Preparation method for monolithic catalyst sample

A monolithic catalyst, catalyst technology, applied in catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problems that cannot be directly used for the preparation of monolithic catalyst samples, lack of technology, etc., to shorten the research and development cycle, size Accurate control and the effect of reducing R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

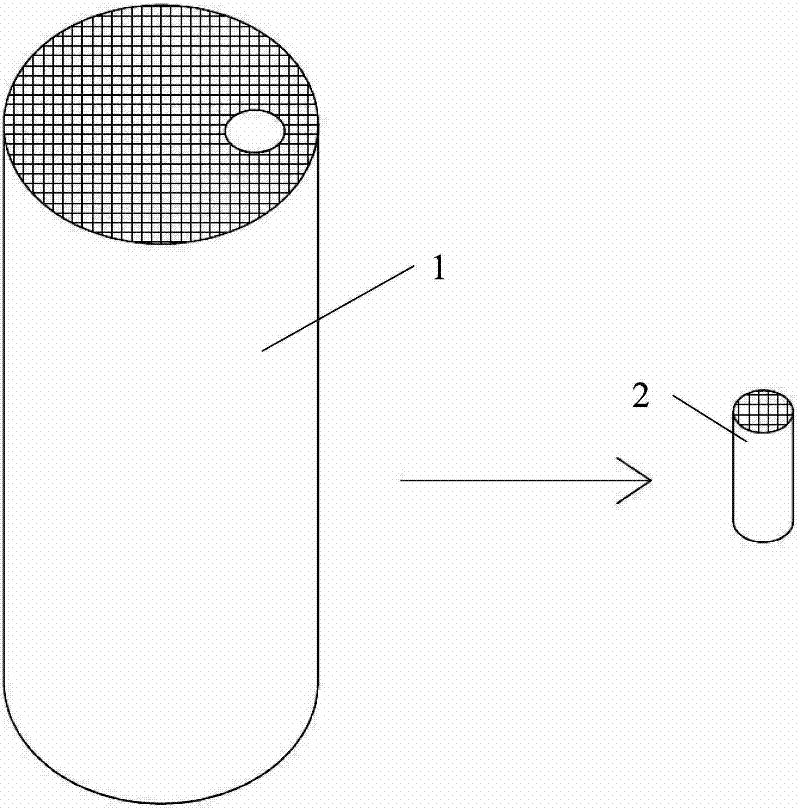

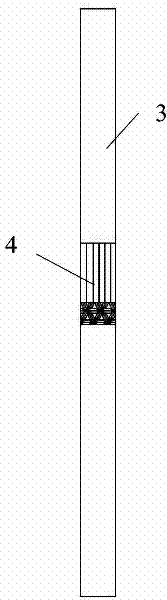

Embodiment 1

[0026] The total flow rate of reaction gas is 300 mL / min, and the control space velocity is required to be 15000 h -1 , so the required volume of the honeycomb ceramic carrier is 1.2 mL. The inner diameter of the fixed-bed reactor is 7 mm, and the diameter and length of the honeycomb ceramic carrier are 7 mm and 31 mm, respectively. Therefore, diamond drill bits with inner diameter and length of 7mm and 35mm were selected. The size of the purchased cylindrical cordierite honeycomb ceramics is φ101.91*123.26mm. A certain number of small cylinders were drilled on the cordierite honeycomb ceramics, and then cut with a cutting machine to a length of 31 mm. Finally, they were rinsed with deionized water, dried at 110 °C for 4 h, and then placed in a muffle furnace with 2°C / min programmed temperature rise to 550°C for 2 h. The process of drilling a small-volume honeycomb ceramic carrier from a honeycomb ceramic carrier is as follows: figure 1 as shown, figure 1 1 in it is a hon...

Embodiment 2

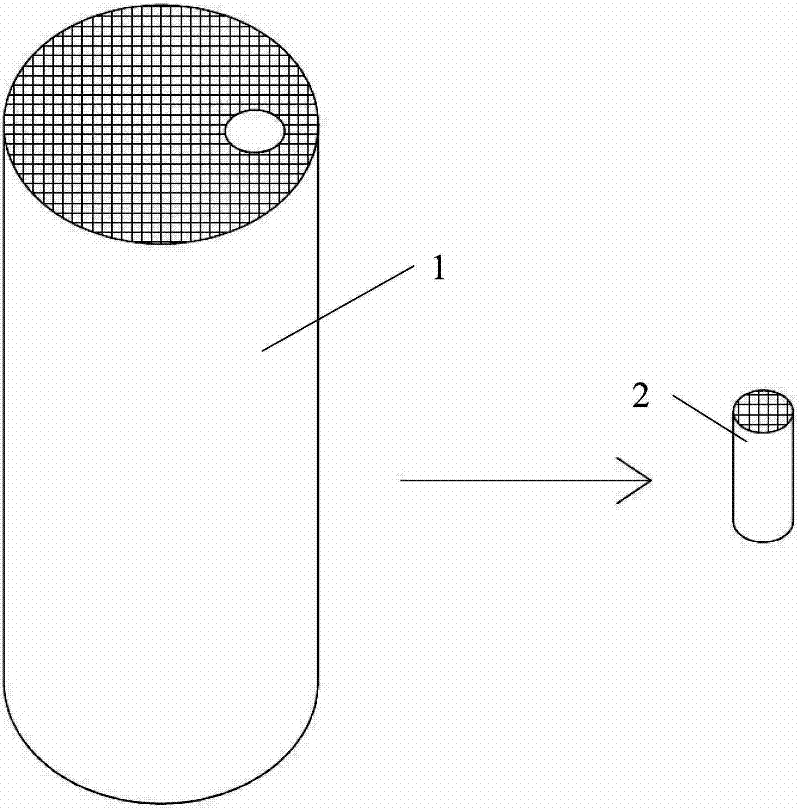

[0030] The total flow rate of reaction gas is 300 mL / min, and the control space velocity is required to be 15000 h -1 , so the required volume of the honeycomb ceramic carrier is 1.2 mL. The inner diameter of the fixed-bed reactor is 9 mm, and the diameter and length of the honeycomb ceramic carrier are 9 mm and 19 mm, respectively. Therefore, diamond drill bits with inner diameter and length of 9 mm and 35 mm were selected. The size of the purchased cylindrical cordierite honeycomb ceramics is φ117.39*151.25mm. A certain number of small cylinders were drilled on the cordierite honeycomb ceramics, and then cut with a cutting machine to a length of 19 mm. Finally, they were rinsed with deionized water, dried at 110 °C for 4 h, and then placed in a muffle furnace with 2°C / min programmed temperature rise to 550°C for 2 h.

[0031] Weigh the calcined small-volume honeycomb ceramic carrier; immerse it in the catalyst coating solution, take it out slowly after 5 min, dry the resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com