Quick pipeline heater

A pipeline heater, extremely fast technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of easy scaling, strong corrosion of scale, internal heat rise, etc., to reduce descaling pickling , not easy to scale, strong magnetizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

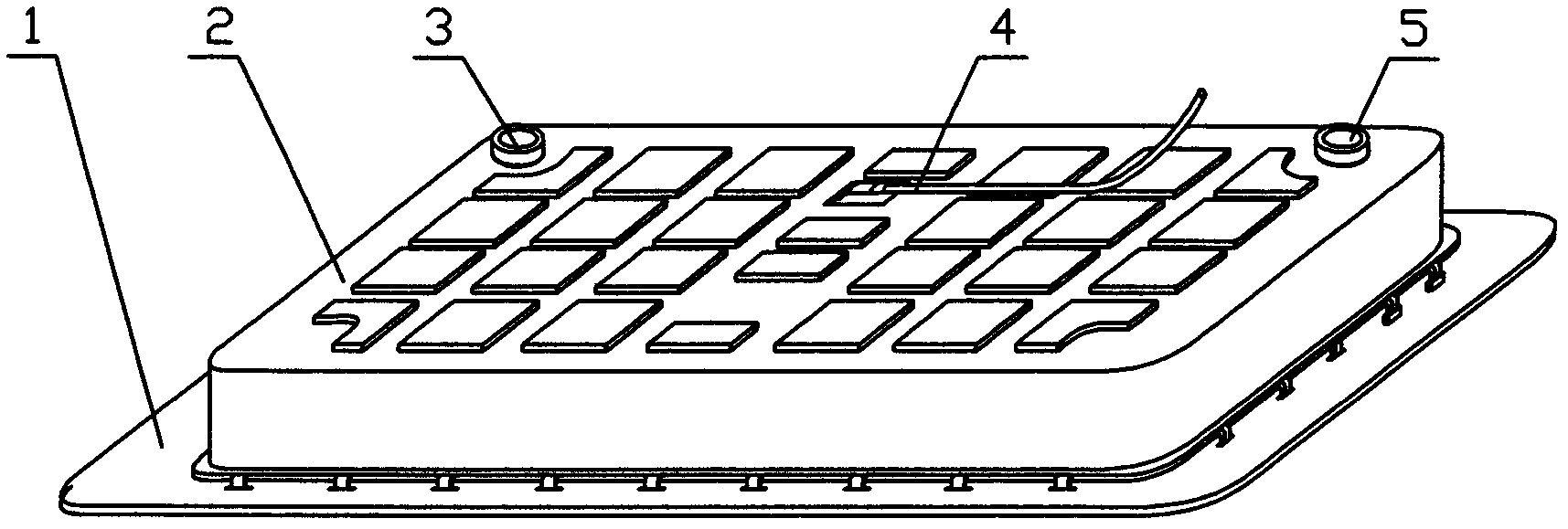

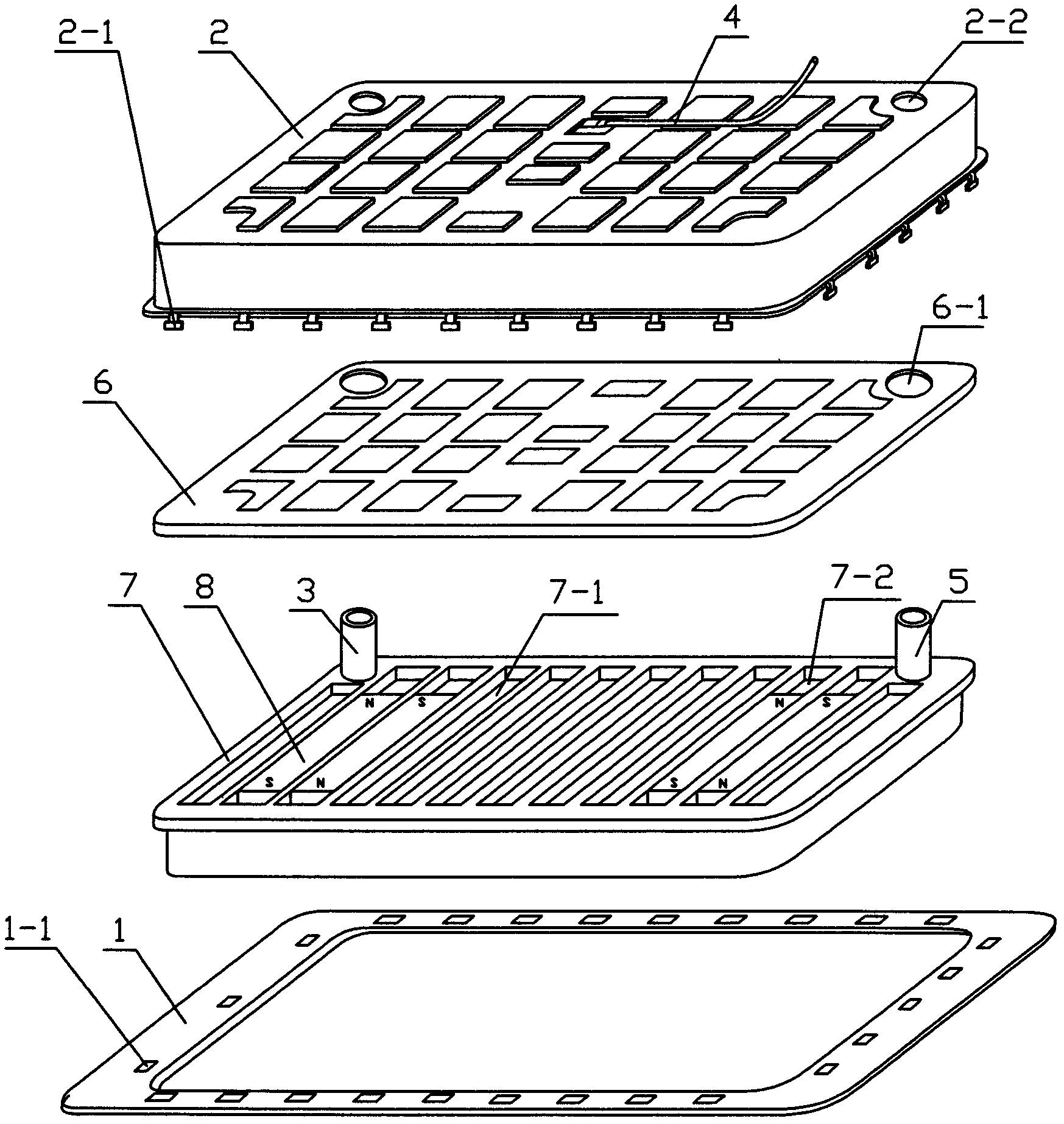

[0015] The embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0016] The heating plate 1 is made of alloy material in the shape of a basin, with a mounting hole 1-1 on the periphery, an electric heating film 1-2 and two terminals 1-3 on the outer surface, which are used to sense and adjust the temperature of the heating plate. Resistors 1-4, thermistor leads 1-5, such as figure 2 , Image 6 shown.

