Novel heating system

A heating system, a new type of technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of not meeting the design requirements, the surface size cannot be arbitrarily large, slow heating, etc., to achieve short heat transfer path, easy assembly and maintenance , Good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

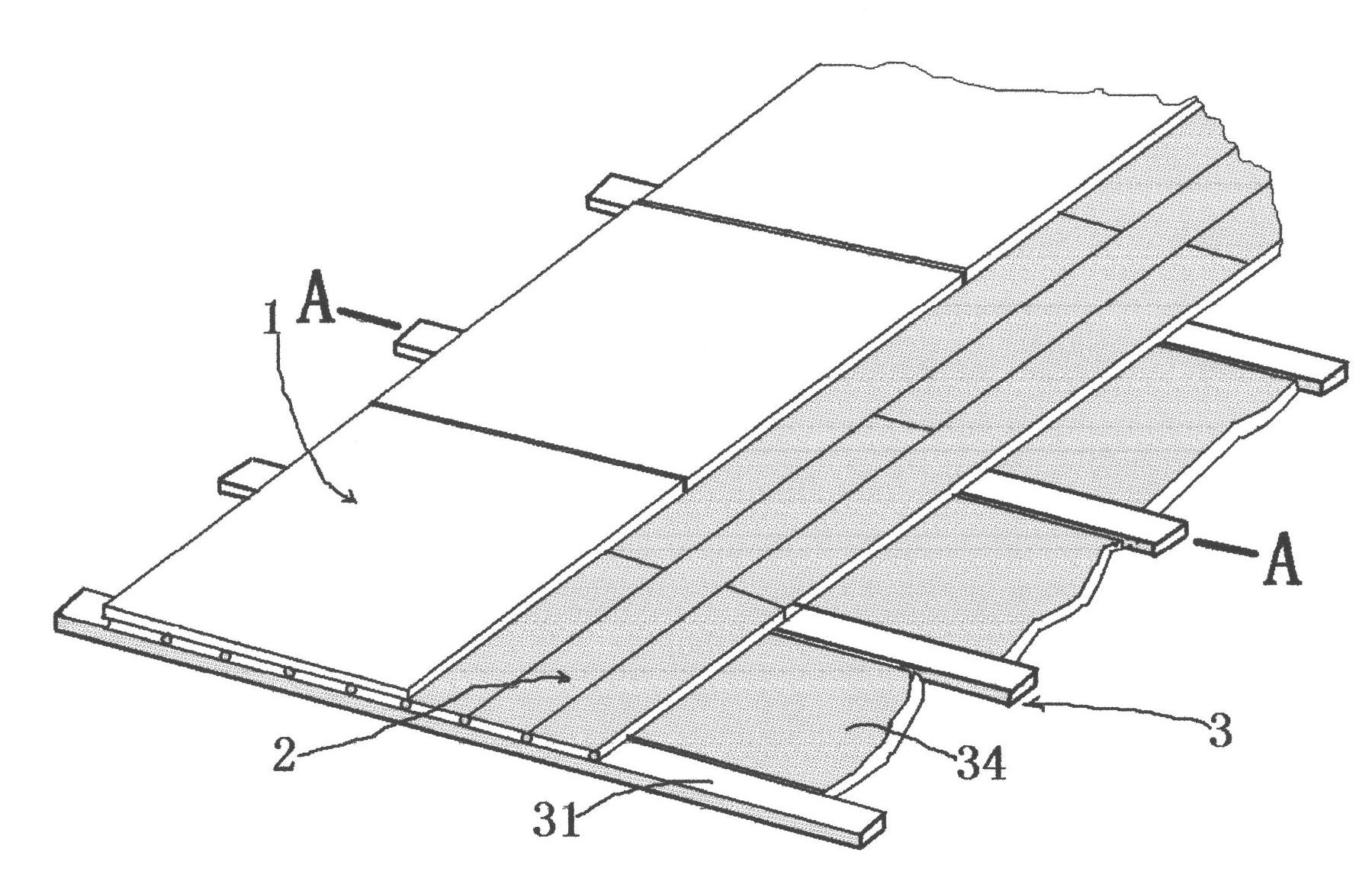

[0028] Such as figure 1 , 2, 3, 4, 5 and 6, the new heating system includes a decorative surface layer 1, a base plate 2, and a heat insulation layer 3. It is characterized in that the base plate 2 includes a base plate body 22 and a heat-conducting material. The thermally conductive medium layer 23 is provided with a first structure 221 on one side of the substrate body 22 and a second structure 222 on the other side. The first structure 221 on one substrate body 22 and the second structure on another substrate body 22 adjacent The two structures 222 can surround each other, and when the first structure 221 and the second structure 222 are surrounded, a longitudinally extending accommodation cavity 223 can be formed. The heat-conducting medium layer 23 is made of a heat-conducting material and is composited on the substrate body 22 On the front side, the heat conduction medium layer 23 includes a heat conduction portion 230 located on the front surface of the substrate body ...

Embodiment 2

[0032] Such as Figure 7 , 8 As shown in and 9, in this embodiment, the side of the heat conducting part 230 facing the substrate body 22 has a longitudinally extending concave convex body 234, and the substrate body 22 is provided with a longitudinally extending groove body for placing the above-mentioned concave convex body 234. 224. The concave convex body 234 is located on the center line of the heat conducting part 230 , and another heating body 4 is installed in the concave convex body 234 . The rest are similar to those in Example 1, and will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com