Concrete crack water plugging device and concrete crack water plugging method

A technology for concrete and cracks, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve the problems of difficult pumping of cement slurry, re-seepage of cracks, time-consuming and labor-intensive drilling, etc. The degree of water blocking is deep and the effect of high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

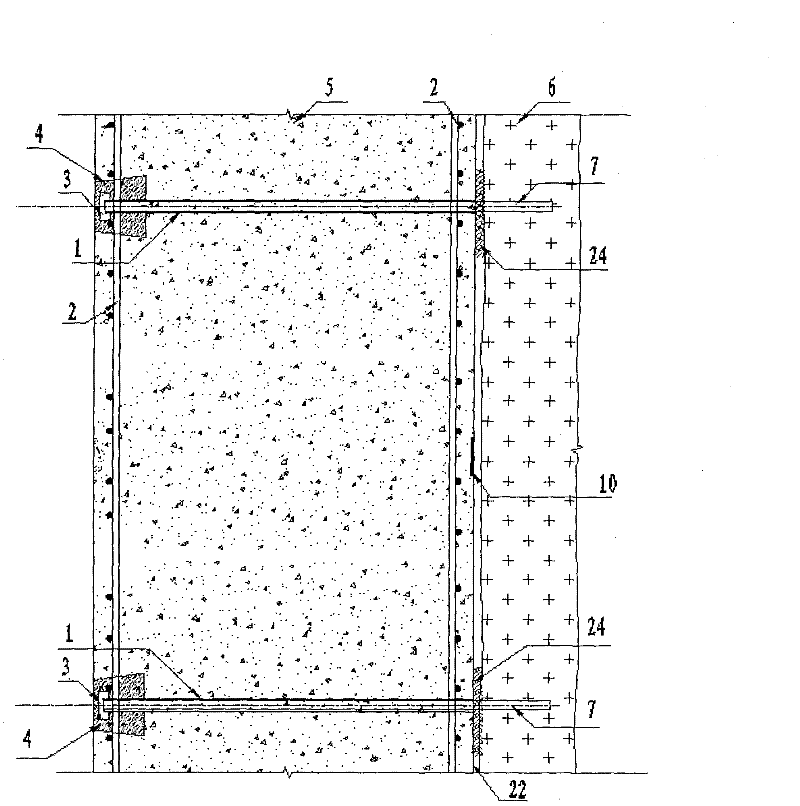

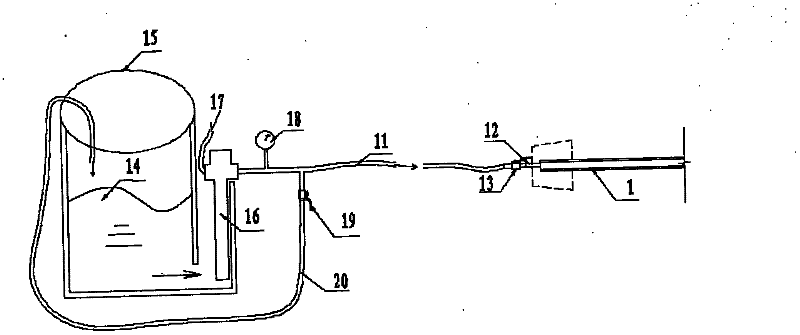

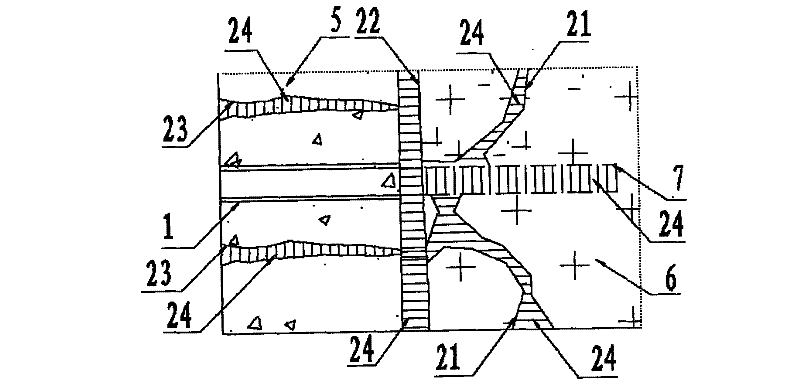

[0031] Please refer to figure 1 , The concrete crack water plugging device of the present invention includes a horizontally arranged grouting pipe 1 , and the grouting pipe 1 runs through the concrete 5 . The length of the grouting pipe 1 is the vertical distance from the surface of the concrete 5 to the rock face. In this embodiment, the outer diameter of the grouting pipe is 48mm and the wall thickness is 3mm. One end of the grouting pipe 1 has a screw thread, and a detachable end cap 3 is installed. After the grouting pipe 1 is fixed, the end cap 3 is tightened to prevent the concrete 5 from entering the grouting pipe during the pouring of the concrete 5 1. Block the grouting pipe 1. One end of the grouting pipe 1 provided with the cap 3 is also provided with a pre-embedded wooden box 4 , and one end of the grouting pipe 1 provided with the cap 3 is acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com