Full-automatic wide grinding wheel roller grinding machine

A roller grinding machine, fully automatic technology, applied in the field of textile machinery, can solve the problems of product geometric tolerance and roughness not meeting the requirements, the quality of the rollers not meeting the requirements, increasing the waste of labor resources, etc., to save grinding Time, improve grinding efficiency, improve the effect of grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

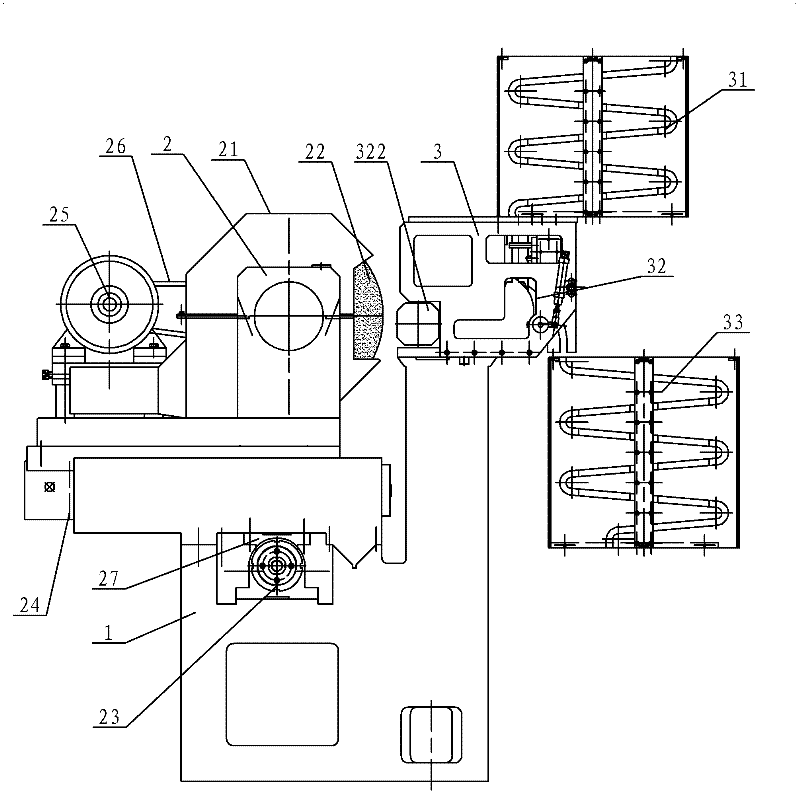

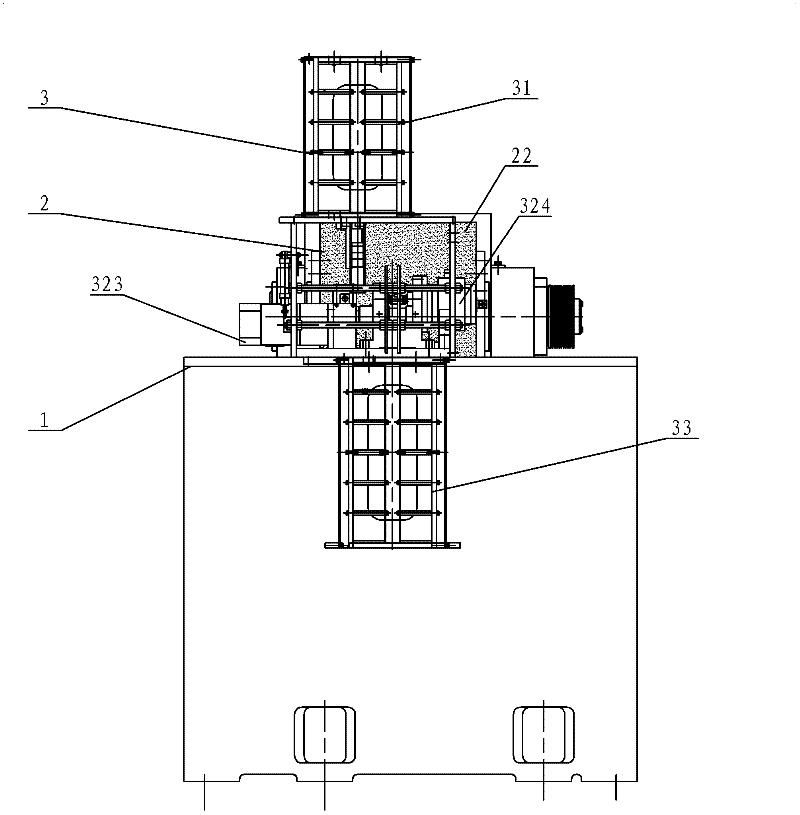

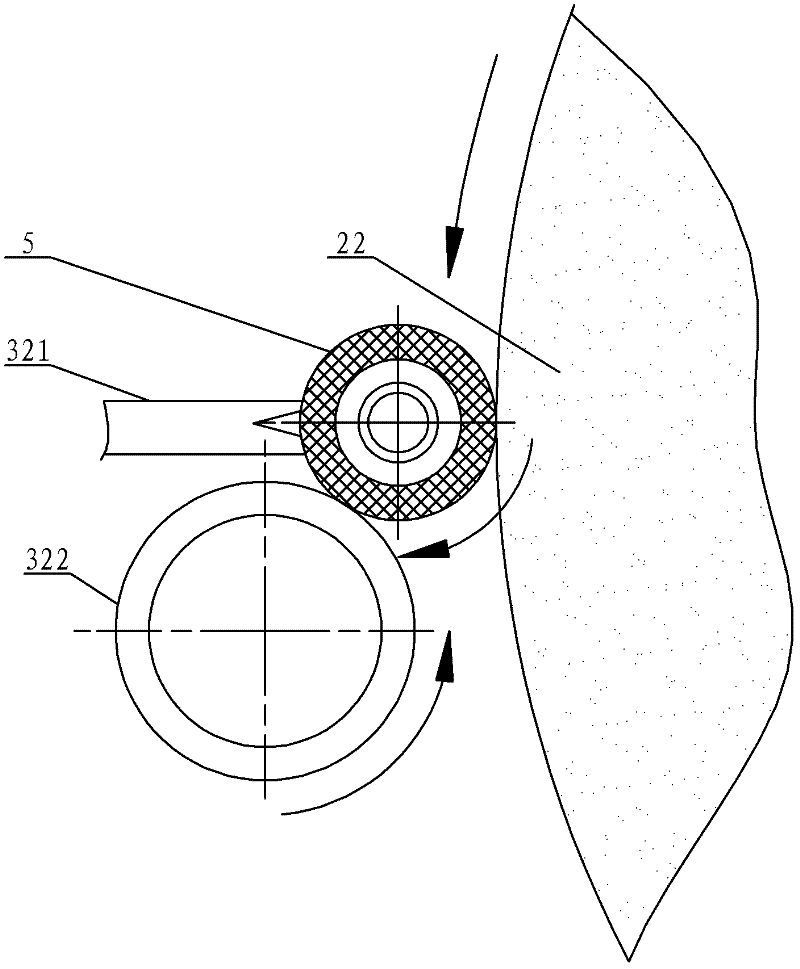

[0018] like Figure 1~3 In the shown embodiment, the fully automatic wide grinding wheel roller grinding machine according to the present invention includes a bed 1, a grinding device 2, an automatic loading and unloading device 3 and a system control device 4, and the upper side of the bed 1 is provided with a grinding machine. Device 2, the other side is provided with an automatic loading and unloading device 3, the grinding device 2 includes a grinding wheel seat 21, the bottom of the grinding wheel seat 21 is provided with a base 27, and the bottom of the base 27 and the inside of the bed 1 are provided so that the base 27 can move back and forth along the Z axis Servo motor a 23, the servo motor b24 that can make the grinding wheel base 21 move back and forth along the X axis is set between the base 27 and the grinding wheel base 21, the grinding wheel 22 is arranged between the grinding wheel bases 21, and one side of the grinding wheel 22 is set so that the grinding whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com