Low-carbon tourmalinite modified asphalt and preparation method thereof

A technology of modified asphalt and tourmaline, which is applied in climate change adaptation, building components, building insulation materials, etc., and can solve the problems of high pollution performance, imperfection, high energy consumption of modified asphalt hot mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

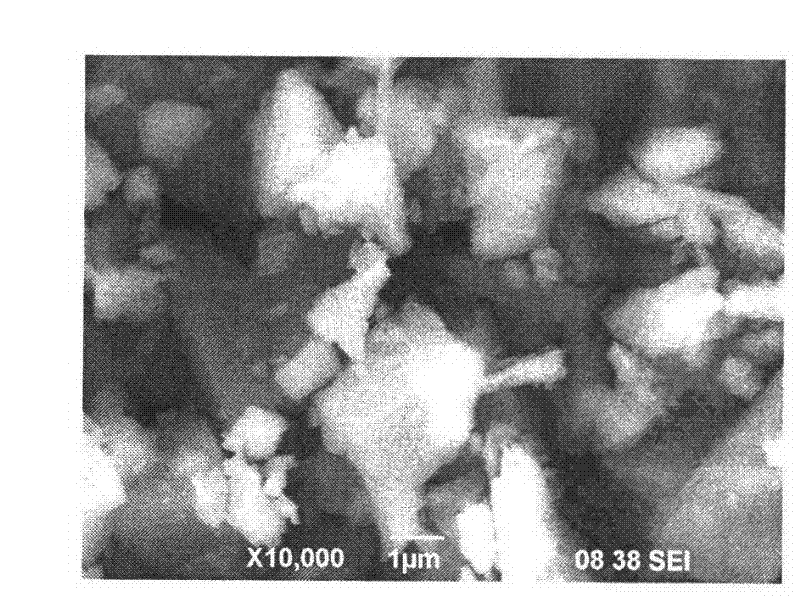

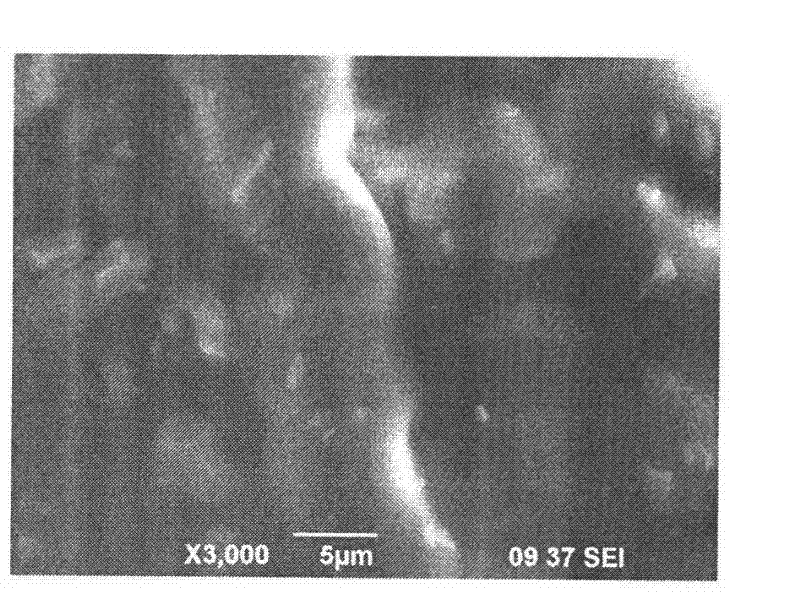

Image

Examples

Embodiment 1

[0035] Taking the production of the product of the present invention with matrix asphalt 100kg as an example, other raw materials used and their mass proportions are:

[0036] Korea SK70# asphalt 100kg

[0037] Tourmaline Negative Ion Powder with Negative Ion Release 5000ions 17kg

[0038] Sodium polyphosphate 0.51kg

[0039] The mass parts proportioning of above-mentioned raw material is:

[0040] Korea SK70# asphalt 100 parts

[0041] Tourmaline Negative Ion Powder with Negative Ion Release 5000ions 17 parts

[0042] Sodium polyphosphate 0.51 parts

[0043] Its preparation method is as follows:

[0044] Heat the base asphalt to 150±5°C, slowly add dry tourmaline negative ion powder to the base asphalt in batches, add sodium polyphosphate, stir manually for 5 minutes at a constant speed, and use a high-speed shearer to stir at 1000 rpm 10 minutes, 4000 rev / min stirring for 30 minutes, 1000 rev / min stirring for 10 minutes, to get rid of air bubbles generated during high-...

Embodiment 2

[0046] Taking the production of the product of the present invention with matrix asphalt 100kg as an example, other raw materials used and their mass proportions are:

[0047] Korea SK70# asphalt 100kg

[0048] Tourmaline negative ion powder with negative ion release 5000ions 20kg

[0049] Sodium polyphosphate 0.6kg

[0050] The proportioning by weight of above-mentioned raw material is:

[0051] Korea SK70# asphalt 100 parts

[0052] 20 parts of tourmaline negative ion powder with negative ion release capacity of 5000ions

[0053] Sodium polyphosphate 0.6 parts

[0054] Its preparation method is identical with embodiment 1.

Embodiment 3

[0056] Taking the production of the product of the present invention with matrix asphalt 100kg as an example, other raw materials used and their mass proportions are:

[0057] Korea SK70# asphalt 100kg

[0058] Tourmaline Negative Ion Powder with Negative Ion Release 5000ions 14kg

[0059] Dispersant 0.42kg

[0060] The proportioning by weight of above-mentioned raw material is:

[0061] Korea SK70# asphalt 100 parts

[0062] Tourmaline Negative Ion Powder with Negative Ion Release 5000ions 14 parts

[0063] Sodium polyphosphate 0.42 parts

[0064] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com