Glass mould deep hole processing machine tool

A technology for processing machine tools and glass molds, which is applied to metal processing equipment, drilling tool accessories, manufacturing tools, etc. It can solve problems such as easy heating of tools, direction deviation, and rough inner walls of deep holes, so as to save reprocessing steps and avoid deep holes. Hole position error, the effect of avoiding roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

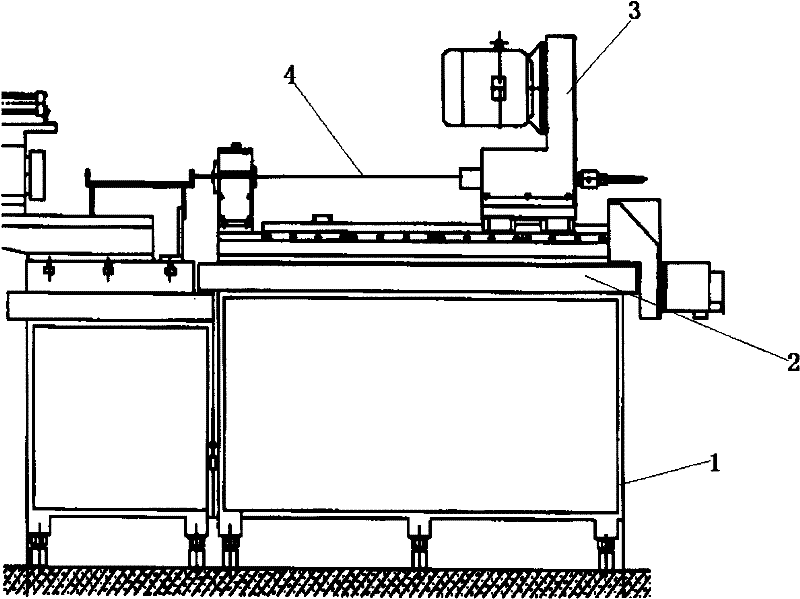

[0016] like figure 1 As shown, a glass mold deep hole processing machine tool includes a bed 1, a workbench 2, a headstock 3 and a tool 4 arranged on the headstock 3, the workbench 2 is arranged on the bed 1, and the workbench 2 A spindle box 3 is arranged on it, and the cutter 4 is a single-edged drill.

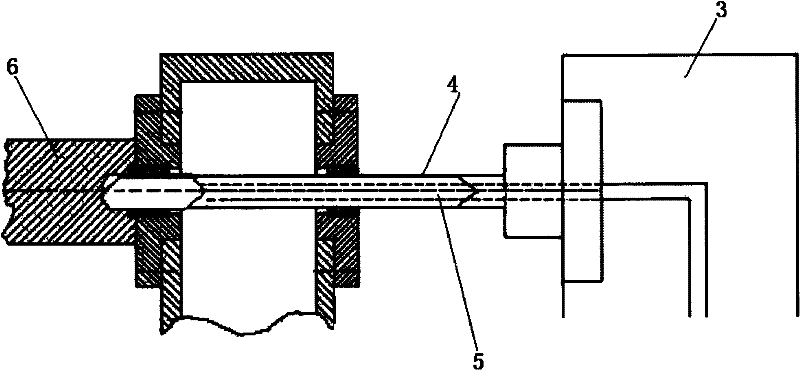

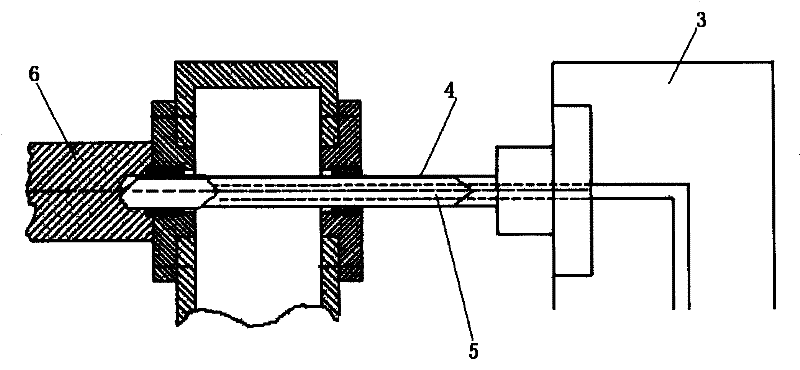

[0017] like figure 2 As shown, an oil delivery pipe 5 is formed inside the single-edged drill, and the oil delivery pipe 5 is connected to the hydraulic device through the headstock 3 .

[0018] The cutting tool of the machine tool of the present invention avoids heat and deformation during processing, and only needs to process the processing hole of the mold 6 once, which solves the position error of the deep hole caused by bidirectional processing, and the inside of the processing hole has a better finish.

[0019] The above embodiments do not limit the present invention in any way, and all technical solutions obtained by means of equivalent replacement or equivalent tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com