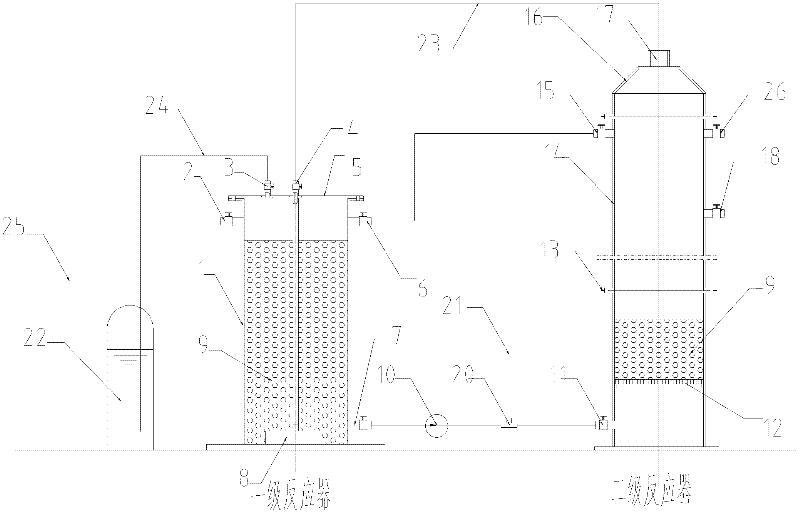

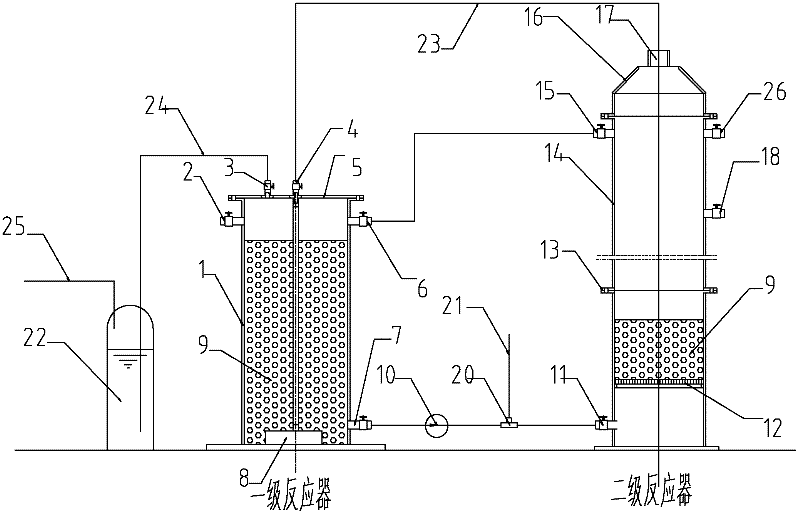

Device and method for treating pulping wastewater by catalyst and ozone

A technology for pulping wastewater and ozone treatment, which is applied in chemical instruments and methods, oxidized water/sewage treatment, processing wastewater treatment, etc. problems, to achieve the effect of improving the oxidative degradation effect, improving the degradation and removal effect, and convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The device and method provided by the present invention are used to treat the secondary biological treatment effluent of the wastewater in the middle stage of pulping, the water temperature is 30°C, and the COD cr It is 319~350mg / L, and the chromaticity is 470C.U..

[0048] Activated carbon supported manganese oxide is used as a catalyst, and the mass of the manganese oxide is 10% (wt, %) of the activated carbon. The aqueous solution of manganese acetate was mixed with activated carbon, shaken at 300 rpm and 30°C for 2 hours, evaporated to dryness at 60°C, then dried, incinerated at 600°C for 3 hours, cooled and sieved to obtain the catalyst.

[0049] The effluent flow rate of secondary biological treatment of pulping wastewater is 2.5L / min, the pH value is 8, the gas flow rate in the ozone pipe is 1L / min, the ozone concentration is 40mg / L, and the treated wastewater COD cr The removal rate is 63.9%, the chroma removal rate is 95%, the COD of wastewater cr The removal...

Embodiment 2

[0052] The device and method provided by the present invention are used to treat the secondary biological treatment effluent of the wastewater in the middle stage of pulping, the water temperature is 30°C, and the COD cr It is 319~350mg / L, and the chromaticity is 470C.U..

[0053] Titanium oxide supported on activated carbon is used as a catalyst, and the mass of titanium oxide is 5% (wt, %) of the activated carbon. Mix the aqueous solution of titanium sulfate with activated carbon, vibrate at 200 rpm and 20°C for 2 hours, evaporate to dryness at 50°C, then dry, incinerate at 400°C for 5 hours, cool and sieve to obtain the catalyst.

[0054] The effluent flow rate of the secondary biological treatment of pulping wastewater is 2.5L / min, the pH value is 9, the gas flow rate in the ozone pipe is 1L / min, and the ozone concentration is 40mg / L. The result is that the wastewater COD cr The removal rate is 65.8%, the chroma removal rate is 96%, the COD of wastewater cr The removal r...

Embodiment 3

[0056] The device and method provided by the present invention are used to treat the secondary biological treatment effluent of the wastewater in the middle stage of pulping, the water temperature is 30°C, and the COD cr It is 319~350mg / L, and the chromaticity is 470C.U..

[0057] Active carbon supported manganese oxide and nickel oxide are used as catalysts, and the quality of manganese oxide and nickel oxide is 10% (wt, %) of the active carbon. After mixing the aqueous solution of manganese acetate and nickel nitrate with active carbon, shake at 100rpm and 30°C Evaporate to dryness at 60°C for 2 hours, then dry, incinerate at 500°C for 4 hours, cool and sieve to obtain the catalyst.

[0058] The effluent flow rate of secondary biological treatment of pulping wastewater is 2.5L / min, the pH value is 10, the gas flow rate in the ozone pipe is 1L / min, and the ozone concentration is 40mg / L. The result is that the wastewater COD cr The removal rate is 71.4%, the chroma removal ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com