Device and process for manufacturing positive/negative electrode material of lithium battery

A technology of negative electrode material and production equipment, which is applied in the field of solid-phase synthesis method to produce lithium battery positive electrode or negative electrode material, can solve the problems of inability to realize continuous production, low degree of automation, etc. The effect of stop feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

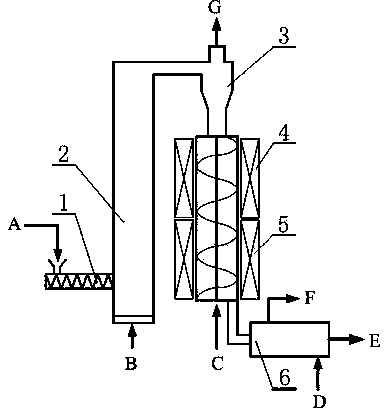

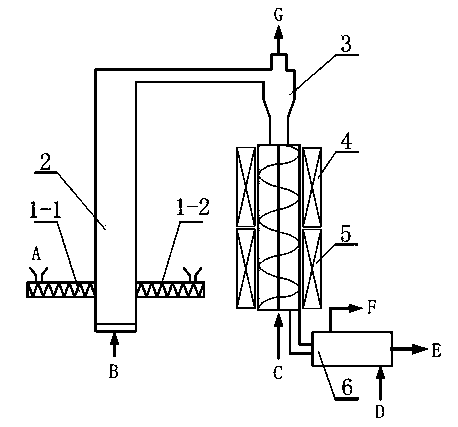

[0026] A kind of production technology of lithium manganate battery cathode material is as attached figure 2 As shown, lithium carbonate LiCO3 and manganese oxygen-containing compounds (such as Mn3O4, Mn2O3, MnO2, etc.) particles with a particle size of 0.1-100 μm are respectively fed into the first feeding device 1-1 and the second feeding device 1-2 Fluidized bed mixing device 2, in the fluidized bed mixing device 2, particles of lithium carbonate LiCO3 and manganese oxygen-containing compounds (such as Mn3O4, Mn2O3, MnO2, etc.) Flue gas) is fluidized and fully mixed, and after being separated by the gas-solid separator 3, it enters the preheating section 4 of the spiral continuous feeding reaction device. The mixture of lithium carbonate LiCO3 and manganese oxygen-containing compounds (such as Mn3O4, Mn2O3, MnO2, etc.) is preheated for several hours and then directly enters the reaction section 5 of the spiral continuous feeding reaction device. In the reaction section 5 o...

specific example 2

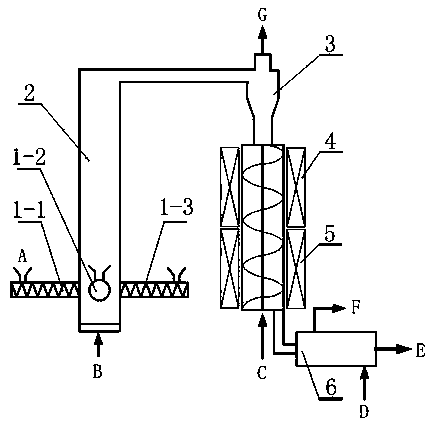

[0028] A kind of production technology of lithium iron phosphate battery cathode material such as image 3 As shown, lithium carbonate, ferric phosphate (or ferrous phosphate), and reducing agent particles with a particle size of 0.1-100 μm are respectively fed by the first feeding device 1-1, the second feeding device 1-2 and the third feeding device 1-3 enter the fluidized bed mixing device 2, in the fluidized bed mixing device 2, lithium carbonate, iron phosphate (or ferrous phosphate), and reducing agent particles are fed into the fluidized bed mixing device 2 by nitrogen (or air or heat) Flue gas) is fluidized and fully mixed, and after being separated by the gas-solid separator 3, it enters the preheating section 4 of the spiral continuous feeding reaction device. Preheat the mixture of lithium carbonate, ferric phosphate (or ferrous phosphate) and reducing agent particles for 5 hours and then directly enter the reaction section 5 of the spiral continuous feeding reactio...

specific example 3

[0030] A kind of production technology of ternary type lithium battery cathode material is as follows figure 2 As shown, particles such as lithium carbonate, Ni-oxygen compound, Co-oxygen compound, Mn-oxygen compound with a particle size of 0.1-100 μm are respectively fed by the first feeding device 1-1 and the second feeding device 1- 2 Add the fluidized bed mixing device 2, in the fluidized bed mixing device 2, particles such as lithium carbonate, Ni-oxygenate, Co-oxygenate, Mn-oxygenate are fed into the fluidized bed mixing device 2 by nitrogen gas Realize fluidization and fully mix, and enter the preheating section 4 of the spiral continuous feeding reaction device after being separated by the gas-solid separator 3. In the preheating section 4 of the spiral continuous feeding reaction device at a temperature of 200-600 ° C, lithium carbonate , Ni-oxygenate, Co-oxygenate, and Mn-oxygenate particles are preheated for 2 to 15 hours and then directly enter the reaction sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com