Preparation method of coating type natural color sand flexible face brick and construction technology thereof

A technology made of natural colored sand and colored sand, which is applied to the material field in the field of construction technology, can solve the problems of easy ash hanging in the spraying effect, waste of materials, and imperviousness to contamination, etc., and achieves the improvement of construction quality, speed, and restriction requirements. The effect of reducing and avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

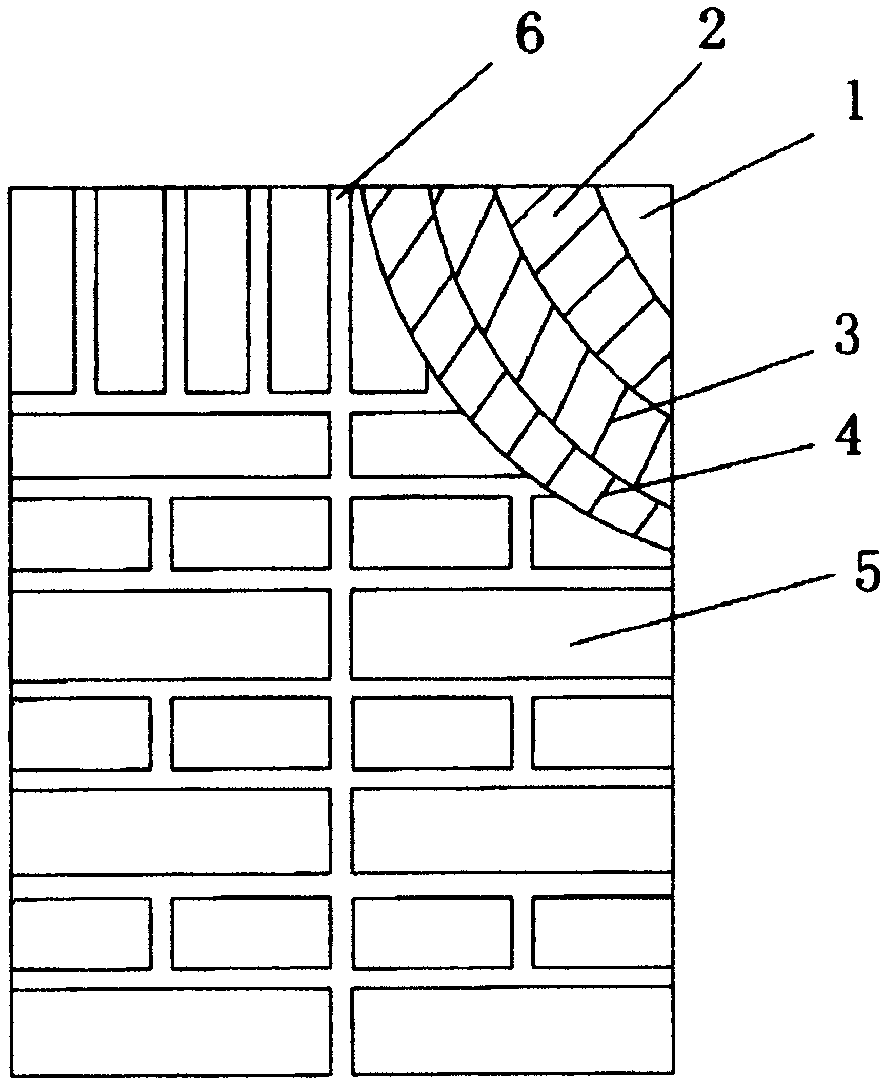

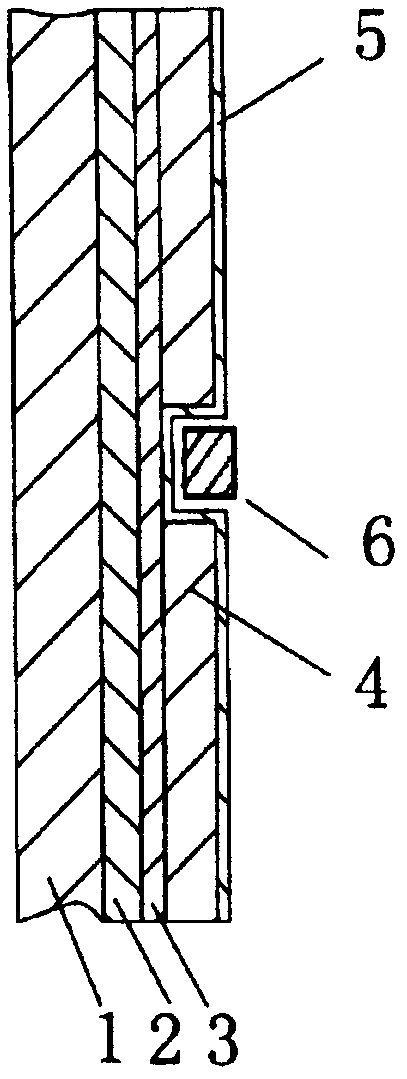

[0041] The present invention is further described below in conjunction with accompanying drawing and specific embodiment:

