Rotary current stabilizer

A current stabilizer and rotary technology, which is applied in the direction of instruments, fluid velocity measurement, and measurement flow/mass flow, etc., can solve the problems of decreased measurement accuracy, increased probability of turbulent vortex flow, unstable fluid, etc., to achieve the goal of containing The effect of reducing the diffusion rate of substances, reducing the probability of eddy flow, and reducing the pulsation amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

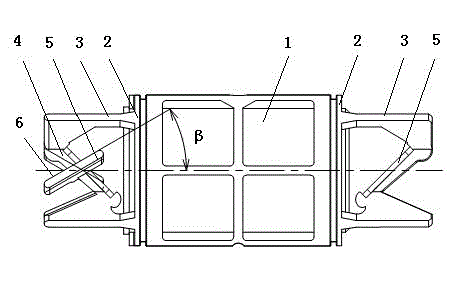

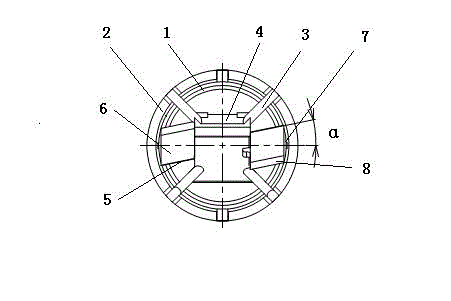

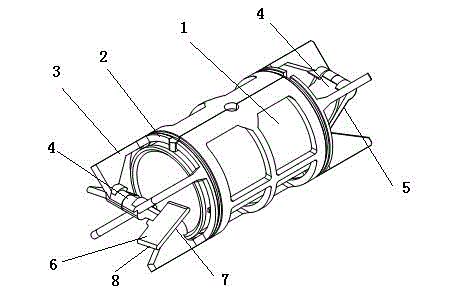

[0022] Embodiment 1: the present invention can have 2 rotating vanes 5 in the side circumferential array of mirror frame 4, and rotating vane 5 is square plate shape, and the angle between the upper surface 6 of rotating vane 5 and its outer side 7 is 80 °, so that The radial deflection angle of the rotating blade 5 relative to the steady flow pipe body 1 α is 10°, the upper end surface 8 is a transitional arc surface, in order to reduce the resistance of the fluid and avoid the pulsation amplitude, the rotating blade 5 is axially inclined, and the angle between the inclined surface 6 and the axis of the steady flow pipe body 1 β Between 20° and 45°, it is beneficial to guide the unstable fluid through the rotating blade 5 to form a stable swirling fluid, so that the flow velocity of the fluid passing through the ultrasonic region reaches a stable state, which has the effect of accurate measurement.

Embodiment 2

[0023] Embodiment 2: The present invention can have 4 rotating blades 5 in the circumferential array between mirror bracket 2, and rotating blade 5 is fixedly connected with mirror bracket 2 through connecting block 9, and the upper end surface of rotating blade is from the inside to the outside and between the mirror bracket. The connecting surface between them is arc-shaped transition, and the angle between the upper surface of the rotating blade and the outer surface is 80°, so that the radial deflection angle of the rotating blade relative to the steady flow pipe body α 10°, in order to reduce fluid resistance and avoid pulsation amplitude, the rotating blade 5 is axially inclined, and the angle between the inclined surface 6 and the axis of the steady flow pipe body 1 β Between 20° and 45°, it is beneficial to guide the unstable fluid through the rotating blade 5 to form a stable swirling fluid, so that the flow velocity of the fluid passing through the ultrasonic region c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com