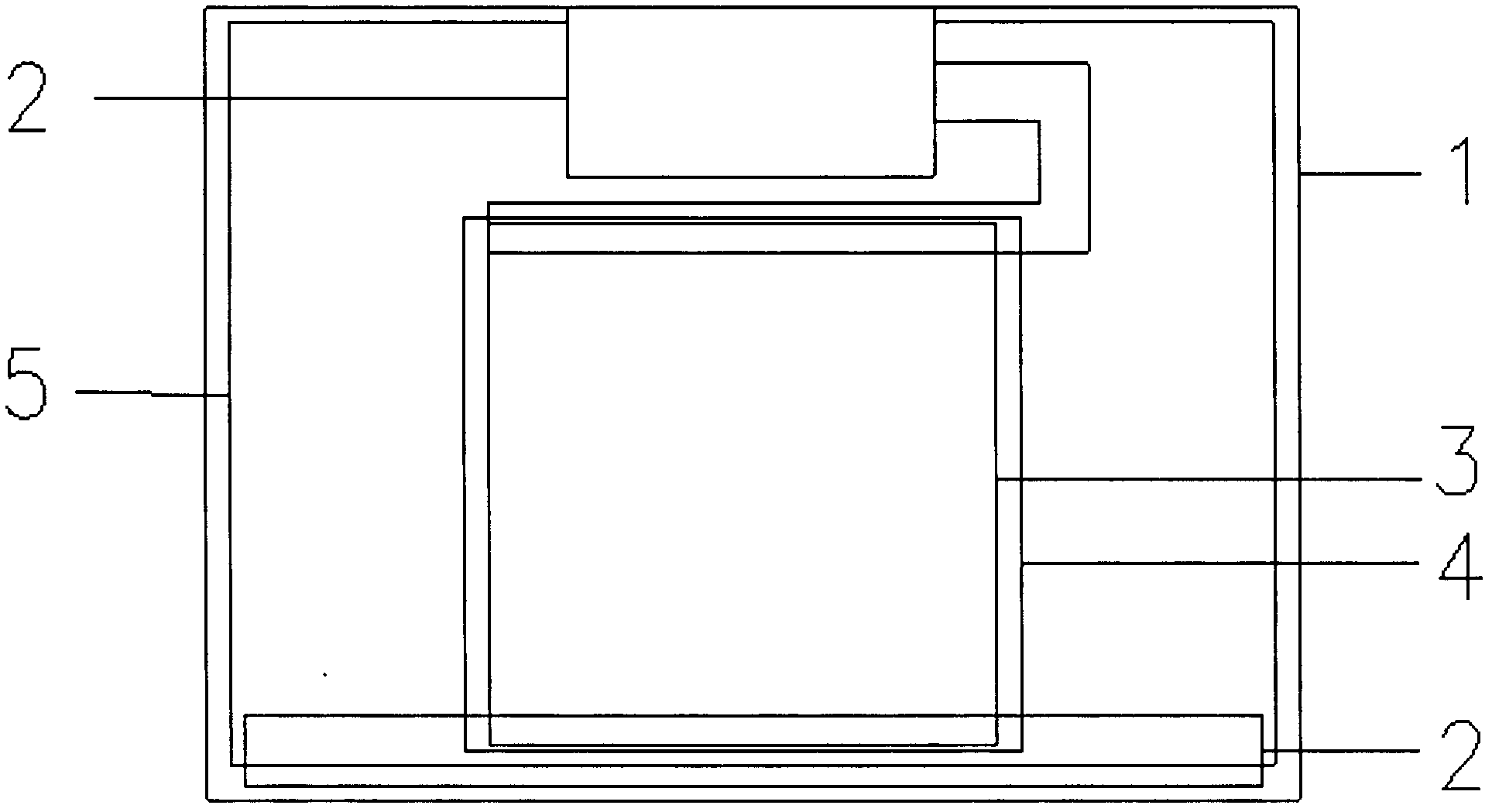

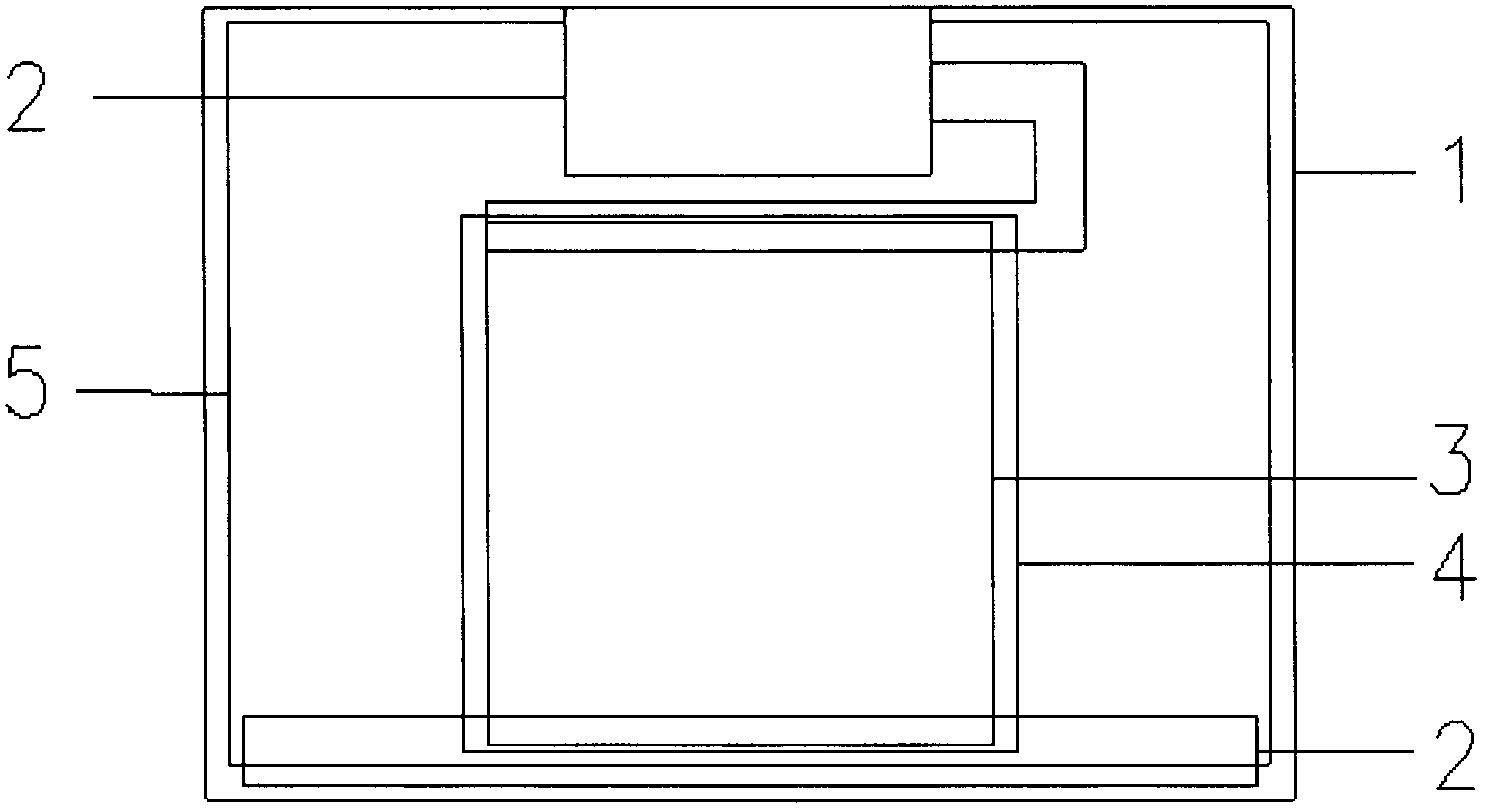

[0012] Such as figure 1 As shown, the wide pad impedance is 50Ω aluminum nitride ceramic substrate 100 watts load chip includes a 5.7*8.9*1.0mm aluminum nitride substrate 1, the back of the aluminum nitride substrate 1 is printed with a back conductive layer, aluminum nitride The front side of the substrate 1 is printed with a resistor 3 and a wire 2. The wire 2 is connected to the resistor 3 to form a load circuit. The ground terminal of the load circuit is electrically connected to the back conductive layer through silver paste, so that the load circuit is grounded and conducted. The back conducting layer and wire 2 are printed with conductive silver paste, and the resistor 3 is printed with resistive paste. A glass protective film 4 is printed on the resistor 3 . A layer of blue protective film 5 is also printed on the upper surfaces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com