Five-port capacitance type microwave power sensor based on micro mechanical clamped beam

A technology of microwave power and fixed beams, which is applied in the direction of electric power measurement by thermal method, electric solid devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

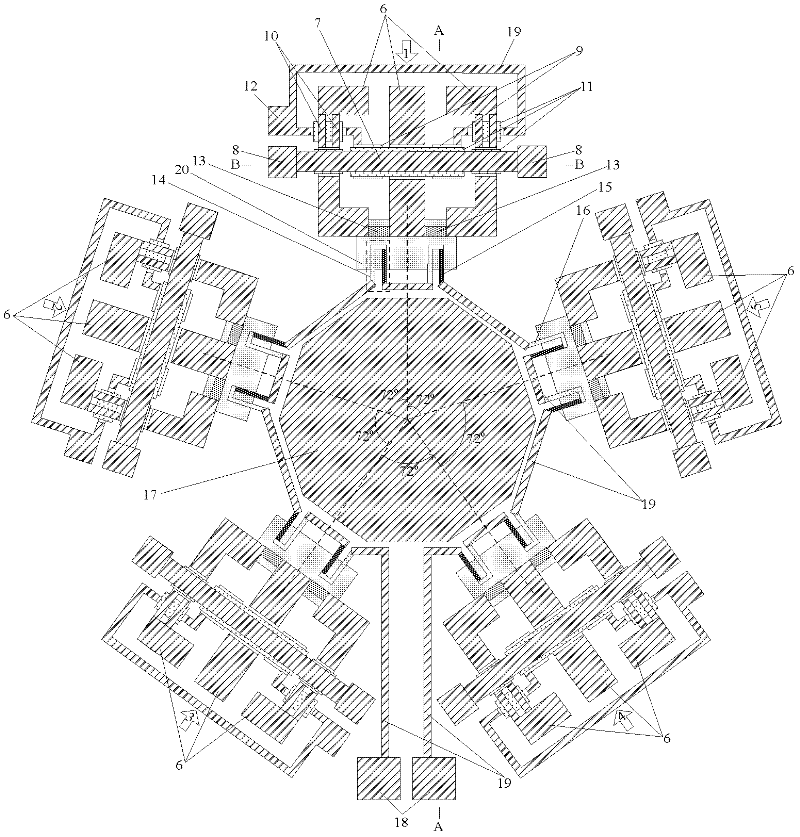

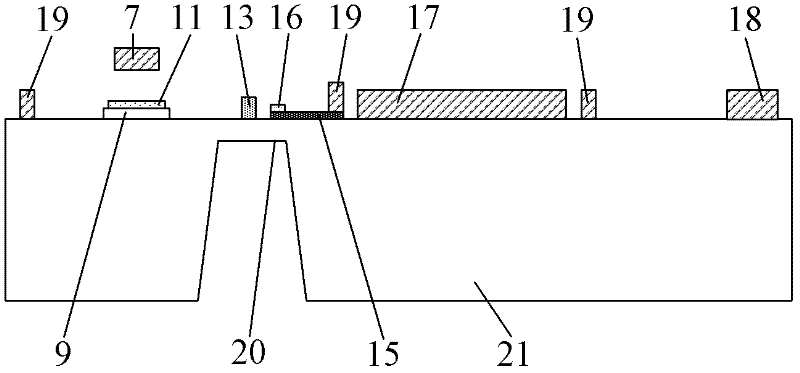

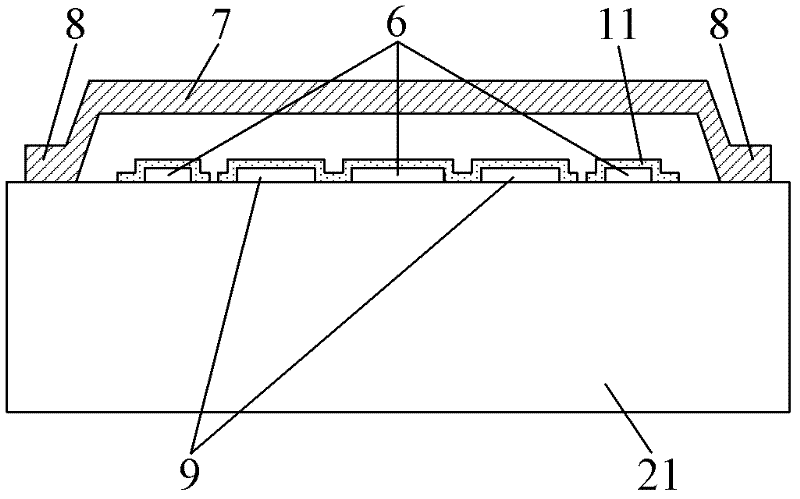

[0045] The specific implementation scheme of the five-port capacitive microwave power sensor based on micro-mechanical fixed beams invented in this paper is as follows:

[0046] Five CPWs 6, five MEMS fixed beams 7, anchor regions 8 of the fixed beams, sensing electrodes 9, pressure soldering blocks 12 of the sensing electrodes, and ten terminal matching resistors are arranged on the gallium arsenide substrate 21 13. A thermopile consisting of five pairs of thermocouples 14 composed of ten thermocouples 14, two output pressure welding blocks 18, a metal heat sink 17, air bridge 10 and connecting wires 19, forming a thermopile under the substrate 21 MEMS substrate film structure 20:

[0047] The CPW 6 is used to realize the transmission of the microwave signal, and the circuit connection between the test instrument and the terminal matching resistor 13 . Each CPW 6 consists of a CPW signal line and two ground lines.

[0048] The five MEMS fixed beams 7 straddle the five symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com