System and method for treating oil-containing sludge

A technology for oily sludge and sludge is applied in the field of systems for treating oily sludge, which can solve the problems of poor water absorption and air permeability, deterioration of atmospheric environment quality, occupation of large land and other problems, and achieve the effect of eliminating harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

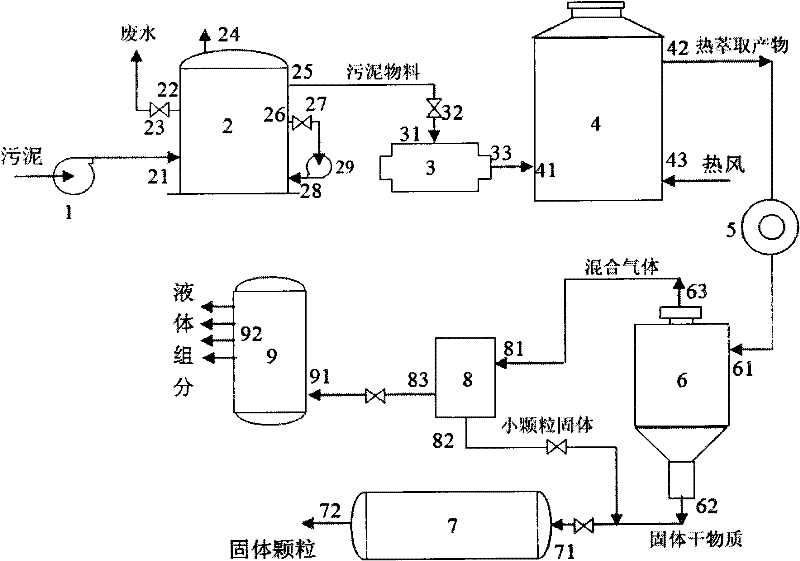

[0061] Use a system consisting of a sludge pump 1, an air flotation concentration device 2, a screw conveying device 3, a thermal extraction device 4, an induced draft fan 5, a cyclone separation device 6, a dust removal device 8, a granulation device 7 and a fractionation device 9 to treat oily dirt Mud is processed.

[0062] Wherein, the oily sludge is waste resin, and 100 parts by weight of waste resin contains 35 parts by weight of organic matter, 55 parts by weight of water and 10 parts by weight of solid.

[0063] The oily sludge is supplied to the air flotation concentration device 2 through the sludge pump 1, and the pumped sludge flow rate of the sludge pump 1 is 20m 3 / h, the outlet pressure of the sludge pump 1 is 0.5MPa.

[0064] Oily sludge is carried out air flotation concentration in the air flotation concentration device 2, the air flotation concentration device 2 includes a feed port 21, a water discharge port 22, a gas discharge port 24 and a sewage discharg...

Embodiment 2

[0073] Process oily sludge according to the method of embodiment 1, the difference is: the pumping sludge flow rate of sludge pump 1 is 30m 3 / h, the outlet pressure of the sludge pump 1 is 0.7MPa; when the air flotation concentration is added, the air bubbles with a particle size of 30-80 μm are added and the content of the air bubbles in the area where the sludge is in contact with the air bubbles is 10.5 mg / L; The water content of the sludge material discharged from the mud discharge port 25 is 85%; the water content of the sludge material discharged from the discharge port 33 of the screw conveyor 3 is 53%; the treatment capacity of the air flotation concentration device 2 is 30m 3 / h; the flow of water discharged from the outlet 22 is 10.5m 3 / h, the pressure of the pressure reducing valve is set to 0.32MPa of the outlet pressure of the sludge pump 1; the inlet wind speed of the cyclone separation device 6 is 10m / s; the pressure drop is 0.075Mpa.

Embodiment 3

[0075] Process oily sludge according to the method of embodiment 1, the difference is: the pumping sludge flow rate of sludge pump 1 is 40m 3 / h, the outlet pressure of the sludge pump 1 is 1.0MPa; air bubbles with a particle size of 10-40 μm are added during air flotation concentration; the water content of the sludge material discharged from the sludge discharge port 25 is 70%; The water content of the sludge material discharged from the outlet 33 of the conveying device 3 is 50%; the processing capacity of the air flotation concentration device 2 is 40m 3 / h; the flow of water discharged from the outlet 22 is 20m 3 / h, the pressure of the pressure reducing valve is set to 0.105MPa of the outlet pressure of the sludge pump 1; the inlet wind speed of the cyclone separation device 6 is 12m / s; the pressure drop is 0.1Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com