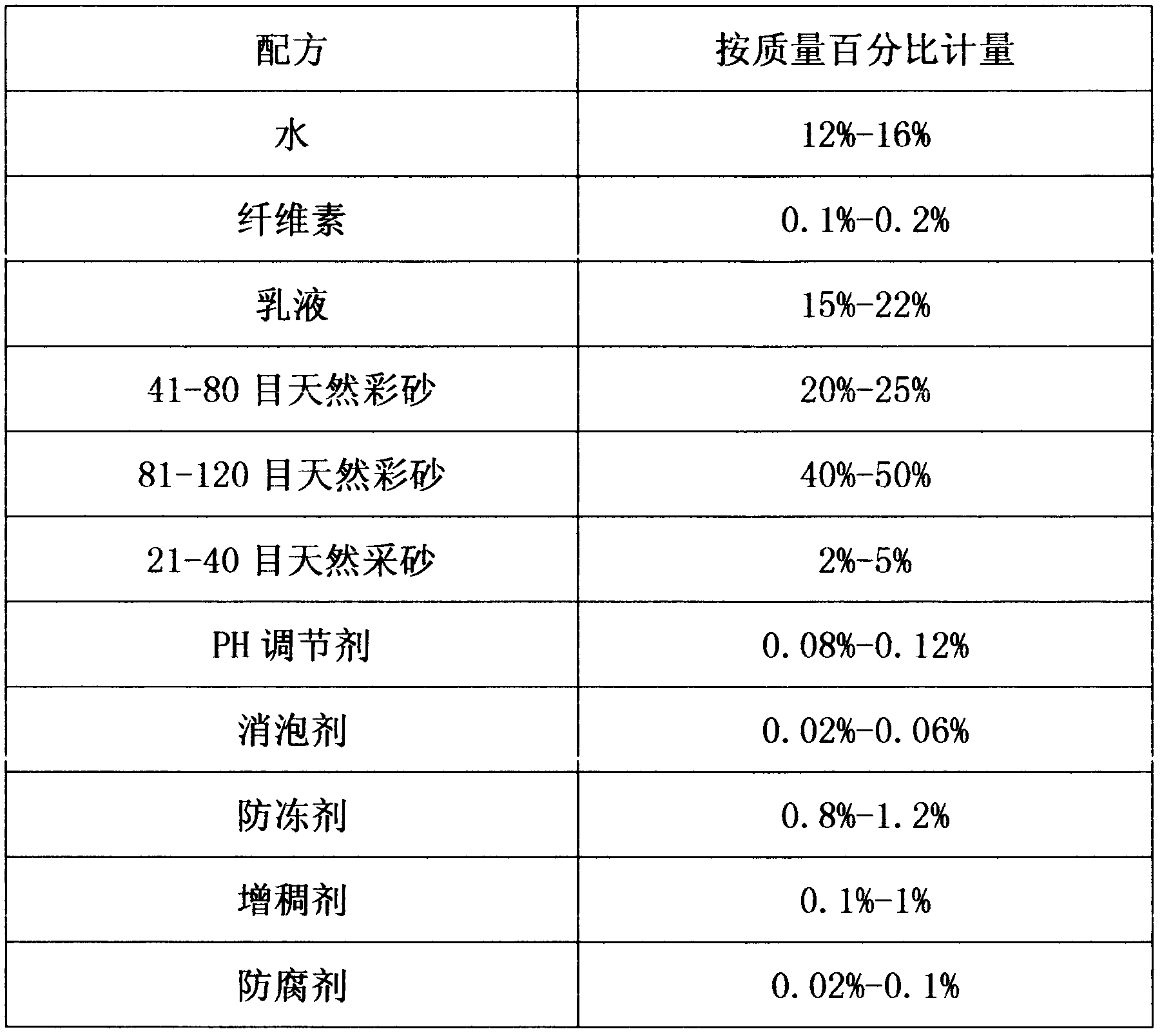

[0042] A batch-coating method for preparing flexible tiles made of natural colored sand, which is prepared by mixing the following components by weight: 12%-16% of water, 0.1%-0.2% of cellulose, 15%-22% of emulsion, 41 -80 mesh natural colored sand 20%-25%, 81-120 mesh natural colored sand 40%-50%, 21-40 mesh natural mining sand 2%-5%, PH regulator 0.08%-0.12%, defoamer 0.02%-0.06%, antifreeze 0.8%-1.2%, thickener 0.1%-1%, preservative 0.02%-0.1%.

[0043] The water is edible pipeline water.

[0044] The cellulose is hydroxyethyl cellulose.

[0045] The emulsion is a pure acrylate polymer emulsion.

[0046] The 41-80 mesh natural colored sand, the 81-120 mesh natural colored sand and the 21-40 mesh natural mining sand are natural colored sand in nature.

[0047] The pH regulator is an organic amine neutralizer, and the model is AMP95.

[0048] Descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com