Automatic exhausting machine of electrodeless lamp

A technology of circular exhaust machine and electrodeless lamp, which is applied in the direction of electric tube/lamp exhaust, etc., which can solve the problems of inability to discharge miscellaneous gas, prolonged pumping time, and long heating time, so as to reduce internal pressure, increase gas purity, prevent The effect of a sudden increase in temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

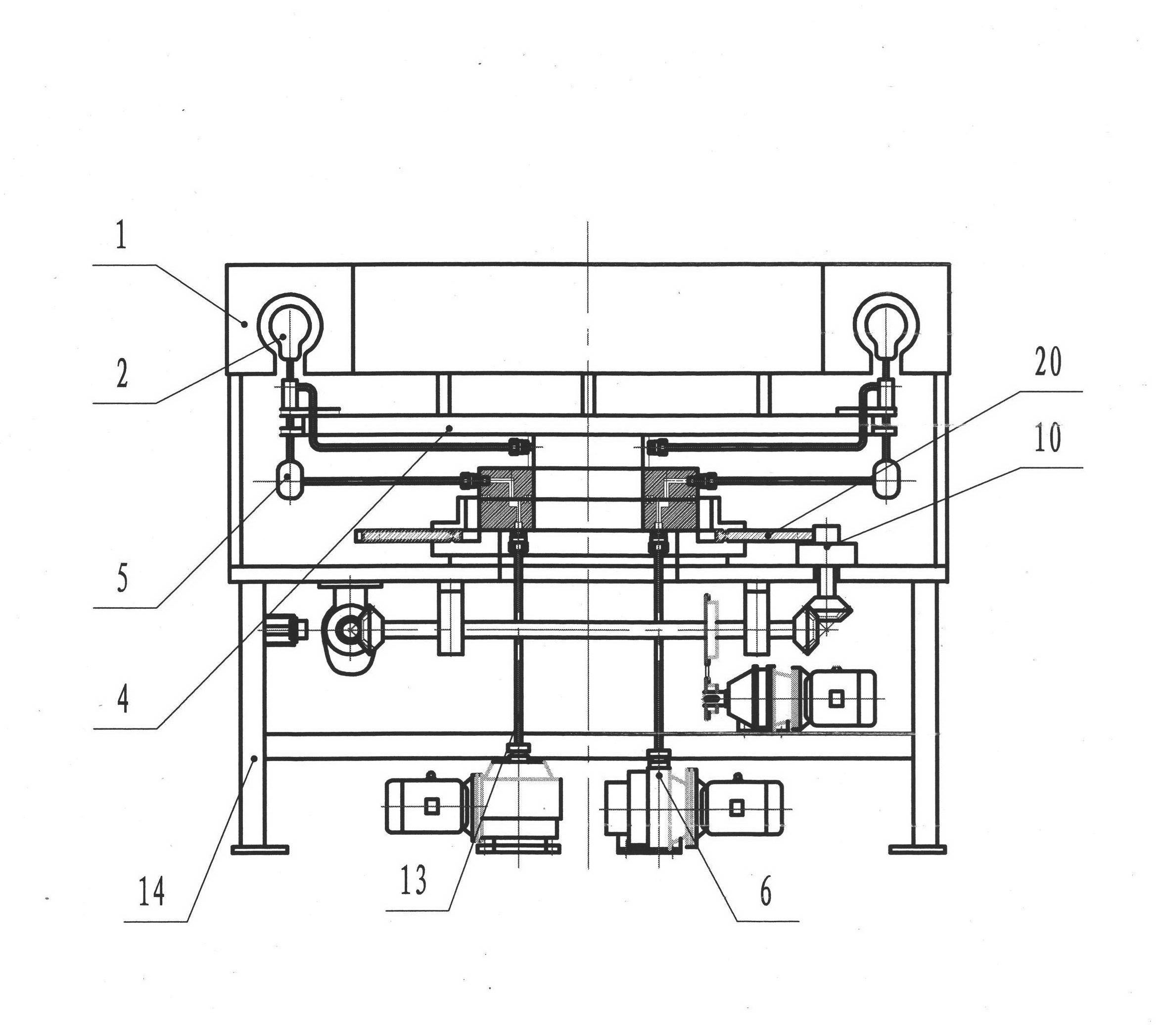

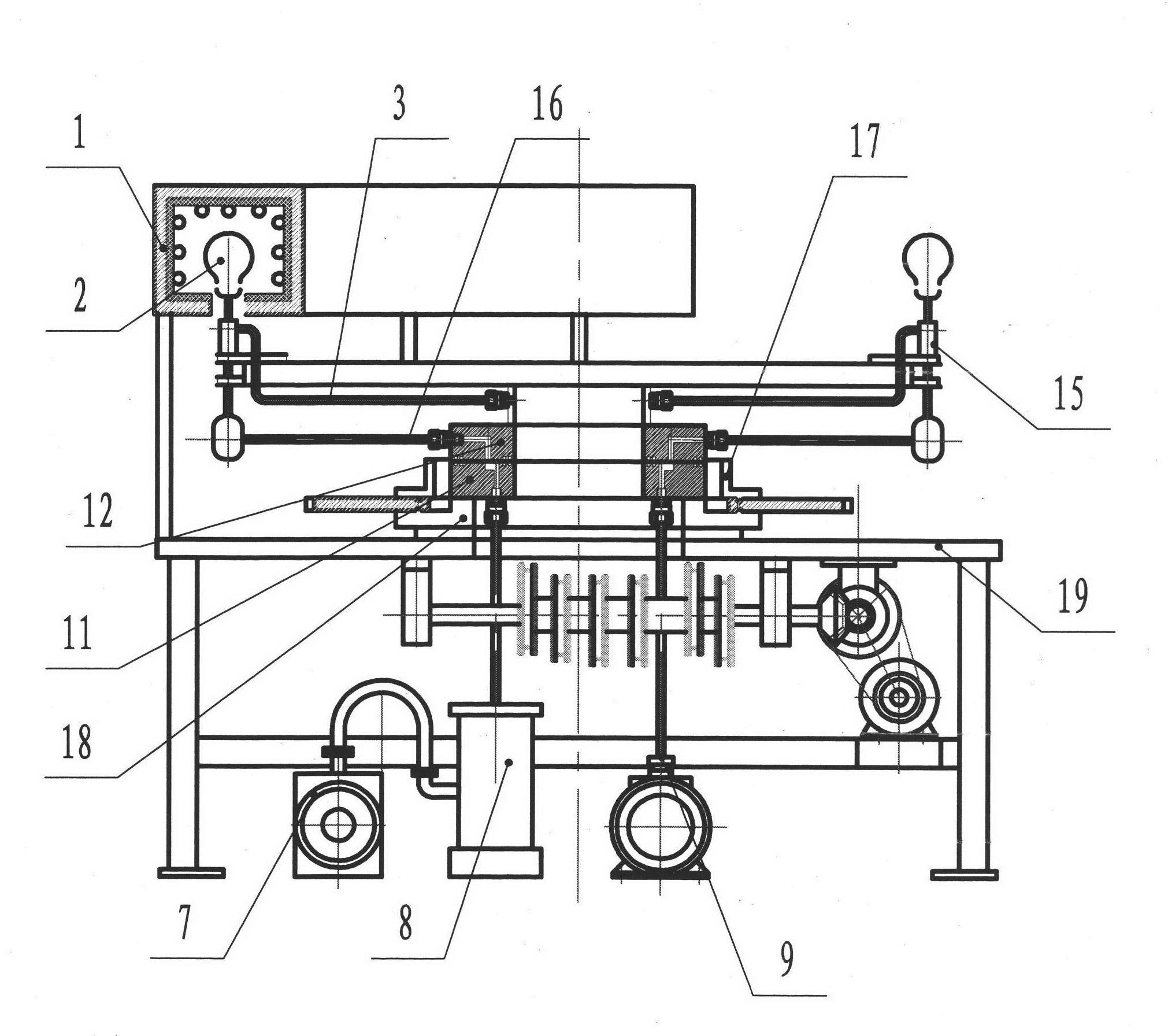

