Method for removing and recycling volatile alcohol organic matters in water

A recovery method and organic matter technology, applied in chemical instruments and methods, organic chemistry, separation/purification of hydroxyl compounds, etc., can solve problems such as increased impact, operating impact, discontinuous stripping, etc., to reduce condensation and improve Flux, the effect of reducing the effect of wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

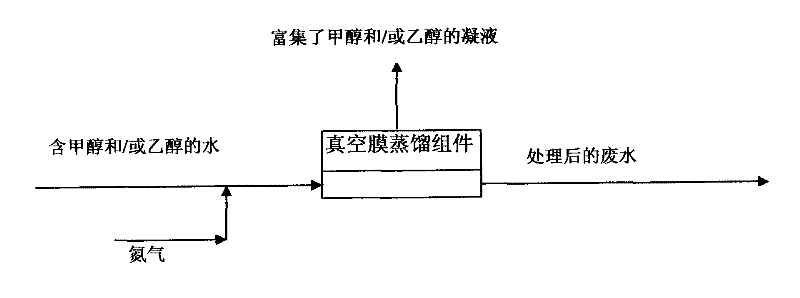

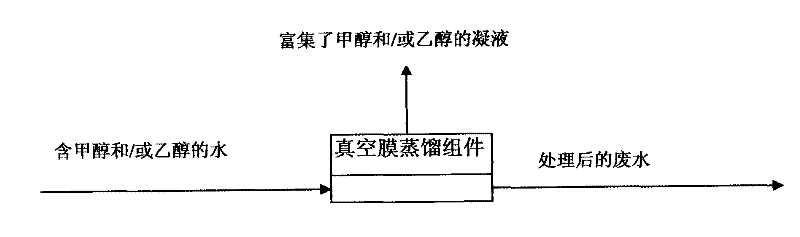

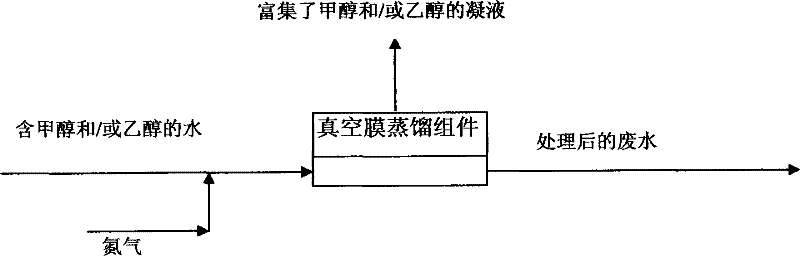

[0058] The effluent of the methanol distillation tower containing 0.55wt% methanol is treated by air-lift vacuum membrane distillation. The main water quality characteristics are: water 99.15wt%, methanol 0.55wt%, ethanol 2370mg / L, isopropanol 170mg / L, n-propanol 130mg / L, n-butanol 30mg / L, isoamyl alcohol 60mg / L, n-pentanol 30mg / L, isooctane 40mg / L, solid content 12mg / L, others 120mg / L, clear appearance, pH 6 ~8. For a schematic diagram of the process, see figure 1 .

[0059] The membrane module used is polyvinylidene fluoride hydrophobic membrane module. Firstly, nitrogen gas is mixed into the water through the gas mixing device, the gas-water volume ratio is 0.2:1, and the water temperature is 65°C. The mixed water enters the inlet side of the membrane module, its average flow velocity in the fiber is 0.6m / s, and the vacuum degree of the cold side of the membrane module is -0.08MPa.

[0060] Since the pressure on the outlet side of the membrane module is lower than the s...

Embodiment 2

[0063] The water containing 5.0wt% methanol was treated by air-lift vacuum membrane distillation. The water was the condensed water on the permeate side of Example 1. The concentration of methanol was 5.0wt%, and the concentration of ethanol was 1.7wt%. For a schematic diagram of the process, see figure 1 .

[0064] The membrane module used is polyvinylidene fluoride hydrophobic membrane module. Firstly, nitrogen gas is mixed into the water through the gas mixing device, the gas-water volume ratio is 0.5:1, and the temperature is 45°C. The mixed water enters the inlet side of the membrane module, its average flow velocity in the fiber is 0.3m / s, and the vacuum degree of the cold side of the membrane module is -0.08MPa.

[0065] After passing through the gas condensation, the concentration of methanol in the condensate is 46wt%, enriched by 9.2 times, and the concentration of ethanol is 12wt%, enriched by 7.1 times; the concentration of methanol in the waste water after treat...

Embodiment 3

[0067] The effluent of the methanol distillation tower containing 0.55wt% methanol is treated by air-lift vacuum membrane distillation. The schematic diagram of the process flow is shown in figure 1 .

[0068] The composition of water is the same as in Example 1.

[0069] The membrane module used is a polypropylene hydrophobic membrane module. Firstly, air is mixed into the water through an air mixing device, the air-water volume ratio is 0.5:1, and the temperature is 45°C. The mixed water enters the inlet side of the membrane module, its flow velocity in the membrane fiber is 0.6m / s, and the vacuum degree of the cold side of the membrane module is -0.08MPa.

[0070] After passing through the gas condensation, the concentration of methanol in the condensate was measured to be 5.5wt%, which was enriched by 10 times, and the concentration of ethanol was 1.9wt%, which was enriched by 8 times; the concentration of methanol in the treated waste water was 0.03wt%, The concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com