Device for detecting pitch error of acrylonitrile butadiene styrene (ABS) gear ring by magnetic induction

A technology for ABS ring gear and pitch error, which is applied in the field of magnetic induction detection device for ABS ring gear pitch error, can solve the problems that cannot meet the accuracy requirements, small size, difficult to determine the pitch error of the ABS ring gear to be tested, etc. Achieve the effects of improving credibility and reliability, reducing test time, and reducing the risk of manual counting errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

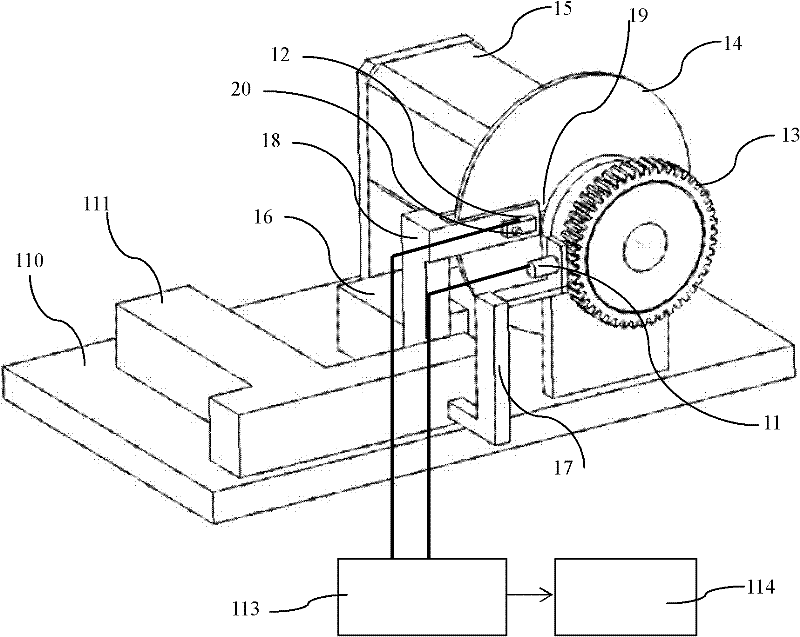

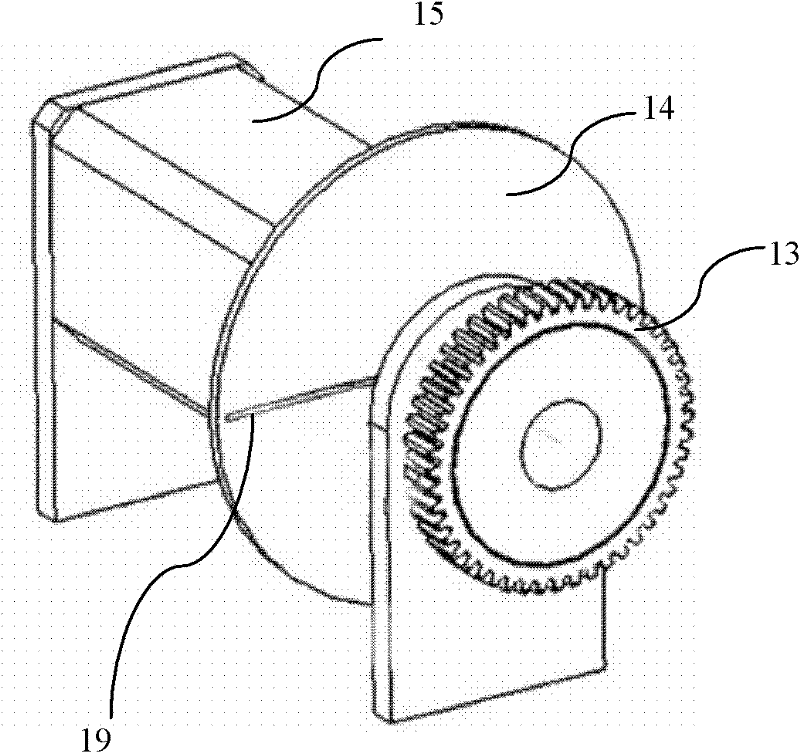

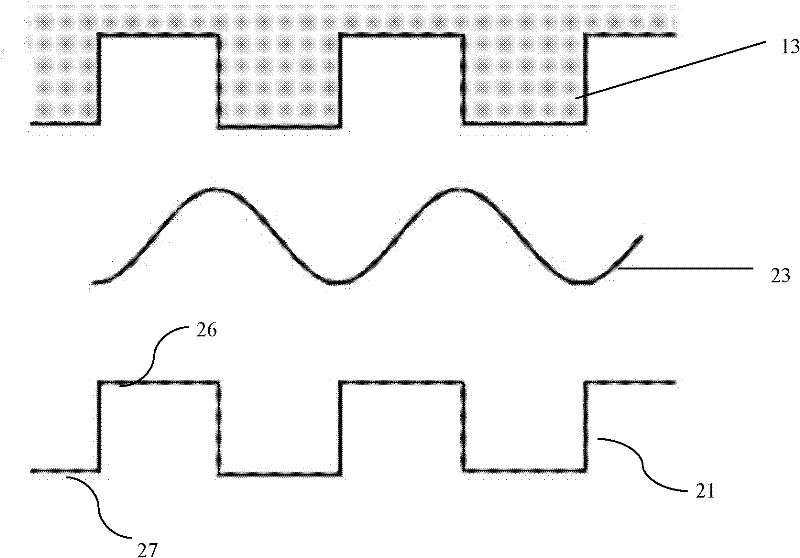

[0034] Such as figure 1 , figure 2 As shown, the detection device in the present invention includes a motor 15, and the motor 15 is provided with an output shaft (not shown in the figure) for outputting rotational driving force. Positioning wheel 14 is installed on the output shaft of motor 15. The positioning wheel 14 is provided with a through groove 19 . For the ABS ring gear 13 to be tested, it is necessary to detect its pitch single-tooth error, cumulative error and out-of-tolerance tooth position. The ABS ring gear 13 to be tested is mounted on the output shaft of the motor 15 and rotates synchronously with the positioning wheel 14 . The Hall-type magnetic induction sensor 11 is installed on the second bracket 17 . The photoelectric sensor 12 is installed on the first bracket 18 . The first bracket 18 is installed on the first adjustable bracket 16 . The first ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com