Anti-seismic structure of energy-consumption angle brace

An earthquake-resistant structure and corner bracing technology, applied in earthquake-proof, building components, building structure, etc., can solve the problems of node damage and inability to resist earthquake disasters, and achieve the effects of protecting nodes, strengthening strength, and enhancing node rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

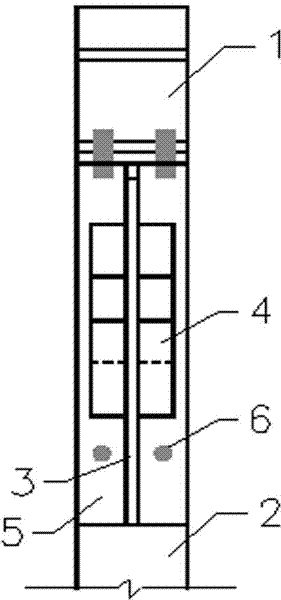

[0018] Such as figure 1 , 2 The shown structure of an embodiment of an energy-dissipating corner brace seismic structure of the present invention includes a frame beam 1 and a frame column 2, and a triangular energy-dissipating corner brace plate 3 is provided at the node position of the frame beam 1 and frame column 2 One end of the triangular energy-dissipating brace plate 3 is in contact with the frame beam 1, and the two are fixedly connected by bolts 6 through the connecting plate 5; the other end of the triangular energy-dissipating brace plate 3 is also connected with the frame column 2 through The connecting plate 5 is fixedly connected by bolts 6 , and a stiffener 4 is provided in the middle of the triangular energy-dissipating corner brace 3 .

Embodiment 2

[0020] Such as image 3 , 4 The structure shown in another embodiment of the seismic structure of an energy-dissipating corner brace of the present invention includes a frame beam 1 and a frame column 2, and trapezoidal energy-dissipating corner braces are arranged at the nodes of the frame beam 1 and frame column 2 3. One end of the trapezoidal energy-dissipating brace 3 is in contact with the frame beam 1, and the two are fixedly connected by bolts 6 through the connecting plate 5; the other end of the trapezoidal energy-dissipating brace 3 is in the same contact surface as the frame column 2 The two are fixedly connected by bolts 6 through the connecting plate 5 , and a stiffening rib 4 is provided at the middle position of the trapezoidal energy-dissipating corner brace 3 .

Embodiment 3

[0022] An anti-seismic structure of an energy-dissipating corner brace according to the present invention comprises a frame beam 1 and a frame column 2, and a triangular energy-dissipating brace plate 3 is arranged at the joint position of the frame beam 1 and the frame column 2; one end of the triangular energy-dissipating brace plate 3 The contact surface with the frame beam 1 is fixedly connected by welding through the connecting plate 5; the other end of the triangular energy-dissipating corner brace 3 and the contact surface of the frame column 2 are also fixedly connected by welding through the connecting plate 5 , A stiffener 4 is provided at the middle position of the triangular energy-dissipating corner brace 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com