Membrane separation system and purification method for purifying camphorsulfonic acid solution

A technology of membrane separation system and camphorsulfonic acid solution, which is applied in the membrane separation system and purification field of purifying camphorsulfonic acid solution, can solve the problems of high processing cost, easy deterioration and loss of materials, and achieve low energy consumption, simple maintenance, The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

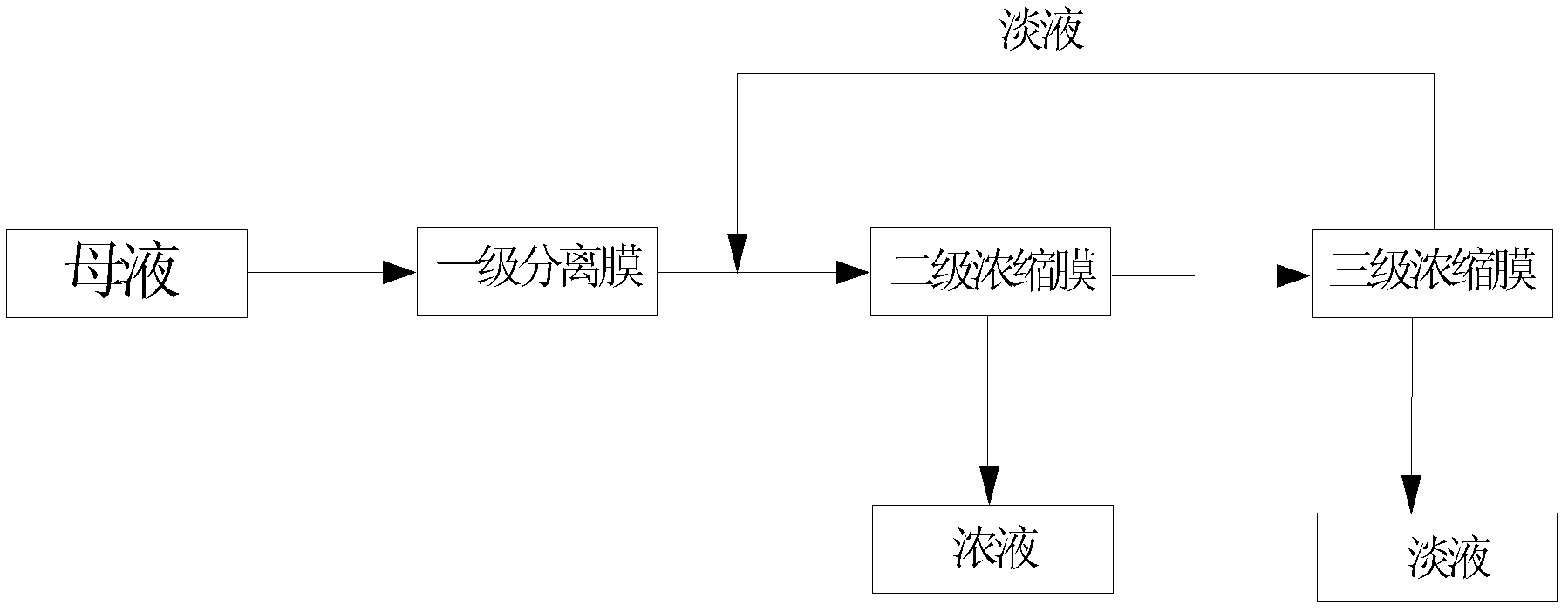

[0020] Take the first membrane separation system for purification, take 10000L of 7% camphorsulfonic acid solution and transport it to the first-stage 0.05um cellulose acetate roll-type ultrafiltration membrane module through a high-pressure pump, control the pump outlet pressure to 0.8Mpa, intercept and separate camphorsulfonic acid A small amount of polymer aggregates and solid suspended matter in the mother liquor, the pre-purified camphorsulfonic acid mother liquor enters the secondary 8nm cellulose acetate roll-type nanofiltration membrane module, separates the camphorsulfonic acid concentrated solution with a molecular weight of 232, and enters the mother liquor In the collection tank, the dilute liquid continues to be pumped into the third-stage 3nm cellulose acetate roll-type nanofiltration membrane module, the separated dilute liquid is discharged from the membrane separation system, and the concentrated liquid is returned to the secondary membrane to continue concentra...

Embodiment 2

[0022] Take the second membrane separation system for purification, take 10,000L of 6% camphorsulfonic acid solution and transport it to the first-stage 0.03um polyethersulfone tubular ultrafiltration membrane module through a high-pressure pump, control the pump outlet pressure to 0.9Mpa, and intercept and separate camphorsulfonic acid A small amount of polymer aggregates and solid suspended matter in the mother liquor, the pre-purified camphorsulfonic acid mother liquor enters the secondary 10nm polyethersulfone nanofiltration membrane module, separates the camphorsulfonic acid concentrated solution with a molecular weight of 232, and enters the mother liquor collection tank , the dilute liquid continues to be pumped into the third-stage 5nm polyethersulfone tubular nanofiltration membrane module, the separated dilute liquid is discharged from the membrane separation system, and the concentrated liquid is returned to the second-stage membrane to continue concentration and sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com