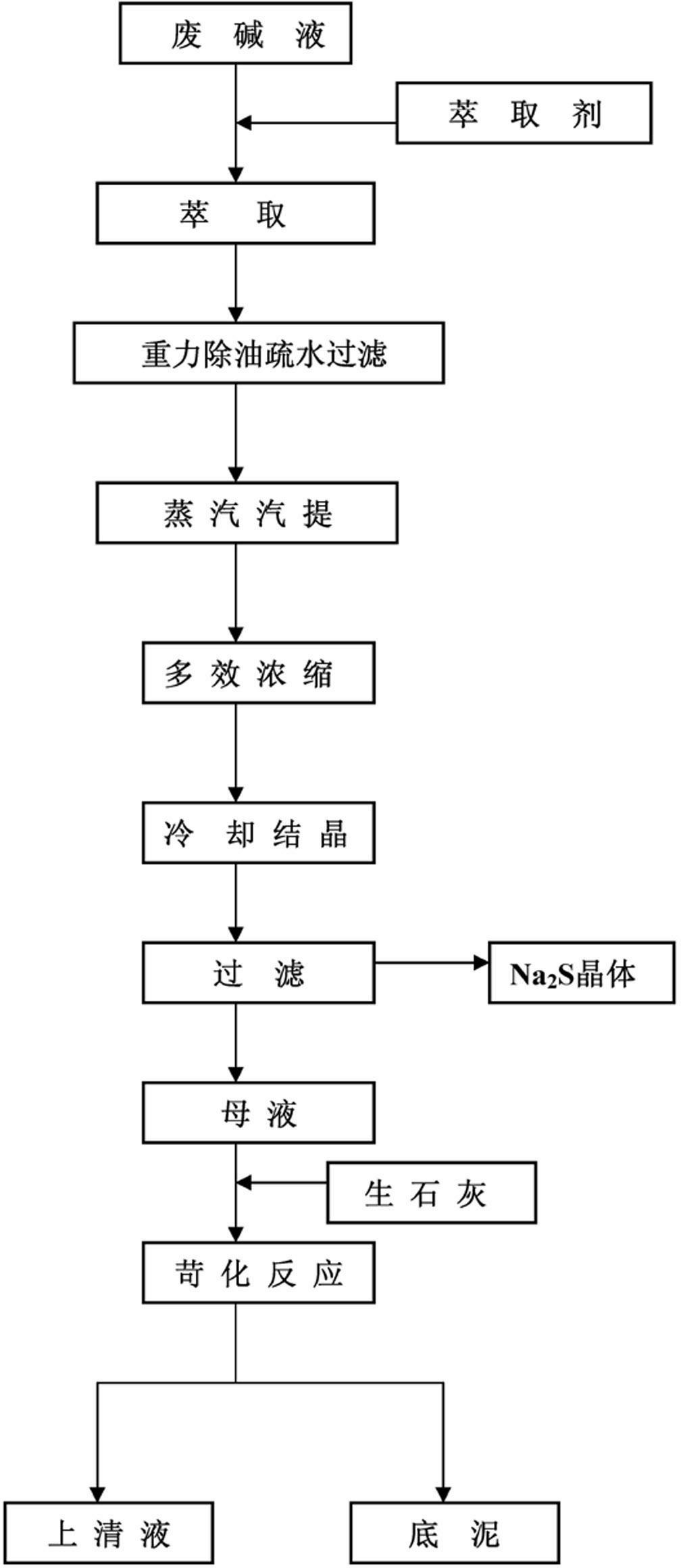

Circular and comprehensive utilization method for ethylene alkali waste liquid

A technology for ethylene waste lye and waste lye, which is applied in the fields of waste lye recycling and comprehensive utilization and ethylene waste lye recycling and comprehensive utilization. Poor quality and other problems, to achieve the effect of saving resources and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Taking an ethylene plant with an annual output of 1 million tons / a as an example, the waste lye produced by the 1 million tons / a production device is about 100,000 tons / a. Using the technology of the present invention, the investment of a complete set of equipment is about 20 million yuan, which can produce soda sulfide (with 40%Na 2 S) 10,000 tons / a, producing 24,000 tons / a sodium hydroxide solution (containing 18% NaOH), the output value is about 26 million yuan / a, and the profit is 200 / a;

[0045] At present, domestic ethylene mostly uses Siemens wet oxidation technology to pretreat ethylene waste lye, and then sends it to biochemical treatment, and discharges it after reaching the standard. Taking the ethylene plant with an annual output of 1 million tons / a as an example, the waste lye produced by the 1 million tons / a production plant is about 100,000 tons / a, the investment in wet oxidation technology equipment is about 50 million yuan, and the investment in biochem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com