Self-locking wire end earthing clamp

A technology of grounding clips and wire ends, applied in the direction of conductive connection, connection, electrical component connection, etc., can solve the problems of difficult operation, loss of protection, low efficiency, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

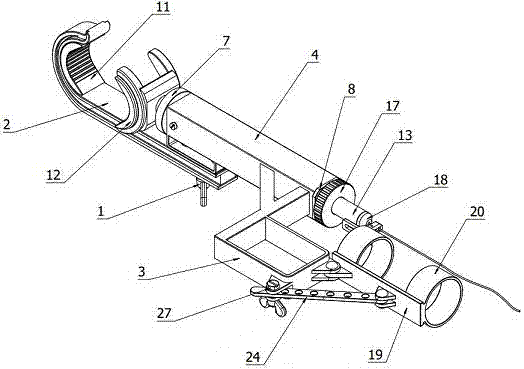

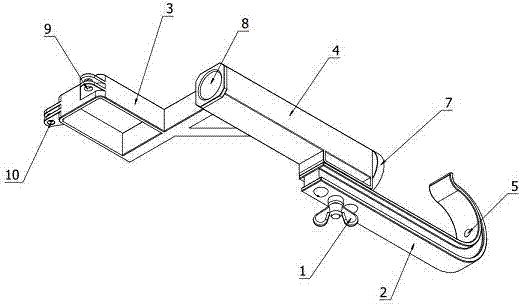

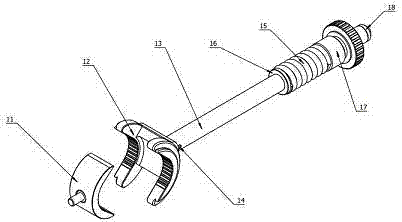

[0017] Such as Figure 1 to Figure 7 As shown, the self-locking wire end grounding clamp of the present invention includes a clamp main body, a secondary clamp and an angle adjustment mechanism. One end of the clamp main body is the main wire chuck 2, the other end is a bracket 3, and the middle is connected by a clamp body 4. The bottom of the main line chuck 2 is provided with a ground wire connector 1, the main line chuck 2 and the clamp body 4 are fixedly connected by rivets, the clamp body 4 is a tubular structure with two ends open, and the clamp body 4 is fixedly installed with a guide tube near the end of the main line chuck 2 7. The other end of the clip body 4 is fixed with a threaded pipe 8, the bracket 3 is fixed on the side of the clip body 4, and the bracket 3 is provided with a first hinge joint 9 and a second hinge joint 10; the auxiliary line clamp includes a fixed half clamp The head 11 and the movable half chuck 12, the fixed half chuck 11 is inserted into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com