Water-soluble MDI-TMP (Diphenylmethane Diisocyanate-Trimethylolpropane) polyurethane prepolymer

A polyurethane prepolymer and water-soluble technology, which is applied in the chemical field, can solve the problems of great harm to the human body, and achieve the effect of reducing damage and reducing the content of free TDI

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Add 15 parts of ethyl acetate to a reaction kettle filled with nitrogen, then add 30 parts of MDI, raise the temperature to 50°C, stir at the same time until it is completely dissolved, add 15 parts of TMP, and raise the temperature to 70°C, the reaction 4 hours, then add 30 parts of sodium bisulfite, and finally add a small amount of phosphoric acid to adjust the pH to 6.

[0014] After testing, the technical indicators of the obtained MDI-TMP bridging agent are as follows: the appearance is a water-white transparent liquid at room temperature, the solid content is 56%, the viscosity is 1304mPa. s, the -NCO content is 11.0~11.5%, free TDI monomer The content is less than 0.05%.

Embodiment 2~3

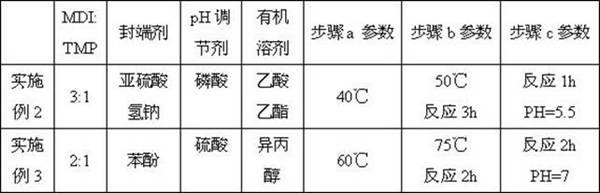

[0016] The preparation process steps of Examples 2-3 are the same as those of Examples, except that the ratio of MDI to TMP added, end-capping agent, pH regulator and reaction parameters are different.

[0017]

[0018]

[0019] Table 1 is the ratio of MDI and TMP added in Examples 2 to 3, end-capping agent, pH regulator and reaction parameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com