Preparation method of antifouling material having crossed regular microstructure on surface

A microstructure, cross-shaped technology, applied in antifouling/underwater coatings, photoengraving process of patterned surface, optomechanical equipment, etc. Point reduction, the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Preparation of cross-shaped microstructure material

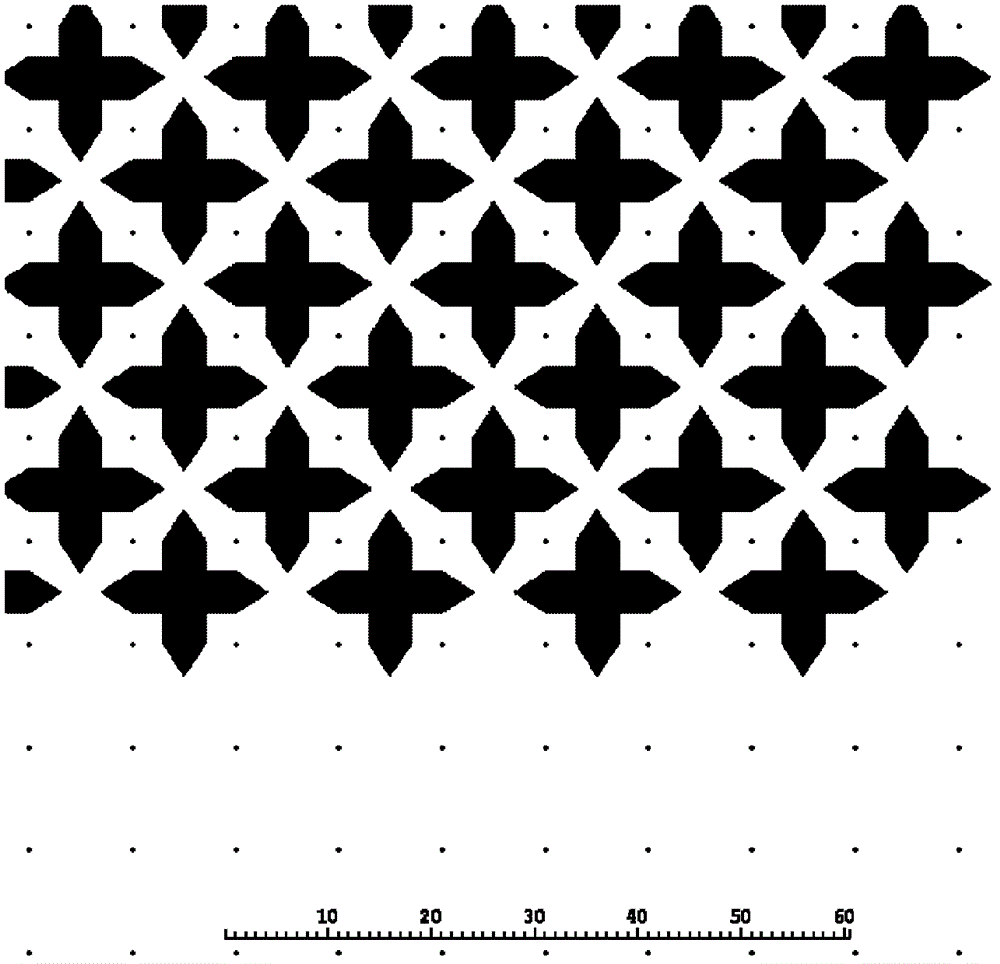

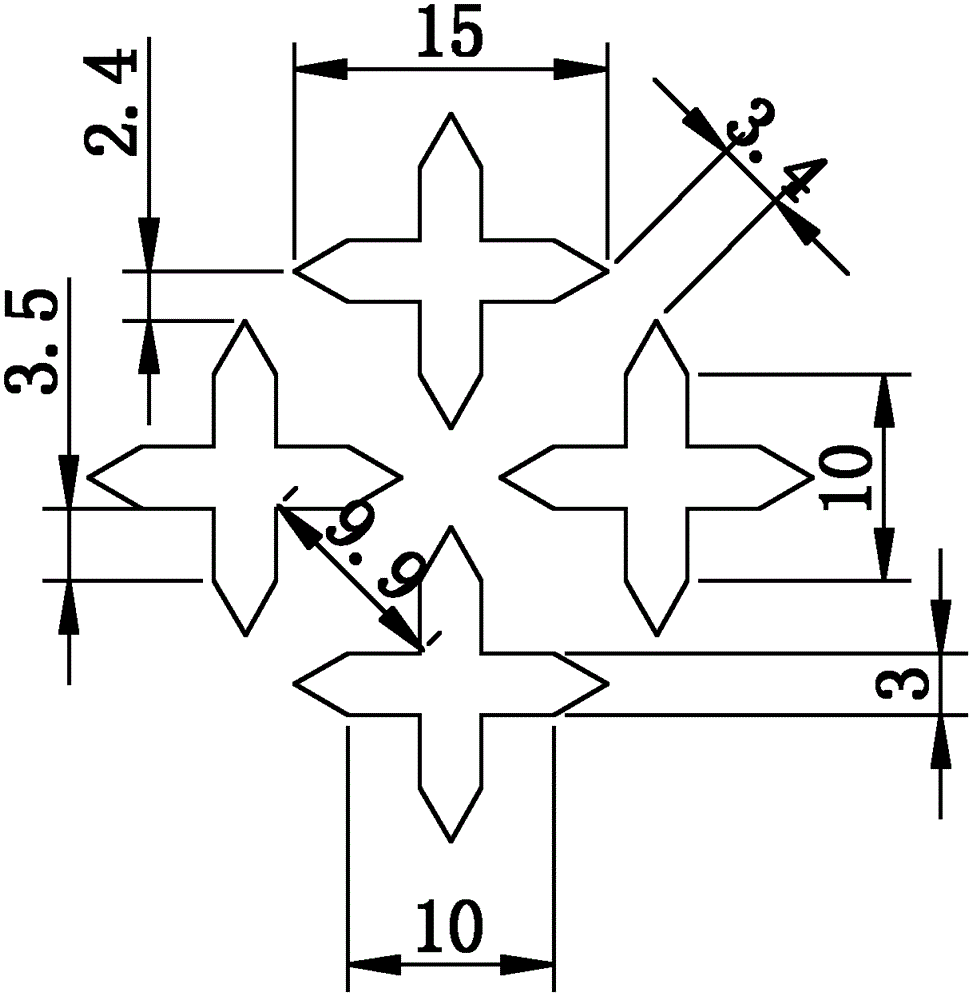

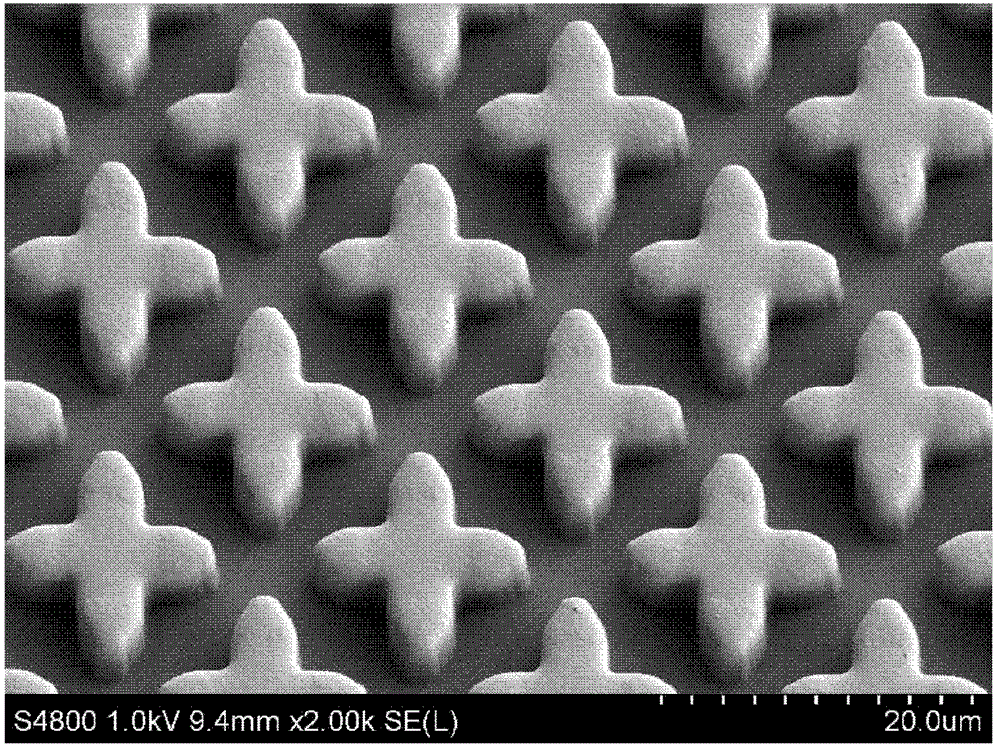

[0017] Prepared by electron beam etching with figure 1 The photomask of the pattern shown, the microstructure arrangement is as follows figure 1 , which is a top view directly above the surface of the material, figure 1 Medium scale bars are in microns. A microstructure with a cross-shaped pattern is etched. The basic units are cross-column-shaped and arranged staggered to form an array. The longest point of the cross is 15 microns, the width of the cross is 3 microns, and the distance between the basic units is 3.4 microns. The specific dimensions are as follows: figure 2 As shown, the unit of the scale in the figure is micron; then the silicon wafer is etched by the deep silicon etching method, etched to a depth of 20 microns in 40 minutes, and a silicon wafer with a depth of 20 microns and a cross-shaped concave pattern can be prepared. Scanning electron microscope photographs of the microstructu...

Embodiment 2

