Multifunctional tail vapor surplus heat utilizing device

A multi-functional, steam technology, applied in the direction of heating devices, heat exchange equipment, heat exchanger types, etc., can solve problems such as energy waste, white clouds rolling, environmental pollution, etc., to reduce production costs, prevent noise pollution, and improve competitiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

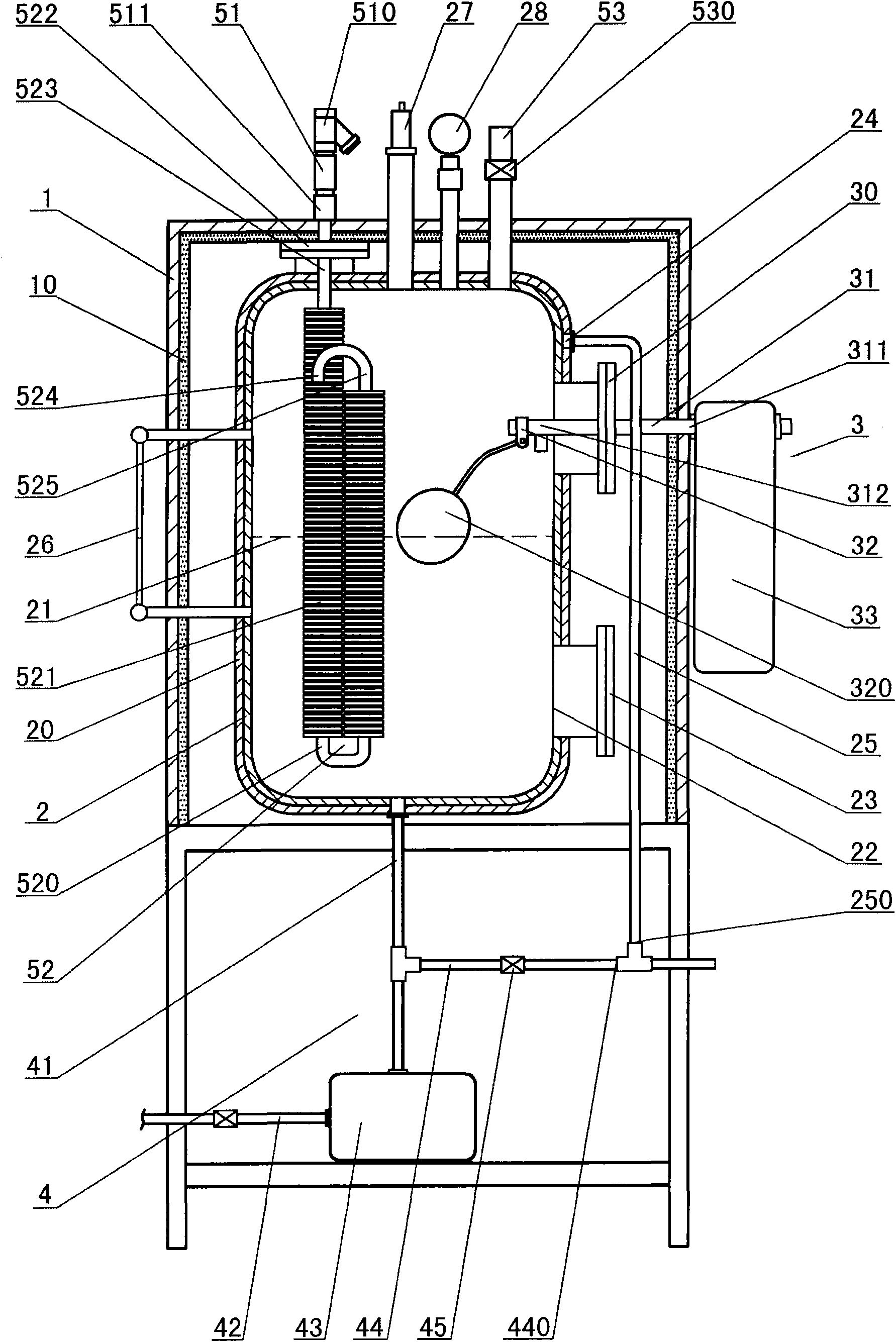

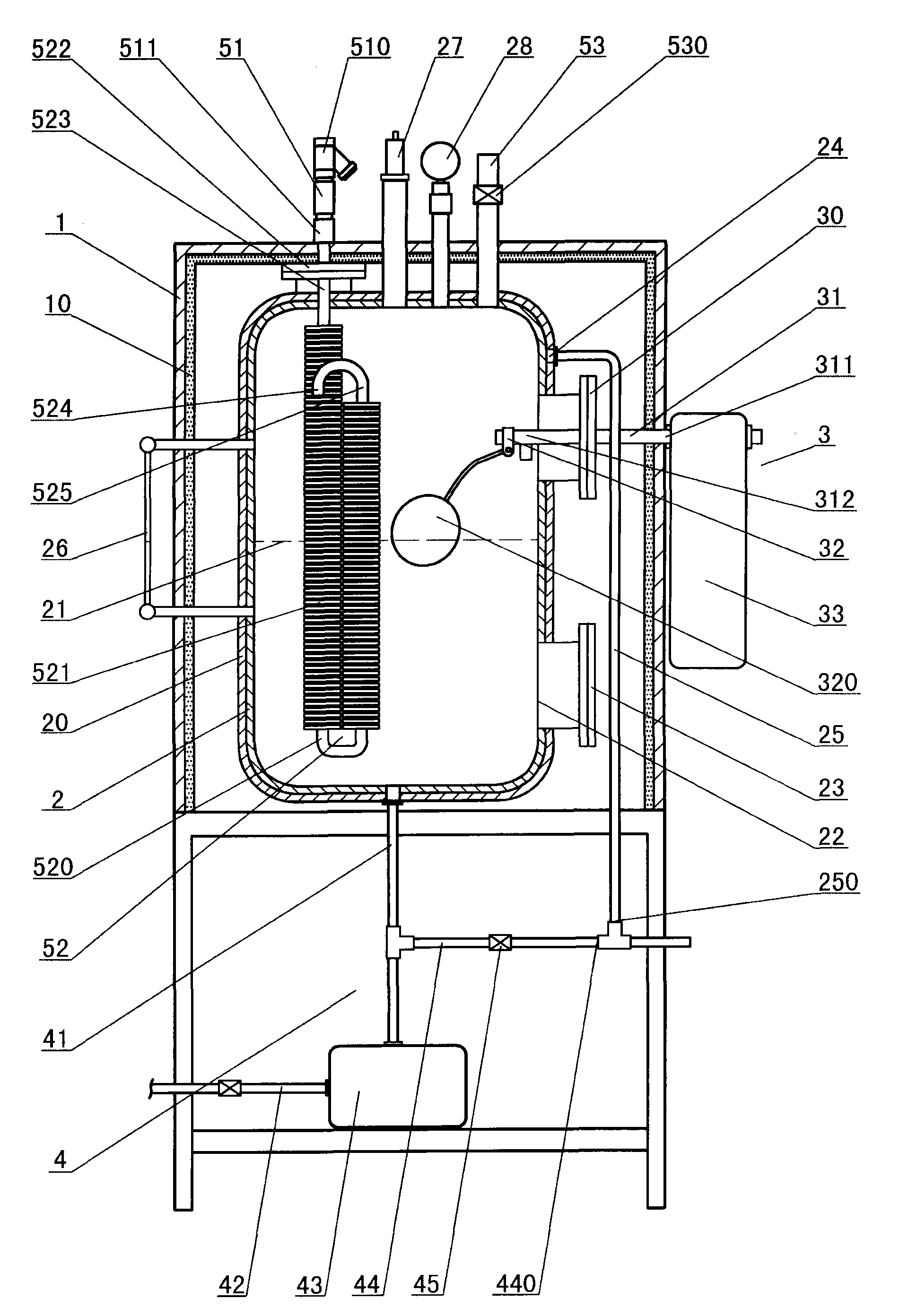

[0029] As shown in the accompanying drawings, the multifunctional steam exhaust heat utilization device in this preferred embodiment includes a housing 1, a sealed water container 2, a water inlet mechanism 3, a water outlet mechanism 4, and a heat exchange mechanism. The water inlet mechanism 3 includes an inlet Water pipe 31, ball float control valve 32 and water filter 33, the above-mentioned water outlet mechanism 4 includes water outlet pipe 41, water delivery pipe 42 and hot water pump 43, and above-mentioned heat exchange mechanism includes steam exhaust gas collection pipe 51, heat exchanger 52 and sealing water The container steam outlet pipe 53, the heat exchanger 52 includes a conduit 520 and a number of heat exchange blades 521;

[0030] The above-mentioned sealed water container 2 is arranged in the housing 1, the inner surface of the above-mentioned housing 1 is provided with a layer of thermal insulation layer 10, and the outer surface of the above-mentioned seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com