Novel yarn guiding wheel

A godet wheel, a new type of technology, applied in the direction of artificial filament support, textiles and papermaking, etc., can solve problems such as unusable, peeling off, affecting spinning accuracy, etc., to improve wear resistance and heat resistance, and service life Long, high-performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

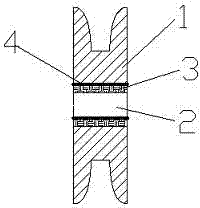

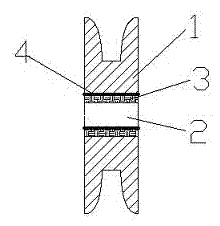

[0016] figure 1 It is a schematic diagram of the structure of the new godet wheel according to the embodiment of the present invention; the godet wheel includes a godet wheel body 1, the middle part of the godet wheel body 1 is provided with a shaft hole 2, and an inner ring is arranged in the shaft hole 2 3. An interference fit is adopted between the shaft hole 2 and the inner ring 3, the godet wheel body 1 is made of high-temperature sintered ceramic material, and the inner ring 3 is made of graphite material.

[0017] The inner ring 3 of the new godet wheel mentioned in the present invention is formed by a molding process, and its raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com