Waste heat utilization device for solar photovoltaic power generation

A solar photovoltaic and photovoltaic power generation technology, applied in solar thermal devices, solar thermal power generation, photovoltaic power generation, etc., can solve the problems of easy freezing, affecting the service life of photovoltaic power generation components, and short circuit of batteries due to moisture, so as to reduce the surface temperature, control the The effect of heat dissipation and sufficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

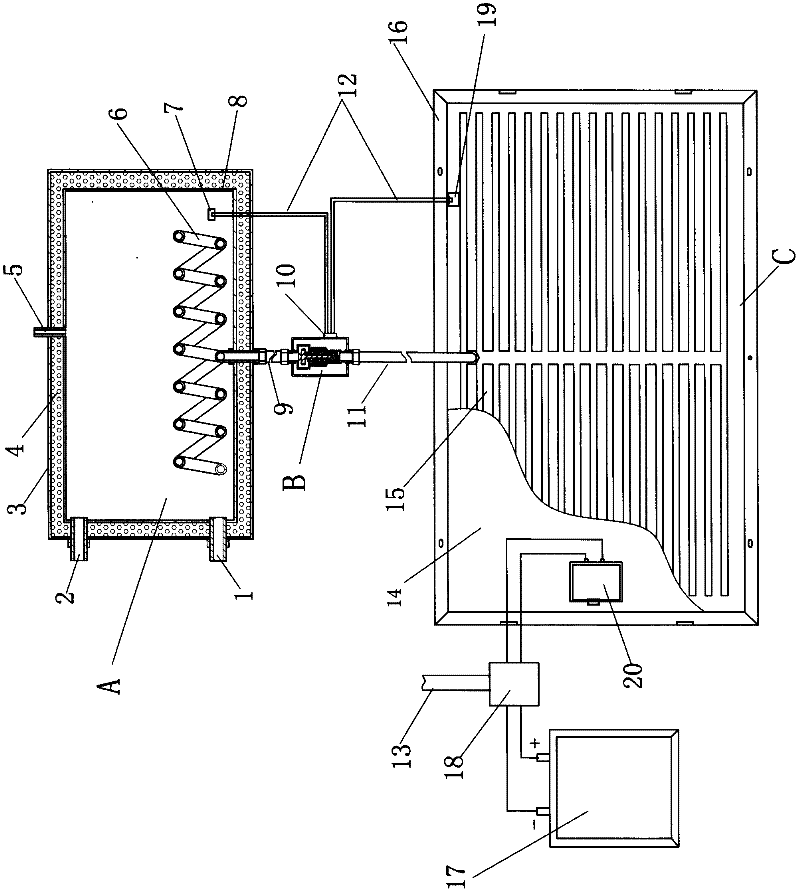

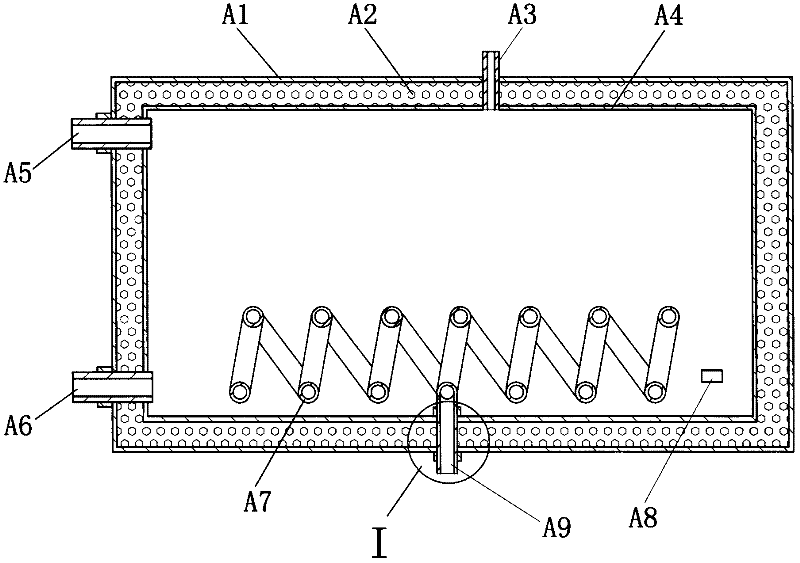

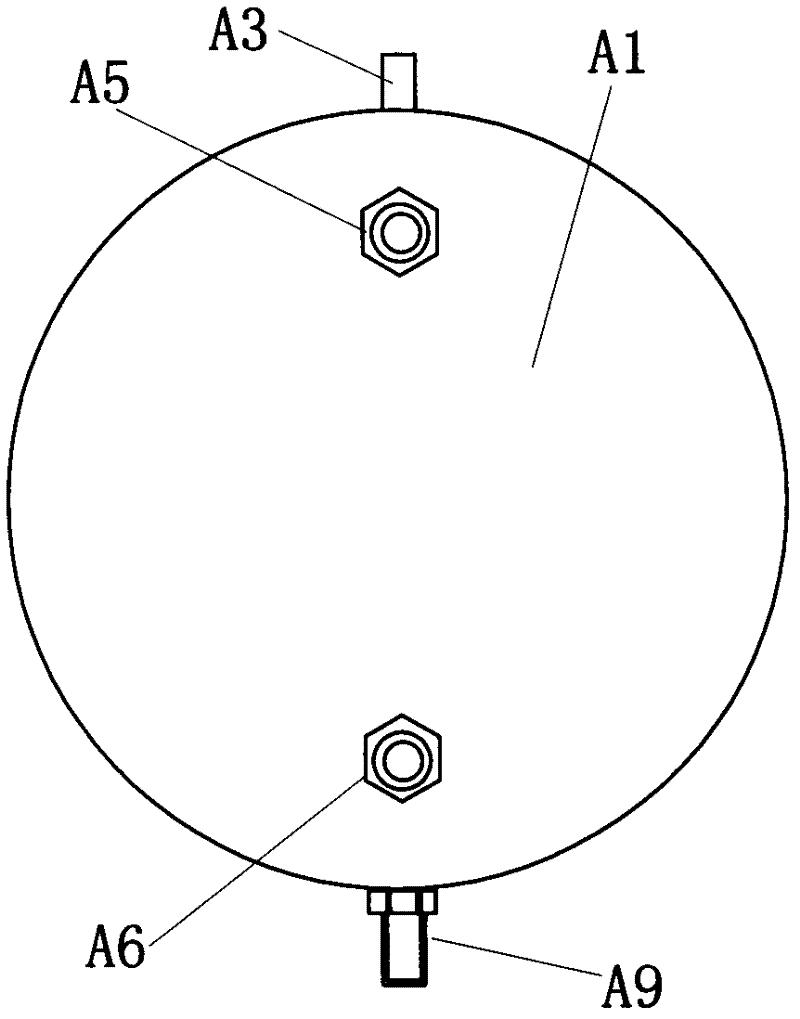

[0030] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0031] This device uses existing conventional polysilicon or monocrystalline silicon photovoltaic power generation components to install a comb-type heat energy harvester on the back plate according to the size (see the schematic diagram of the comb-type heat energy harvester in the attached drawing), and the heat energy obtained by the collector is transferred to the single The heat conduction valve is transferred to the spiral heat exchanger and water for heat energy exchange through the one-way valve, and finally the heat energy is stored in the heat energy storage to supply hot water. The microprocessor in the one-way heat conduction valve makes a logical judgment on the heat-sensitive signal from the comb-type thermal energy harvester and the heat-sensitive signal from the thermal energy storage. If the temperature of the comb-type heat energy ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com