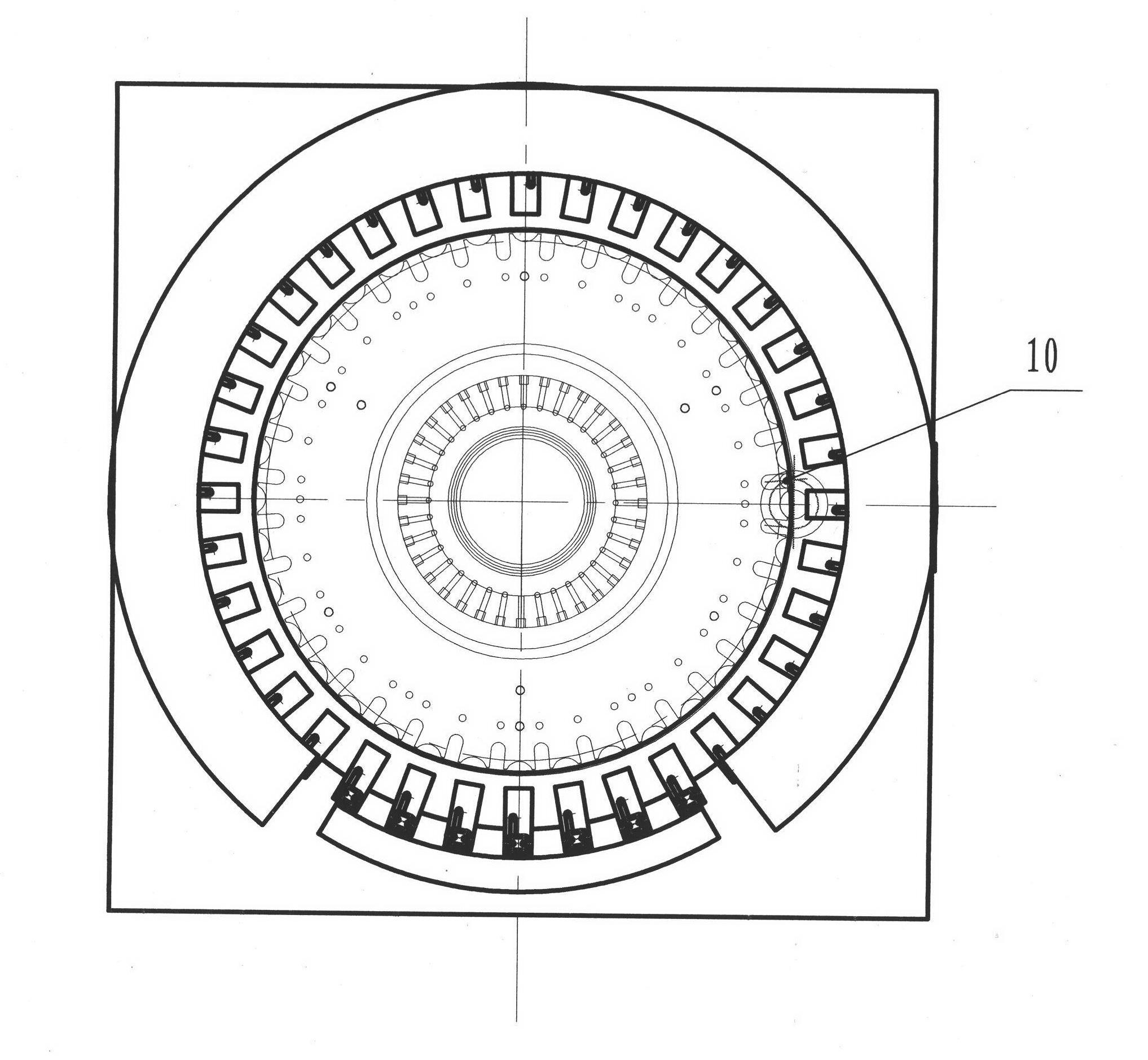

[0022] Embodiment one: see Figure 1-Figure 3 , an automatic round row machine for electrodeless lamps in the figure, including a frame, a center plate installed on the frame, an oven, and an air pump. Several automatic sealing devices are evenly distributed on the circumference of the center plate. The upper side of the separation device is connected with a trachea A, and the lower end is connected with a collector, and the lower part of the collector communicates with the air hole on the upper sealing disc through the trachea B; the lower part of the periphery of the upper sealing disc is connected with a bracket, and the lower part of the bracket is connected There is a shift plate, and a shift fork is distributed around the dial; the rack platform is provided with a shift pin to match the above shift fork; the lower part of the upper sealing disc body is provided with a lower sealing disc body, the upper, The contact surface between the lower sealing discs is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com