Automatic testing equipment and method for l3-layer circuit board

A technology of automated test and circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

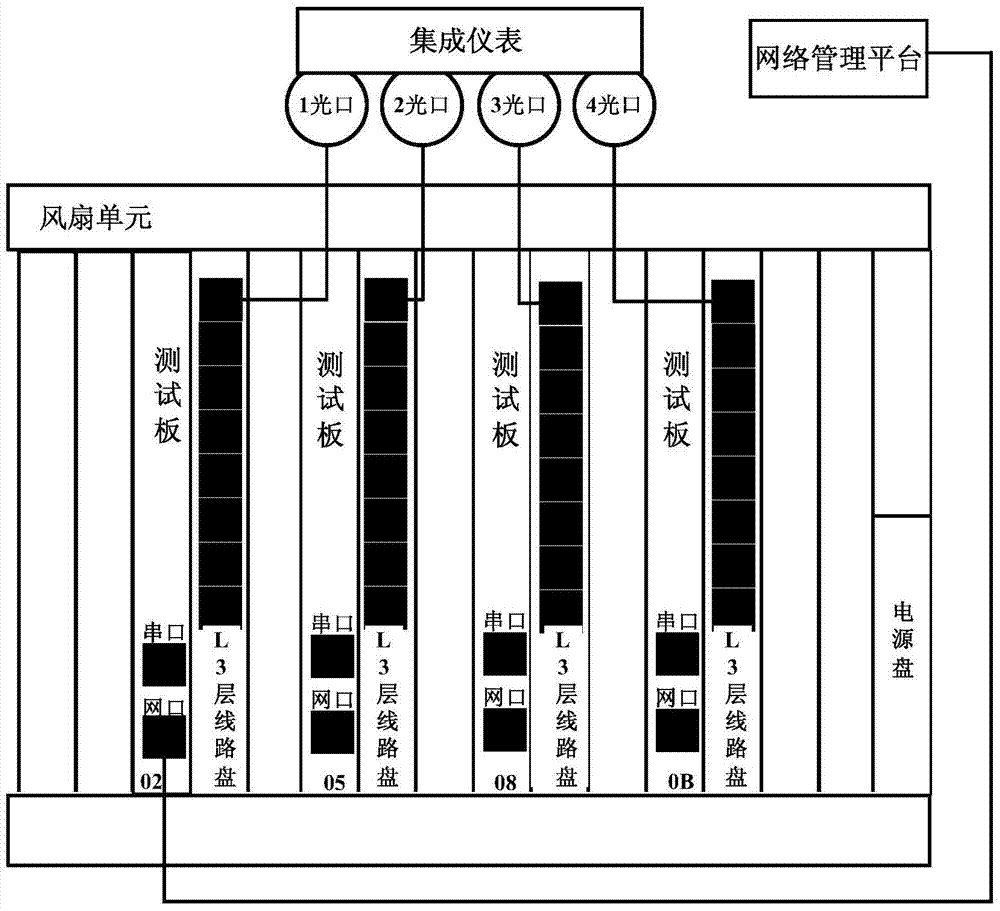

[0043] see figure 1 As shown, the automated testing equipment for the L3 layer line disk in the embodiment of the present invention includes a test subrack, a network management platform (computer) and an integrated instrument for connecting with the optical port of the L3 layer line disk; the test subrack It includes several test boards. Each test board has a serial port, a network port and an L3 layer circuit board installation slot. All the test boards are connected to each other through their respective serial ports, and the network port of any test board is connected to the network management platform.

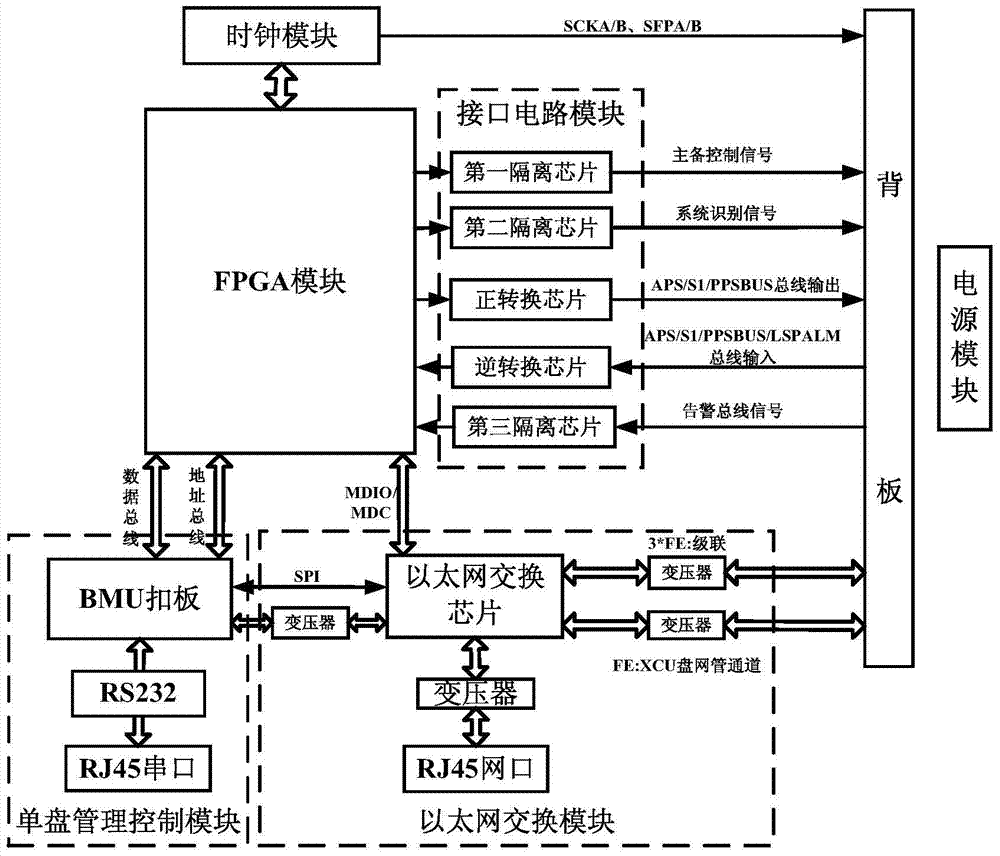

[0044] There are automated test units inside the test subrack, see figure 2 As shown, the automated test unit includes a power supply module, a clock module, an FPGA (Field-Programmable Gate Array, Field Programmable Gate Array) module,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com