[0020] Prepared by electron beam etching with figure 1 The photomask of the pattern shown, the microstructure arrangement is as follows figure 1 , which is a top view directly above the surface of the material, figure 1 Medium scale bars are in microns. A microstructure with a cross-shaped pattern is etched. The basic units are cross-column-shaped and arranged staggered to form an array. The longest point of the cross is 15 microns, the width of the cross is 3 microns, and the distance between the basic units is 3.4 microns. The specific dimensions are as follows: figure 2 As shown, the unit of the scale in the figure is micron; then the silicon wafer is etched by the deep silicon etching method, and the etching depth is 5 microns in 10 minutes, and a silicon wafer with a depth of 5 microns and a cross-shaped concave pattern can be prepared. Scanning electron microscope photographs of the microstructure image 3 shown.

[0021] Then, take 20g of polydimethylsiloxane and p...

Embodiment 3

[0022] Embodiment 3: the surface contact angle measurement of cruciform microstructure material

[0023] The static contact angles of the polydimethylsiloxane material with a cross-shaped regular microstructure and the polydimethylsiloxane material without microstructure prepared in Example 1 were measured with a static contact angle measuring instrument. It was measured that the static contact angle of the polydimethylsiloxane material without microstructure was 111.9°, and the static contact angle of the polydimethylsiloxane material with cross-shaped microstructure prepared in Example 1 was 140.7°. The existence of the surface microstructure significantly improves the hydrophobicity of the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com