[0017] A ground wire 4 is welded and fixed on the casing 2, a connection buckle 2-1 is arranged on the lower periphery, and a mounting hole 2-2 is arranged at the edge of the upper surface.

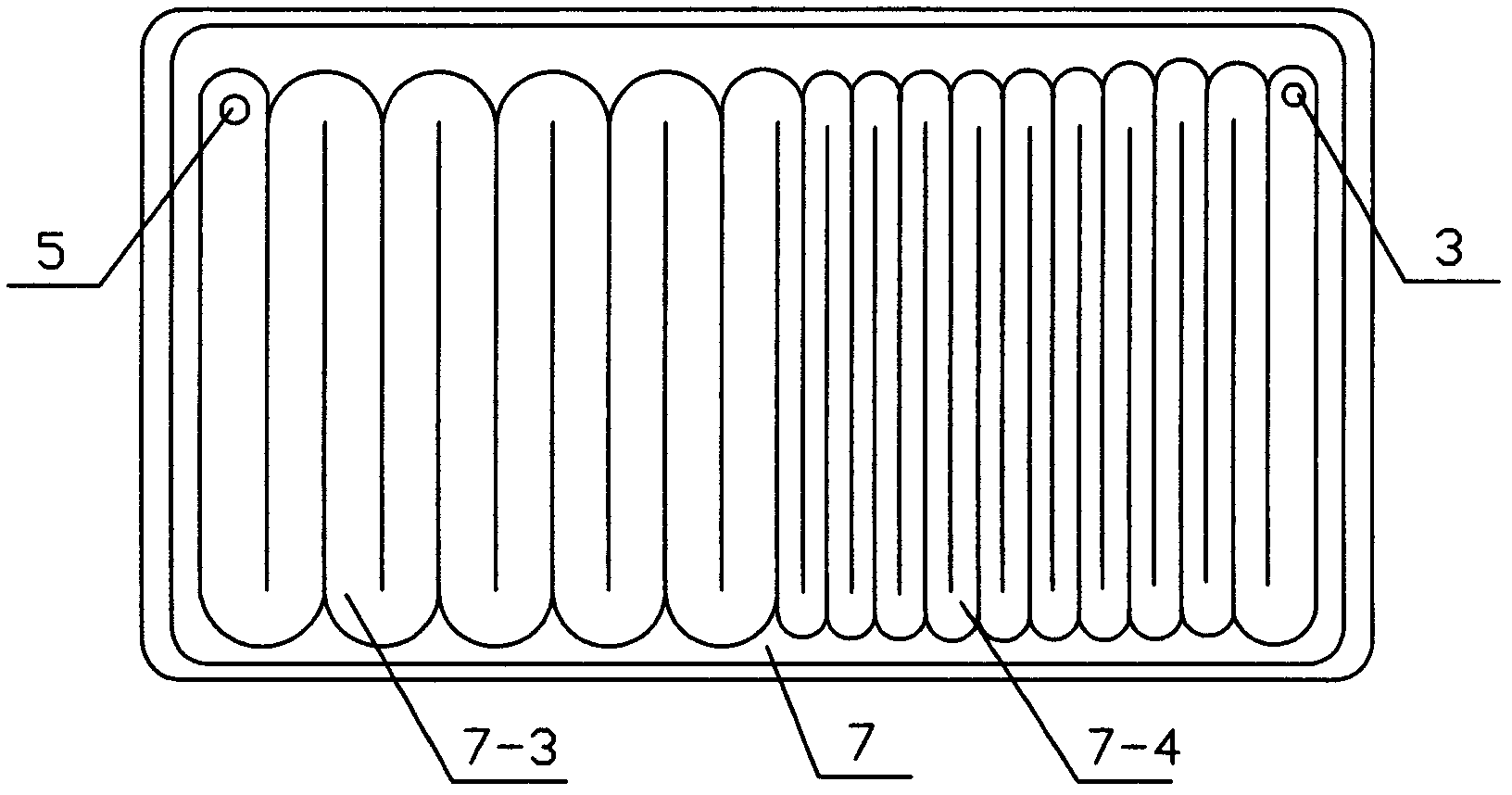

[0018] There are inlet and outlet pipes 3 and 5 on the two edges of the upper surface of the silica gel body 7. In order to increase the strength of the silica gel body and reduce weight and save materials, there are also incompatible and different sizes of grooves 7-1 composed of parallel reinforcing ribs. , Groove 7-2.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com